Application and processing method of cassava whole flour

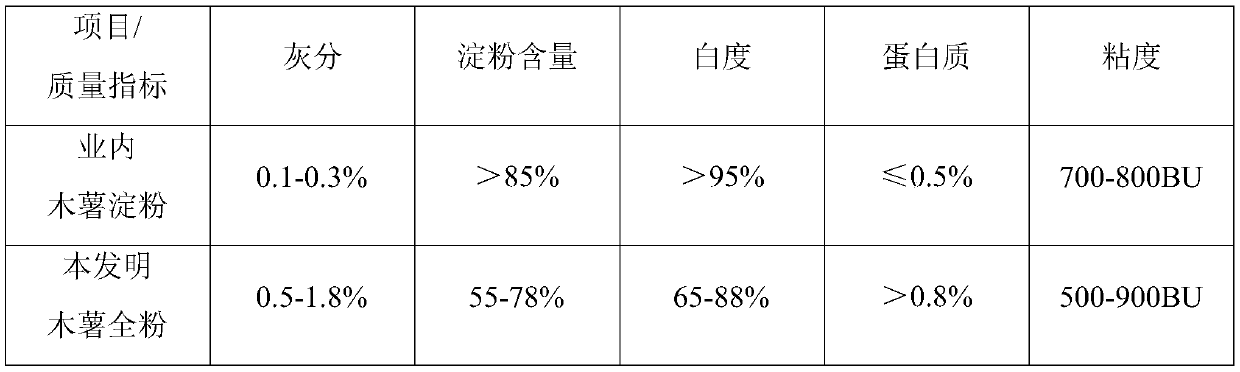

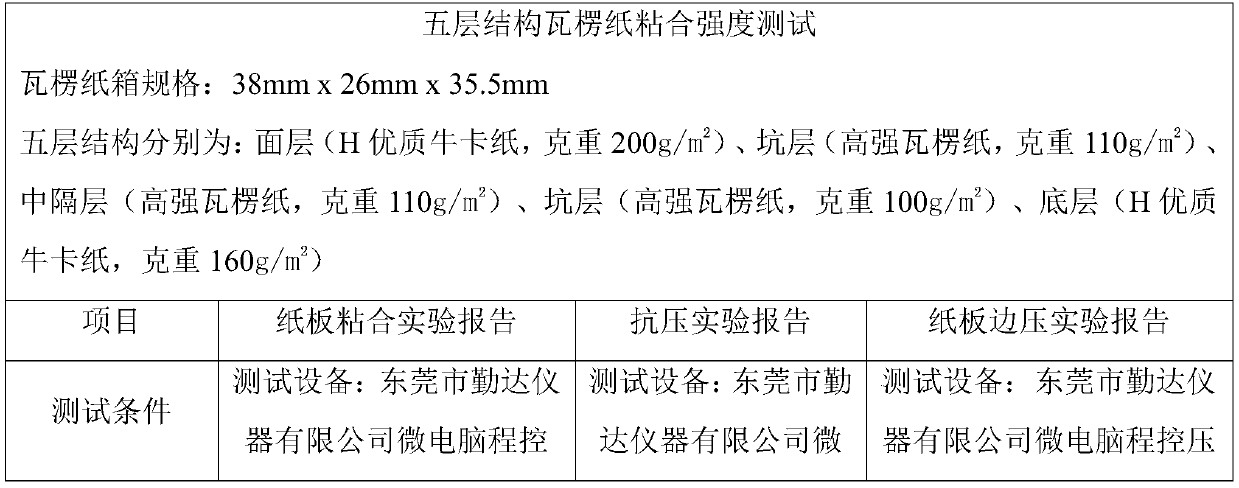

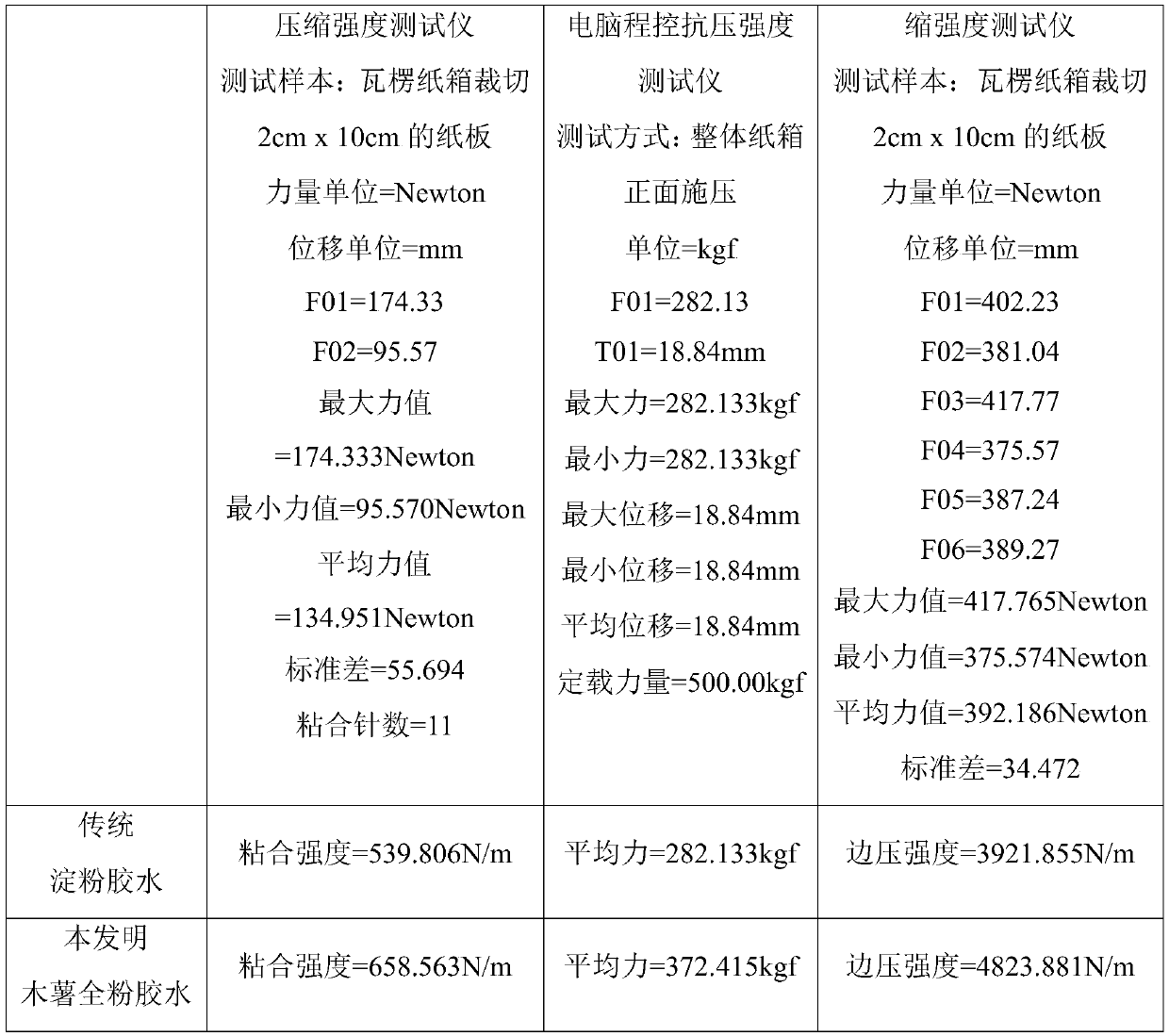

A technology of cassava whole flour and processing method, which is applied in the directions of starch adhesives, adhesive additives, polymer adhesive additives, etc. Application scope limitation and other issues, to achieve the effects of stable cardboard processing quality, improved edge pressure strength, and increased vehicle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of application of whole cassava powder of this embodiment, whole cassava powder is used for preparing glue. The quality indexes of the whole cassava powder are: ash content 0.8%, starch content 56%, whiteness 71%, viscosity 620BU. The cassava fiber content in the whole cassava powder is 5% of the weight of the whole cassava powder. The glue prepared from whole cassava flour in this embodiment is applied to adhesive glue for corrugated cardboard. The main component of the adhesive glue for corrugated cardboard is whole cassava flour, and also includes caustic soda, borax and water.

[0053] A kind of processing method of whole cassava flour of the present embodiment, the processing method of the whole cassava powder that is used to prepare glue comprises the following steps:

[0054] (3) impurity removal, fresh cassava surface cleaning and impurity removal;

[0055] (4) slicing or shredding, drying or drying, so that the cassava moisture is controlled within 12%...

Embodiment 2

[0058] A kind of application of whole cassava powder of this embodiment, whole cassava powder is used for preparing glue. The quality indexes of the whole cassava powder are: ash content 1%, starch content 60%, whiteness 72%, viscosity 650BU. The cassava fiber content in the whole cassava powder is 15% of the weight of the whole cassava powder.

