Sound wave monitoring device and method for fluidized bed reactor

A fluidized bed reactor and sound wave technology, applied in chemical instruments and methods, measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve reactor safety hazards, affect fluidized bed flow field, improve, etc. problem, to achieve the effect of preventing reunion failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A fluidized bed reactor is used to react silica gel and quicklime inside the reactor, and the reaction is fully achieved by feeding gas. By using the device and method of this patent, the frequency range of the sound wave emitted by the internal reaction is measured in the range of 50-100kHz, and the degree of the reaction is judged by the energy fraction in this frequency range. Such as Figure 4 , which is the change curve of the energy fraction in the 50-100kHz frequency area with the growth of time.

Embodiment 2

[0054] The production conditions measured in the production of Qilu Linear Low Density Polyethylene Plant are as follows:

[0055] Superficial gas velocity: 0.6m / s

[0056] Pressure: 2.1MPa

[0057] Temperature: 91°C

[0058] Density: 0.3g / cm 3

[0059] Fluidized bed diameter: 3505mm

[0060] Static bed height: 11.5m

[0061] Melt index: 1.98g / (10min)

[0062] Particle size distribution: 10 mesh: 10.73%

[0063] 18 mesh: 42.63%

[0064] 35 mesh: 31.00%

[0065] 60 mesh: 10.73%

[0066] 120 mesh: 4.93%

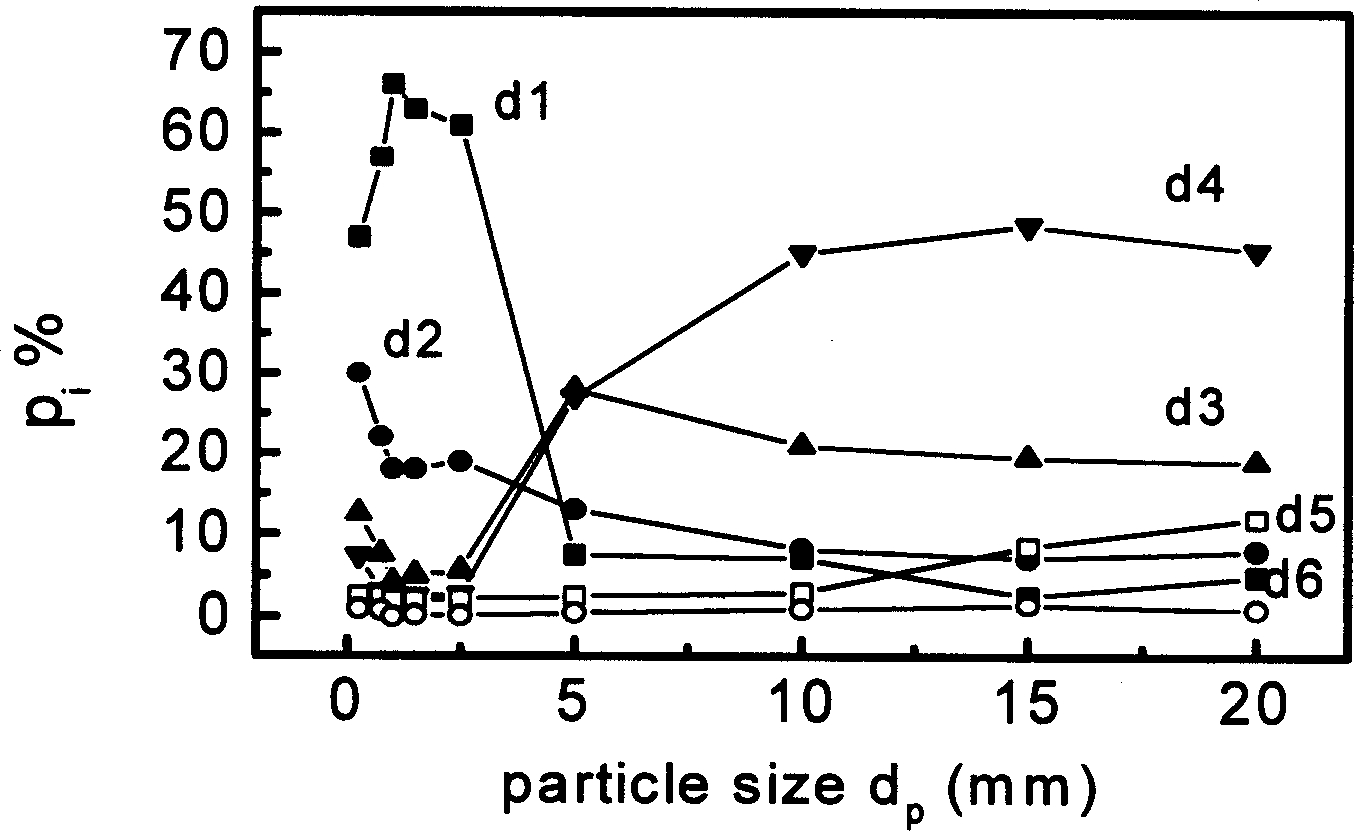

[0067] Use the device and method of the present invention to filter the external environment noise in the signal collected in the factory, as shown in Figure 5(a), and Figure 5(b) is the energy fraction diagram after wavelet packet analysis, using neural network analysis and decoupling analysis The obtained particle size distribution is as follows:

