Stretchable slow-expansion acrylic resin as well as preparation process and application thereof

A technology of acrylic resin and preparation process, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of fast water absorption expansion rate, broken, unreachable, etc., achieve controllable expansion, change poor shear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

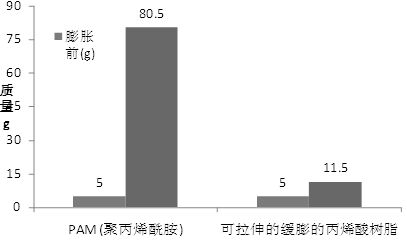

[0038] This embodiment provides a stretchable slow-swelling acrylic resin, which is obtained by free radical polymerization of polyacrylamide and linear polymer in aqueous solution.

[0039] In the stretchable slow-swelling acrylic resin provided by the present invention, the first cross-linked network formed by polyacrylamide and the second network of the linear polymer solution are polymerized by free radical aqueous solution to prepare a highly elastic and slow-swelled acrylic resin , to overcome the current conventional polyacrylamide, unstable, weak, anti-fatigue, poor shear resistance defects.

Embodiment 2

[0041] On the basis of Example 1, this example provides a stretchable slow-swelling acrylic resin, the mass percentage of the polyacrylamide is 17-36%, and the mass percentage of the linear polymer is 2-5% %, the balance is water.

[0042] Using polyacrylamide as the first cross-linked network and linear polymer as the second network, an interpenetrating network hydrogel is formed.

Embodiment 3

[0044] On the basis of Example 2, this example provides a stretchable slow-swelling acrylic resin, the mass percent of the polyacrylamide is 35.5%, the mass percent of the linear polymer is 5%, and the water is 59.5%.

[0045] In this example, polyacrylamide is obtained by crosslinking reaction of 20% acrylamide, 10% acrylic acid, 0.5% tetramethylethylenediamine crosslinking agent and 5% long carbon chain type functional association monomer. Acrylamide; the linear polymer is a mixture of carrageenan and xanthan gum with a mass ratio of 3:1.

[0046] The preparation process is as follows:

[0047] Step 1) Add the formulated amount of acrylamide, acrylic acid, tetramethylethylenediamine crosslinking agent, and long carbon chain functional associative monomer to some water to form a polyacrylamide solution as the first crosslinking network;

[0048]Step 2) Add the formulated amount of linear polymer to the remaining water at 80~100°C, place it on a magnetic stirrer and stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com