Self-compacting concrete for rapid transit railway III-type plate ballastless tracks and preparation method of self-compacting concrete

A technology of slab ballastless track and self-compacting concrete, which is applied in the preparation of self-compacting concrete and the field of self-compacting concrete, can solve the problems of affecting the service life, short development time, and non-adhering joints, etc., and achieves high production efficiency and flow performance. Good, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The above-mentioned preparation method for the self-compacting concrete of Type III slab ballastless track of high-speed railway comprises the following steps:

[0013] ① Prepare raw materials according to the ratio;

[0014] ②Put the stones and sand in the raw materials into the mixer and stir for 120 seconds;

[0015] ③Continue to add cement, fly ash, mineral powder, expansion agent, thickener and shrinkage reducer in the raw materials and stir for 60 seconds;

[0016] ④ Add water reducing agent, slump retaining agent and water and stir for 150 seconds.

Embodiment 1

[0018] Prepare raw materials according to the following mixing ratio (parts by weight):

[0019] 100 parts of ordinary silicate 425# cement, 11 parts of expansion agent, 38.5 parts of fly ash, 20.5 parts of mineral powder, 261 parts of sand with a fineness modulus of 2.3-2.5, 251 parts of stones with a particle size of 5-10mm, and expansion agent 11 parts, 0.04 parts of thickener, 56 parts of water, 1.3 parts of shrinkage reducing agent, 2.3 parts of water reducing agent, 0.37 parts of slump retaining agent.

[0020] Preparation process: Add the stone and sand in the raw material to the mixer and stir for 120 seconds, then add the cement, fly ash, mineral powder, expansion agent, thickener, and shrinkage reducer in the raw material and stir for 60 seconds, and finally add the water reducer and slump retaining agent Stir with water for 150 seconds.

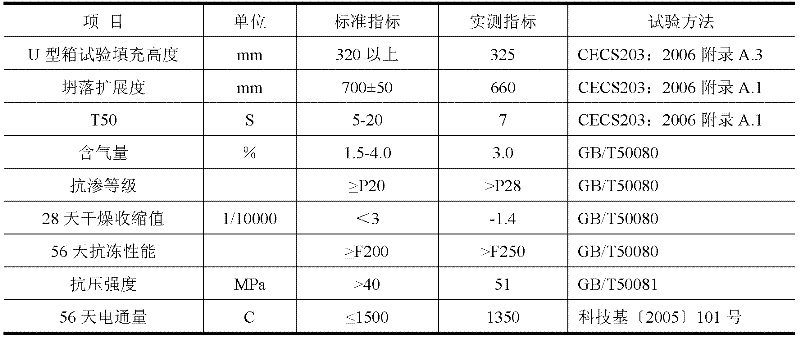

[0021] The main performance indicators are shown in the table below:

[0022]

Embodiment 2

[0024] Prepare raw materials by following proportioning (parts by weight):

[0025] 100 parts of ordinary silicate 425# cement, 11 parts of expansion agent, 38.5 parts of fly ash, 20.5 parts of mineral powder, 277 parts of sand with a fineness modulus of 2.6-2.8, 235 parts of stones with a particle size of 5-10mm, and expansion agent 11 parts, 0.04 parts of thickener, 60 parts of water, 1.3 parts of shrinkage reducing agent, 2.3 parts of water reducing agent, 0.37 parts of slump retaining agent.

[0026] Preparation process: Add the stone and sand in the raw material to the mixer and stir for 120 seconds, then add the cement, fly ash, mineral powder, expansion agent, thickener, and shrinkage reducer in the raw material and stir for 60 seconds, and finally add the water reducer and slump retaining agent Stir with water for 150 seconds.

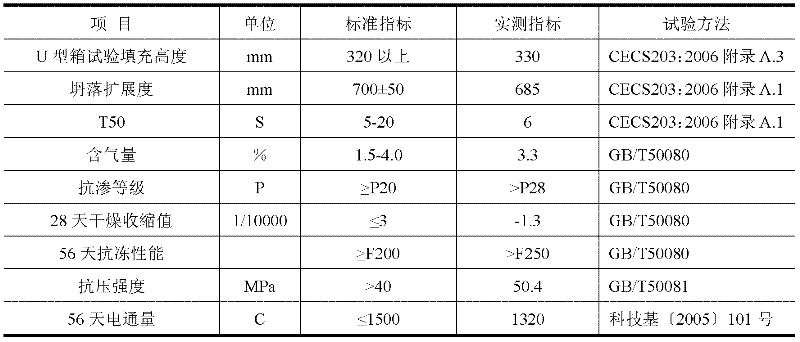

[0027] The main performance indicators are shown in the table below:

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com