Composite high-early strength blending material for unballasted track plate and use thereof

A ballastless track and admixture technology, applied in the field of building materials, can solve the problems of not meeting the technical requirements of ballastless track slabs, limited strength growth, and durability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation: The amount of each component material in the 50kg admixture (excluding the activator) is:

[0028] A (silica fume) 70% 35kg

[0029] B (calcium oxide) 10% 5kg

[0030] C (ground zeolite powder, specific surface area is 400m 2 / kg~800m 2 / kg) 10% 5kg

[0031] D (fly ash) 10% 5kg

[0032] F alcohol amines (triethanolamine) 3 / 10,000 15g

[0033] Fully mix the above components A, B, C, D, and F to obtain Wood Example Admixture 1.

[0034] Admixture performance testing:

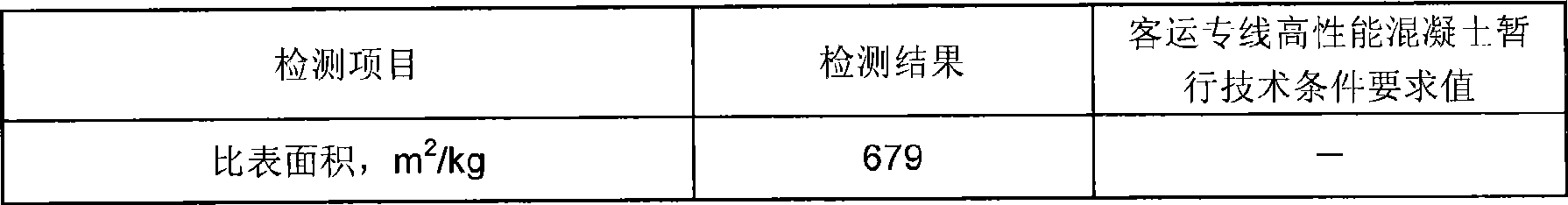

[0035] According to the standard (GB / T 18736) of finely ground slag powder, the composite early-strength admixture (product code ZYY) of Example 1 was tested, and the specific performance indicators are shown in Table 1. The analysis shows that the admixture fully meets the relevant regulations in the "Temporary Technical Conditions for High Performance Concrete for Passenger Dedicated Lines".

[0036] Table 1 Performance index of compound early-strength admixture ZYY

[0037]

[00...

Embodiment 2~ Embodiment 6

[0046] In the same manner as Example 1, the admixture is prepared by the composition of Table 4 (by preparing 100kg admixture, excluding activator, calculation), and in the same way as Example 1, performance testing is carried out, and the detection values are shown in Table 5 :

[0047] Table 4: Admixture composition

[0048]

