A kind of steel bridge deck prefabricated pavement equipment

A technology for steel bridge decks and equipment, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of low efficiency of paving technical means and great influence of construction privacy factors, so as to improve the quality and efficiency of paving, reduce Construction process, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

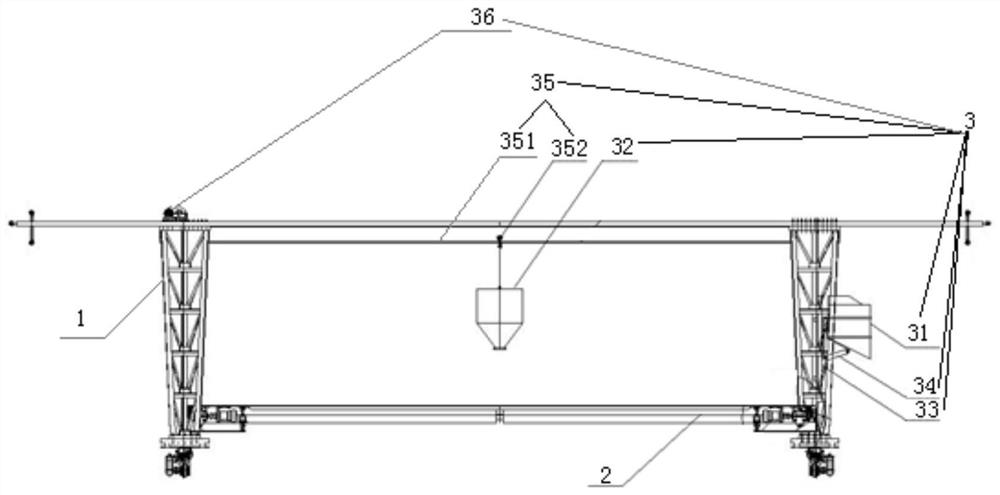

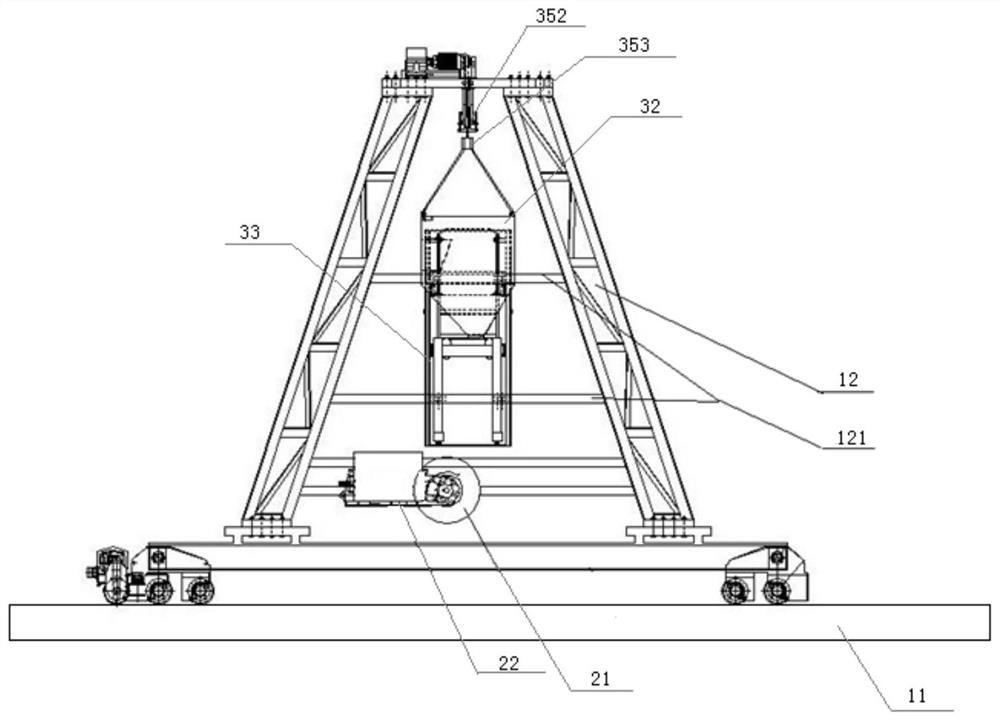

[0048] The invention discloses a steel bridge deck prefabricated paving equipment, comprising a walking frame 1 located on the steel bridge deck, and a paving mechanism for paving the concrete layer of the steel bridge deck is installed on the walking frame 1 2. It is characterized in that the steel bridge deck prefabricated paving equipment further comprises a mobile silo 3 for providing concrete for the paving mechanism 2;

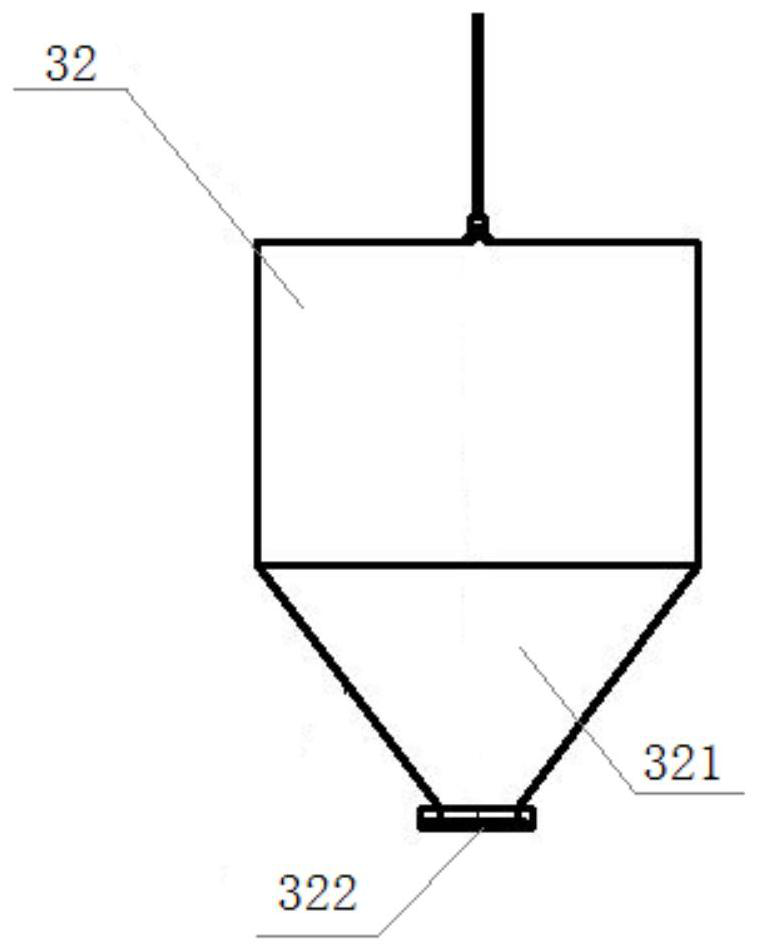

[0049] The moving silo 3 includes a vertical moving silo 31 and a horizontal paving silo 32. The vertically moving silo 31 moves along the walking frame through the lifting mechanism 33 provided on the walking frame 1. 1, when the lifting mechanism 33 lifts the vertically moving silo 31 to the highest position, the height of the top surface of the vertically moving silo 31 from the bridge deck is greater than or equal to the horizontal paving silo. 32 The height of the feeding port from the bridge deck;

[0050] The vertically moving silo 31 is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com