Self-compacting concrete prepared from concrete mixing station waste slurry

A self-compacting concrete and mixing plant technology, applied in the field of building materials, can solve the problems of low utilization rate, large amount of cementitious materials, inability to handle concrete waste slurry, etc., and achieve the effect of reducing costs and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

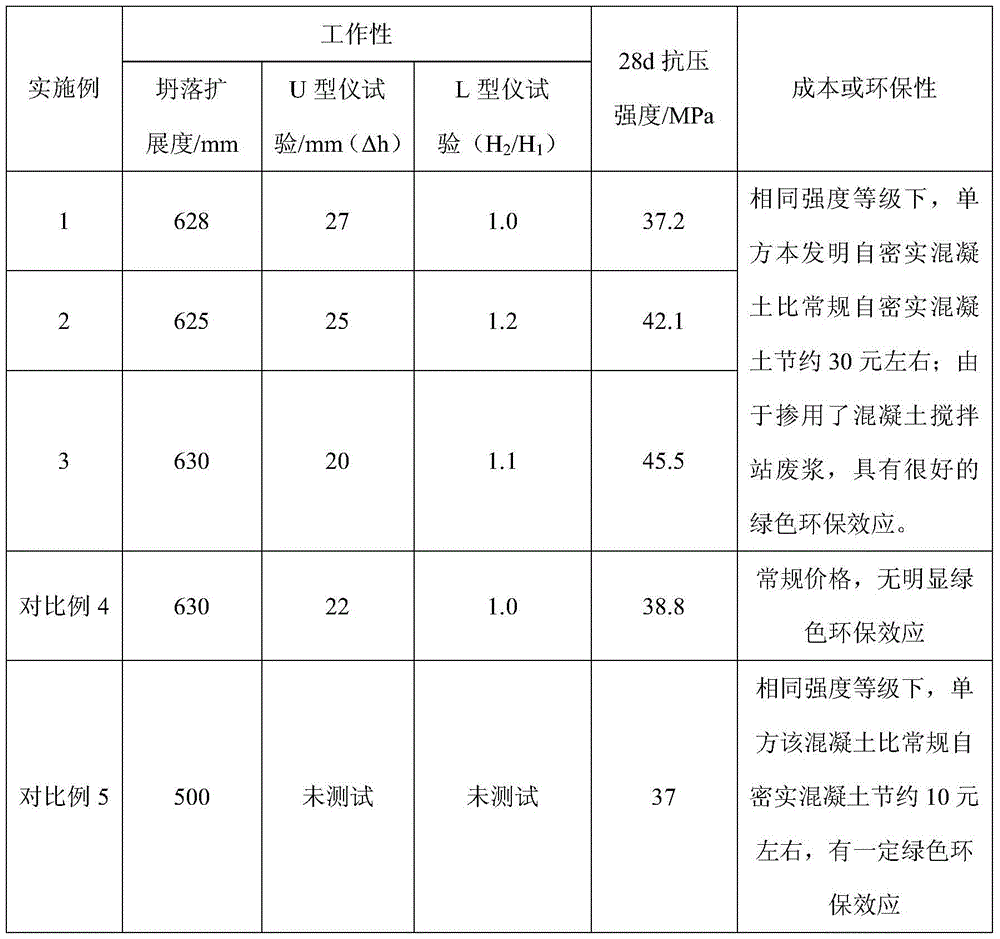

[0040] Calculated by weight, it includes 280 parts of cement, 145 parts of fly ash, 90 parts of waste slurry from concrete mixing plant, 820 parts of river sand, 925 parts of gravel, 4.6 parts of water reducer and 132 parts of water.

[0041] Performance testing: See Table 1 for workability and 28d compressive strength.

Embodiment 2

[0043] Calculated by weight, it includes 300 parts of cement, 150 parts of fly ash, 100 parts of waste slurry from concrete mixing plant, 800 parts of river sand, 920 parts of gravel, 5.2 parts of water reducer and 130 parts of water.

[0044] Performance testing: See Table 1 for workability and 28d compressive strength.

Embodiment 3

[0046] Calculated by weight, it includes 310 parts of cement, 160 parts of fly ash, 110 parts of waste slurry from concrete mixing plant, 800 parts of river sand, 900 parts of gravel, 5.4 parts of water reducer and 118 parts of water.

[0047] Performance testing: See Table 1 for workability and 28d compressive strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com