Integrated device for measurement and evaluation of workability of self-compacting concrete

A self-compacting concrete, workability technology, applied in the direction of measuring devices, mechanical devices, flow characteristics, etc., can solve the problems that cannot reflect the characteristics and requirements of self-compacting concrete self-compacting, poor sensitivity of test results, complicated operation, etc. , to achieve the effect of reducing human subjective influence factors, reliable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

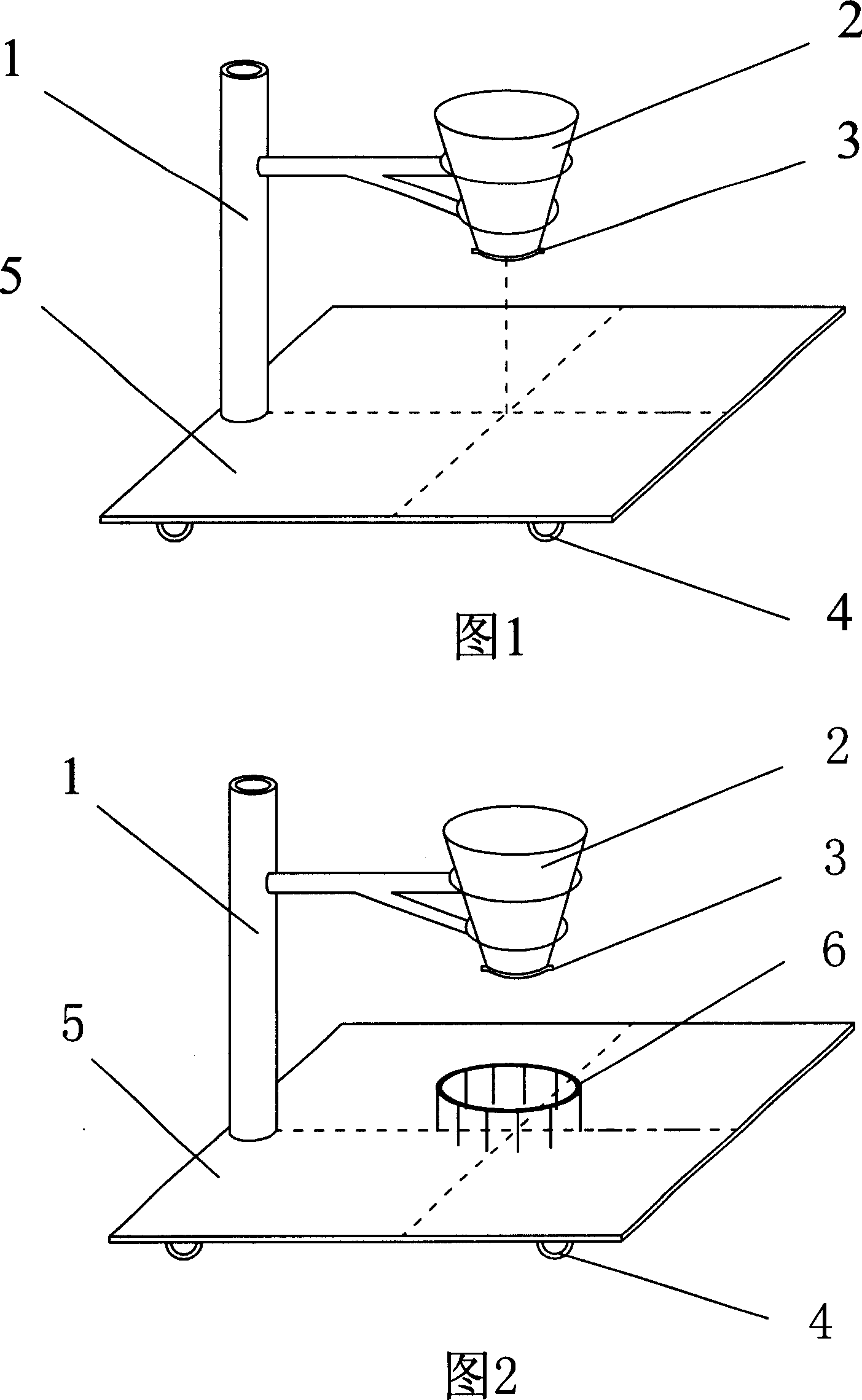

[0024] Referring to Fig. 1 and Fig. 2, the present invention adopts support 1 to prop up and fix the inverted cone cylinder 2 (the size is the same as the slump cylinder), the axial center line of the inverted cone cylinder 2 is perpendicular to the horizontal plane and the small diameter mouth end Downwards, the small-diameter mouth end is provided with a valve 3, and the vertical distance from the lower port of the undercut cone 2 to the flat plate 5 is determined to be 30 cm. This distance is determined by the test. The axial centerline of the undercut cone 2 Coinciding with the vertical center line of the flat panel 5, the support 1 and the flat panel 5 are all installed on the wheeled trolley 4.

[0025] (1), referring to Fig. 1, install the instrument according to the experimental device shown in Fig. 1, the valve 3 of the lower port of the inverted cone cylinder 2 is closed, then the concrete mixture sample is packed in the inverted cone cylinder 2, After the mixture is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com