Concrete compaction anti-cracking agent

A technology of anti-cracking agent and concrete, which is applied in the field of high-performance dense anti-cracking agent, can solve the problems of design expansion performance, easy decomposition, and small compensation effect, so as to improve crack resistance and durability, overcome heavy dependence, expansion performance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this embodiment, the concrete compacting anti-cracking agent components (by weight) include: 30% light-burned magnesium oxide, 30% calcium oxide-calcium sulfoaluminate double expansion source expanded clinker, gypsum (natural purity of 85%) Anhydrite) 15%, specific surface area is 500m 2 / kg of stone powder 30%.

[0070] Among them, light burned magnesia and double expansion source expanded clinker can be prepared by the following method: light burned magnesia is the active reaction time obtained by calcination of 100% magnesite (average particle size 10-30mm) at 850°C for 60 minutes Light-burned magnesia, calcium oxide-calcium sulfoaluminate double expansion source expanded clinker for 100 seconds is obtained by calcining limestone, iron powder, gypsum and bauxite in a rotary kiln at 1300°C, and the composition is SiO 2 3.83%, Al 2 O 3 6.65%, Fe 2 O 3 1.80%, CaO75.8%, MgO 1.57%, SO 3 8.81%, of which 55.5% f-CaO.

Embodiment 2

[0072] In this embodiment, the concrete compacting anti-cracking agent components (by weight) include: 40% light-burned magnesium oxide, 20% calcium oxide-calcium sulfoaluminate double expansion source expanded clinker, gypsum (natural purity of 85%) Anhydrite) 15%, stone powder (specific surface area is 500m 2 / kg of limestone powder) 25%.

[0073] Among them, light-burned magnesia is light-burned magnesia obtained by calcining magnesite at 850°C with an active reaction time of 100 seconds. Calcium oxide-calcium sulfoaluminate double expansion source expanded clinker is obtained by combining limestone, iron powder, Gypsum and bauxite were calcined in a rotary kiln at 1300°C (the composition is the same as in Example 1).

Embodiment 3

[0075] In this embodiment, the concrete compacting anti-cracking agent components (by weight) include: 55% light burned magnesium oxide, 15% calcium oxide-calcium sulfoaluminate double expansion source expanded clinker, gypsum (natural purity 85% Anhydrite) 10%, stone powder (specific surface area is 500m 2 / kg of limestone powder) 20%.

[0076] Among them, magnesia is light-burned magnesia obtained by calcining magnesite at 850°C with an active reaction time of 100 seconds. Calcium oxide-calcium sulfoaluminate double expansion source expanded clinker is obtained by mixing limestone, iron powder, gypsum and The bauxite is calcined in a rotary kiln at 1300°C (the composition is the same as in Example 1).

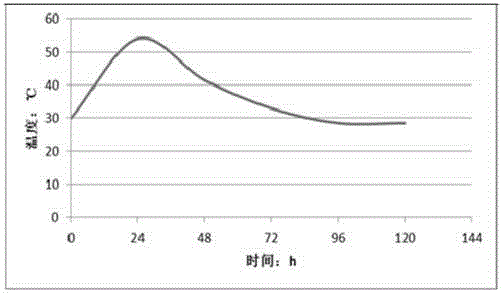

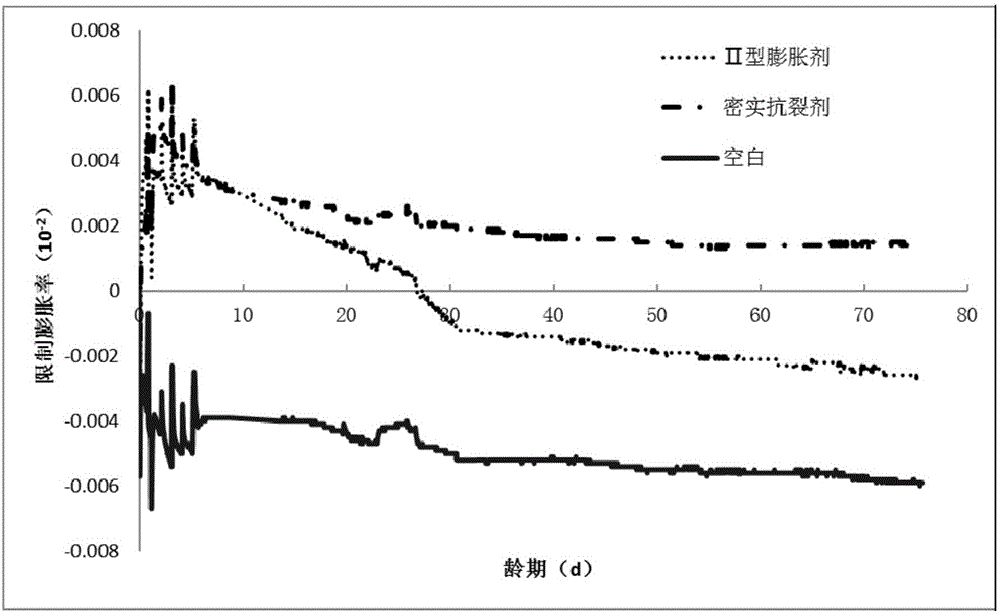

[0077] The concrete formula used to test the anti-cracking agents of Examples 1, 2, and 3 adopts the common side wall formula, that is, the concrete grade is C35, and the total amount of glue is 380kg / m 3 , Water-binder ratio 0.43, mixed with 10% solid content polycarboxylic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com