[0059] The glue prepared from the whole cassava powder of the present embodiment is applied to the plywood glue, that is, the whole cassava powder is used to prepare the plywood glue. The main component of the plywood glue is the whole cassava powder. 35%-90%, the remaining raw materials of the plywood glue formula are conventional components.

[0060] A kind of processing method of whole cassava flour of the present embodiment, the processing method of the whole cassava powder that is used to prepare glue comprises the following steps:

[0061] (5) impurity removal, fresh cassava surface cleaning and impurity removal;

[0062] (6)...

Embodiment 3

[0065] A kind of application of whole cassava powder of this embodiment, whole cassava powder is used for preparing glue. The quality indexes of the whole cassava powder are as follows: ash content 1.1%, starch content 70%, whiteness 75%, viscosity 680BU. The cassava fiber content in the whole cassava powder is 20% of the weight of the whole cassava powder.

[0066] The glue prepared by the cassava whole powder of the present embodiment is applied in papermaking mounting surface sizing, that is, the whole cassava powder is used to prepare papermaking mounting surface sizing, and the main component of the papermaking mounting surface sizing is cassava whole powder, and the cassava whole powder The addition amount is 35%-90% of the total weight of the solid content of the formulation, and the rest of the raw materials of the papermaking lamination sizing formulation are conventional materials.

[0067] A kind of processing method of whole cassava flour of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com