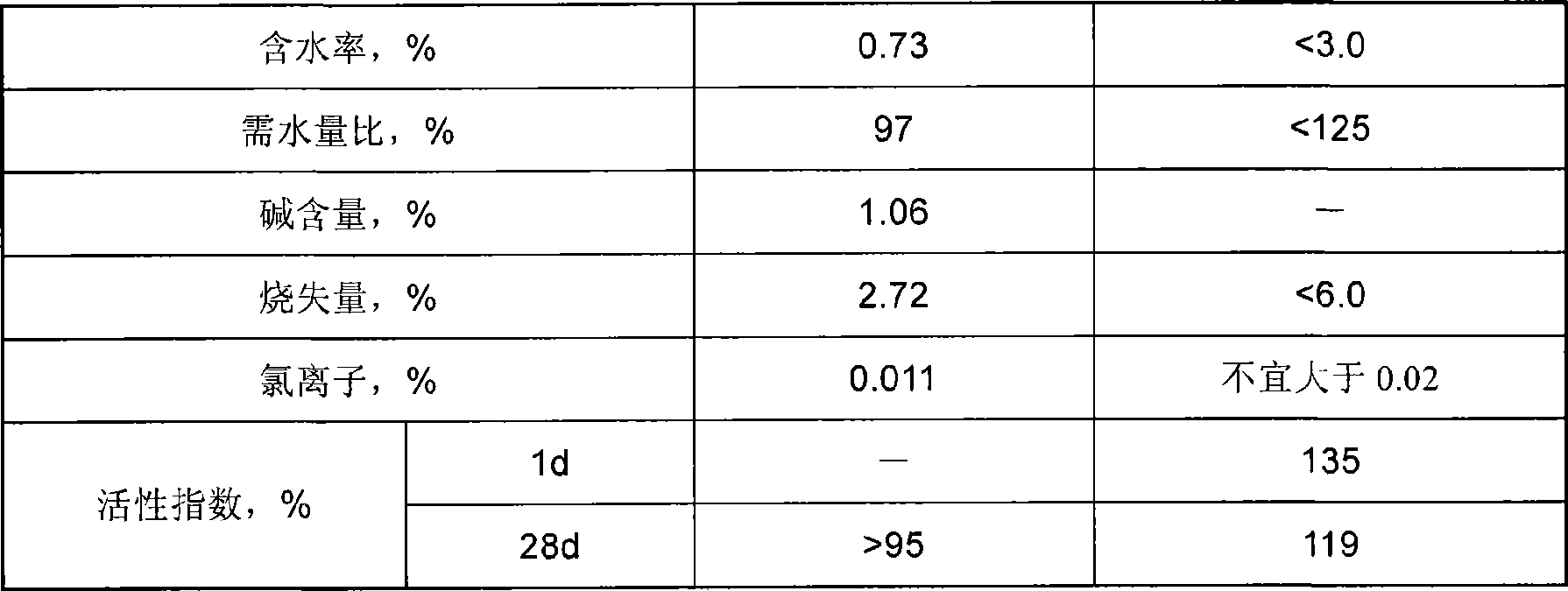

[0049] Table 5: Example admixture performance detection

[0050]

[0051] It can be seen that the admixture assembled in the method of the present invention all meets the requirements of the "Temporary Technical Conditions for High-Performance Concrete for Passenger Dedicated Lines".

[0052] The application of admixture of the present invention:

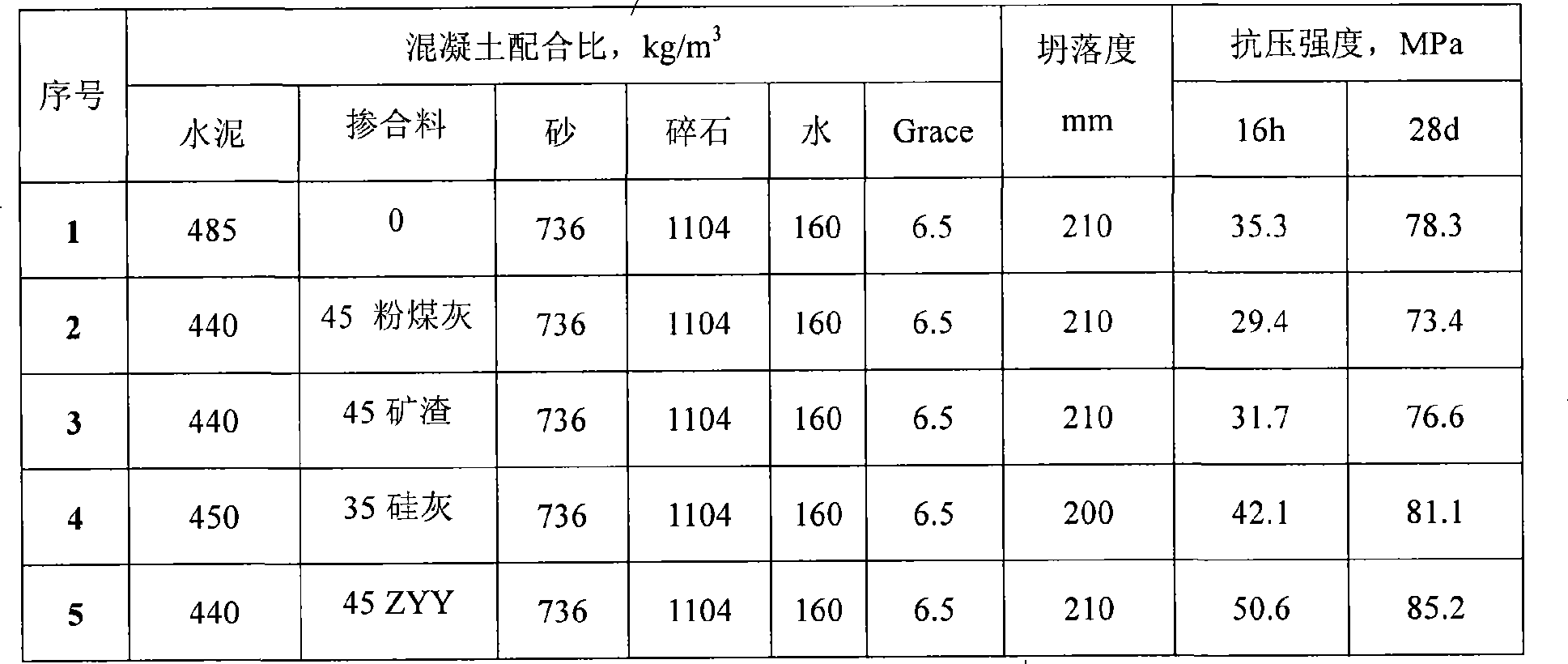

[0053] The admixture ZYY prepared by the present invention is respectively used in the preparation of concrete for CRTS I and CRTS II ballastless track slabs. The concrete performance index test is carried out with reference to GB / T 50080 and GB / T 50081. Ballastless track slabs The performance tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com