Preparation and construction method of composite admixture, compounding method and coal mine outer shaft wall concrete

A composite admixture and concrete technology, which is applied in the field of freezing well sinking, can solve the problems of reducing the reliability of concrete and reducing the strength of concrete, and achieve the effects of strengthening strength, improving early strength, and improving particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following combined with preferred embodiments, the preparation and preparation of the composite admixture, compounding method and coal mine outer shaft wall concrete proposed in accordance with the present invention The specific implementation, structure, features and effects of the construction method are described in detail later. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. In addition, specific features, structures, or characteristics in one or more embodiments may be combined in any suitable form.

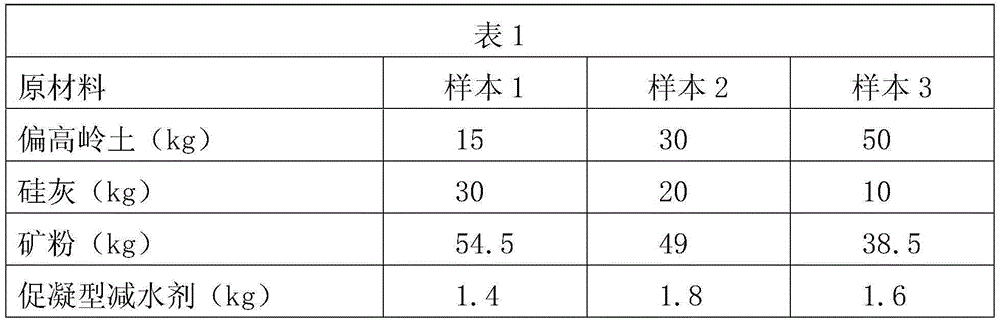

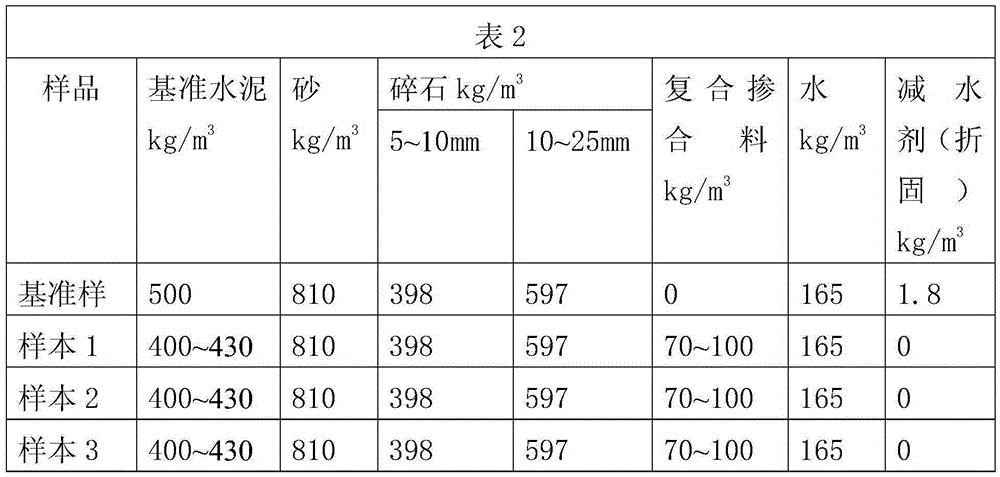

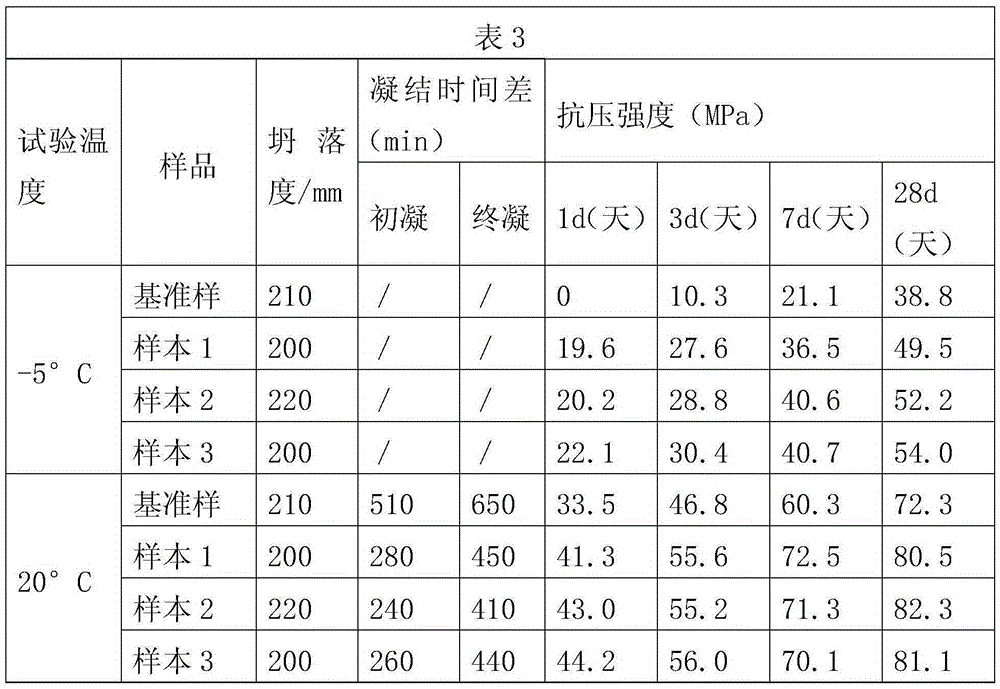

[0059] As shown in Fig. 1, a composite admixture proposed in the first embodiment of the present invention includes a mineral admixture and an accelerator type water reducer. Wherein, the mass of the mineral admixture accounts for 98-99% of the total mass of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com