Poly carboxylic acid series compound water reducing agent used for hydraulic self-compacting concrete and preparation method and application

A self-compacting concrete, polycarboxylic acid-based technology, applied in the field of water-reducing agent, can solve the problem that the performance requirements of hydraulic self-compacting concrete cannot be well met, and can fill the market gap, improve workability, and have great application value. and market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

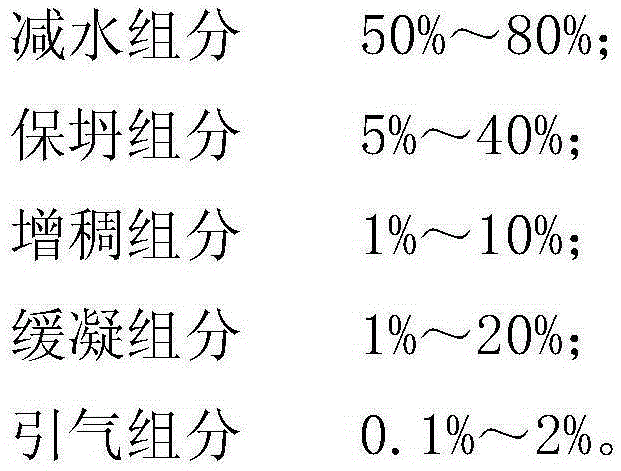

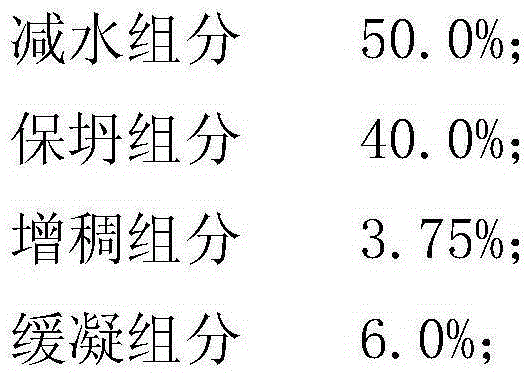

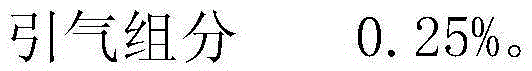

[0029] The composition and ratio of polycarboxylate compound water reducer for hydraulic self-compacting concrete are as follows:

[0030] Low air-entraining polyether polycarboxylate superplasticizer 258 kg, polyether polycarboxylate slump retaining agent 110 kg, methyl cellulose 5 kg, xanthan gum 5 kg Hydroxy carboxylate 10 kg, polysaccharide 10 kg, polyether 2 kg of similar air-entraining agent.

Embodiment 2

[0032] This example provides a polycarboxylate composite water reducer for hydraulic self-compacting concrete suitable for direct use, which is obtained by uniformly dispersing all the components in Example 1 in 600 kg of water. When mixing, the water-reducing component and the slump-preserving component are added into the water and mixed evenly, then the thickening component, retarding component and air-entraining component are added in sequence, and mixed evenly.

[0033] Since the water reducer is usually prepared into a liquid with a certain concentration of each effective component and water when it is used. Therefore, this embodiment provides a compound water reducer with a common concentration that can be used directly. Since both the low air-entraining polyether polycarboxylate water reducer and the polyether polycarboxylate slump retaining agent in Example 1 are mother liquors, the two components are now mixed in water when mixing, and then the other components Mix i...

Embodiment 3

[0035] When the water reducer is used, the components are generally uniformly mixed in water to obtain a liquid water reducer and then used in concrete. Therefore, in this example, the water reducer of Example 2 is used in concrete, and the amount of the water reducer of Example 2 is 1.5% to 2.5% of the total weight of cementitious materials (including cement and admixtures). When the water reducer of this embodiment is used in concrete, the amount equivalent to the solid mass is generally 0.2% to 0.6% of the total weight of the cementitious material of the concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com