[0068]

Embodiment 3

[0070] The device and method of this patent are used in a laboratory-scale fluidized bed, and the experimental parameters are as follows:

[0071] Superficial gas velocity: 0.6m / s

[0072] Pressure: 0.1MPa

[0073] Temperature: 25°C

[0074] Density: 0.3g / cm 3

[0075] Fluidized bed diameter: 300mm

[0076] Static bed height: 0.35m

[0077] Melt index: 1.98g / (10min)

[0078] Polyethylene particle size distribution: 10 mesh: 10.73%

[0079] 18 mesh: 42.63%

[0080] 35 mesh: 31.00%

[0081] 60 mesh: 10.73%

[0082] 120 mesh: 4.93%

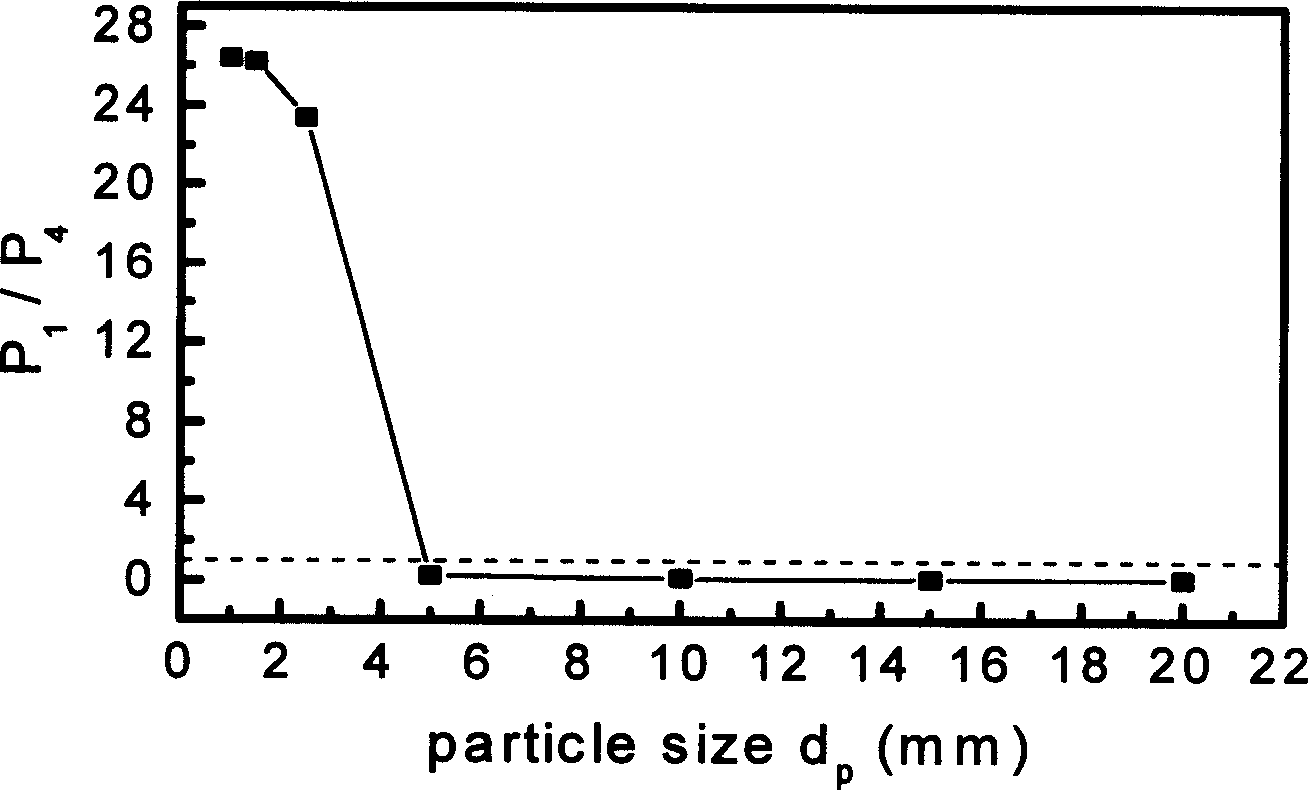

[0083] Joining agglomerate diameter: 20mm

[0084] Added agglomeration mass percentage: 1%

[0085] Using the analysis method of the present invention, there is an obvious peak at 3.91k-15.63kHz, and the size of the agglomerate is 21.2mm, and the percentage is 0.89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com