Microemulsion Conditioning and Flooding System and Its Application

A system and microemulsion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low oil displacement efficiency, poor temperature resistance and salt resistance, etc., achieve stable control, enhance temperature resistance and salt resistance , Improve the effect of solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

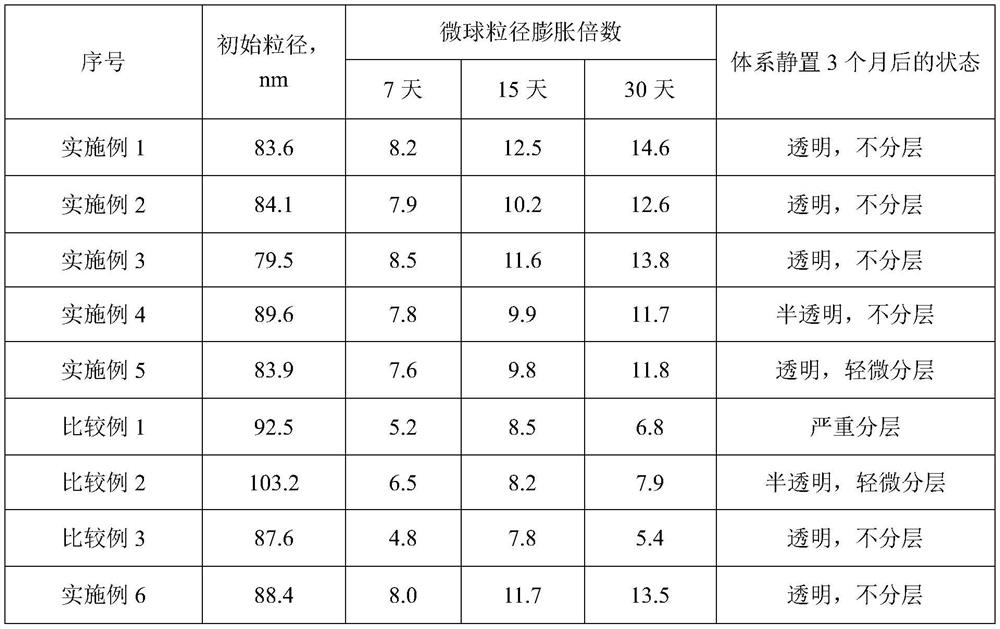

Examples

Embodiment 1

[0050] The polymer microspheres of this embodiment are prepared by polymerizing a reverse-phase microemulsion under the action of a redox composite initiator; the reverse-phase microemulsion, in parts by weight, comprises the following components:

[0051] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0052] b) 10 parts of emulsifier; the emulsifier HLB value is 6.7 (from Span 60 (ie sorbitan monostearate) HLB value 4.7; Tween 80 (polyoxyethylene (20EO) sorbitan monooleic acid Esters) mixed with HLB value 15);

[0053] c) 35 parts of hydrophilic monomers: 18 parts of acrylamide, 6 parts of sodium acrylate, 6 parts of 2-acrylamido-2-sodium methylpropanesulfonate and 5 parts of dimethyl diallyl ammonium chloride composition;

[0054] d) 5 parts of hydrophobic monomers: sodium 2-acrylamido-N-tetradecylsulfonate;

[0055] e) 30 parts of water;

[0056] Wherein, the composite initiator, in terms of the above-mentioned total monomer weight percent, comp...

Embodiment 2

[0094] The polymer microspheres of this embodiment are prepared by polymerizing a reverse-phase microemulsion under the action of a redox composite initiator; the reverse-phase microemulsion, in parts by weight, comprises the following components:

[0095] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0096] b) 10 parts of emulsifier; the emulsifier HLB value is 6.7 (from Span 60 (ie sorbitan monostearate) HLB value 4.7; Tween 80 (polyoxyethylene (20EO) sorbitan monooleic acid Esters) mixed with HLB value 15);

[0097] c) 35 parts of hydrophilic monomers: 18 parts of acrylamide, 6 parts of sodium acrylate, 6 parts of 2-acrylamido-2-sodium methylpropanesulfonate and 5 parts of dimethyl diallyl ammonium chloride composition;

[0098] d) 5 parts of hydrophobic monomers: p-tert-butylstyrene;

[0099] e) 30 parts of water;

[0100] Wherein, the composite initiator, in terms of the above-mentioned total monomer weight percent, comprises the following co...

Embodiment 3

[0115] The polymer microspheres of this embodiment are prepared by polymerizing a reverse-phase microemulsion under the action of a redox composite initiator; the reverse-phase microemulsion, in parts by weight, comprises the following components:

[0116] a) 50 parts of oil-soluble solvent; oil-soluble solvent is white oil;

[0117] b) 10 parts of emulsifier; the emulsifier HLB value is 6.7 (from Span 60 (ie sorbitan monostearate) HLB value 4.7; Tween 80 (polyoxyethylene (20EO) sorbitan monooleic acid Esters) mixed with HLB value 15);

[0118] c) 35 parts of hydrophilic monomers: 18 parts of acrylamide, 6 parts of sodium acrylate, 6 parts of 2-acrylamido-2-sodium methylpropanesulfonate and 5 parts of dimethyl diallyl ammonium chloride composition;

[0119] d) 5 parts of hydrophobic monomers: octadecyl methacrylate;

[0120] e) 30 parts of water;

[0121] Wherein, the composite initiator, in terms of the above-mentioned total monomer weight percent, comprises the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com