Medium-and-low-temperature curing single-component epoxy adhesive low in linear expansion coefficient and preparation method thereof

A linear expansion coefficient, epoxy adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of high temperature curing and high linear expansion coefficient of one-component epoxy adhesives, saving resources, reducing Internal stress, the effect of avoiding strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

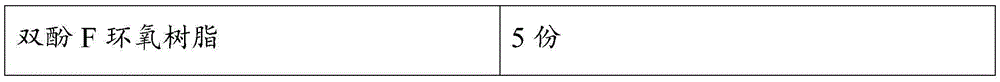

[0031] Embodiment 1 one-component epoxy adhesive

[0032] The reaction components are as follows,

[0033]

[0034]

[0035] According to the above-mentioned component weight table, the preparation method is as follows,

[0036] 1. Add bisphenol F epoxy resin, multifunctional epoxy resin, diluent, pigment, surfactant, coupling agent, and stir at low speed for a certain period of time;

[0037] 2. Add silicon micropowder, raise the temperature to 35°C, stir at a high speed and vacuumize, after stirring for 50 minutes, stop stirring, turn off the vacuum, and start to lower the temperature;

[0038] 3. After the temperature drops to 25°C, add latent curing agent, stir in vacuum at high speed for 15 minutes, and ensure that the temperature of the whole experiment is controlled below 35°C; the one-component epoxy adhesive is obtained.

Embodiment 2

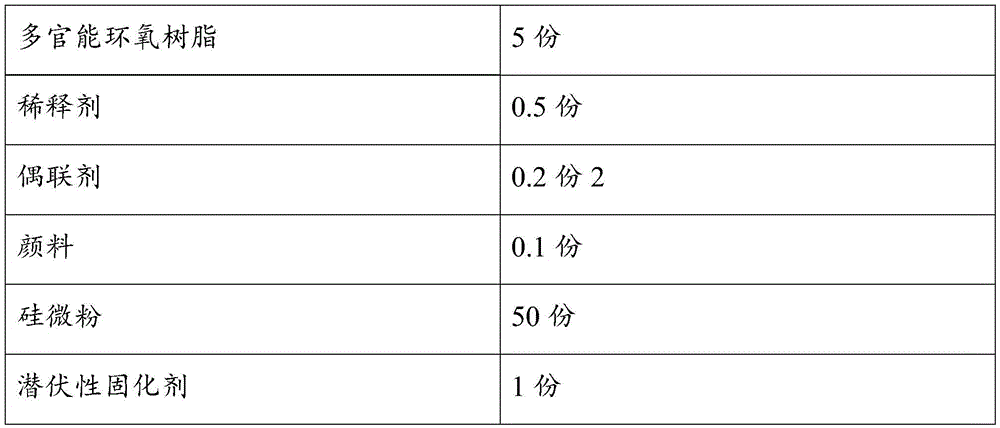

[0039] Embodiment 2 one-component epoxy adhesive

[0040] The reaction components are as follows,

[0041]

[0042]

[0043] According to the above-mentioned component weight table, the preparation method is as follows,

[0044] 1. Add bisphenol F epoxy resin, multifunctional epoxy resin, diluent, pigment, surfactant, coupling agent, and stir at low speed for a certain period of time;

[0045] 2. Add silicon micropowder, heat up to 60°C, stir at a high speed and vacuumize, after stirring for 70 minutes, stop stirring, turn off vacuuming, and start to lower the temperature;

[0046] 3. After the temperature drops to 35°C, add latent curing agent, stir in vacuum at high speed for 30 minutes, and ensure that the temperature of the entire experiment is controlled below 35°C; the one-component epoxy adhesive is obtained.

Embodiment 3

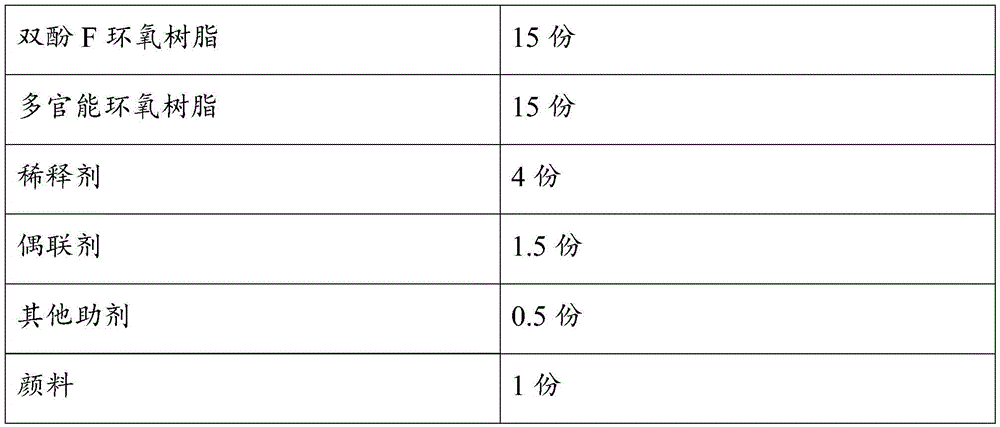

[0047] Embodiment 3 one-component epoxy adhesive

[0048] The reaction components are as follows,

[0049] Bisphenol F epoxy resin

10 copies

multifunctional epoxy resin

10 copies

Thinner

3 copies

coupling agent

1 copy

Other additives

0.3 parts

paint

0.5 parts

Surfactant

0.1 part

Silica powder

600 copies

latent curing agent

5 copies

[0050] According to the above-mentioned component weight table, the preparation method is as follows,

[0051] 1. Add bisphenol F epoxy resin, multifunctional epoxy resin, diluent, pigment, surfactant, coupling agent, and stir at low speed for a certain period of time;

[0052] 2. Add silicon micropowder, raise the temperature to 55°C, stir at high speed and vacuumize, after stirring for 60 minutes, stop stirring, turn off the vacuum, and start to lower the temperature;

[0053] 3. After the temperature drops to 30°C, add latent curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com