Method for on-line fault diagnosis of etching equipment

A technology for etching equipment and fault diagnosis, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as complexity, equipment maintenance sensitivity, and difficulty in application, to achieve sensitive fault monitoring, improve applicability, and avoid complexity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

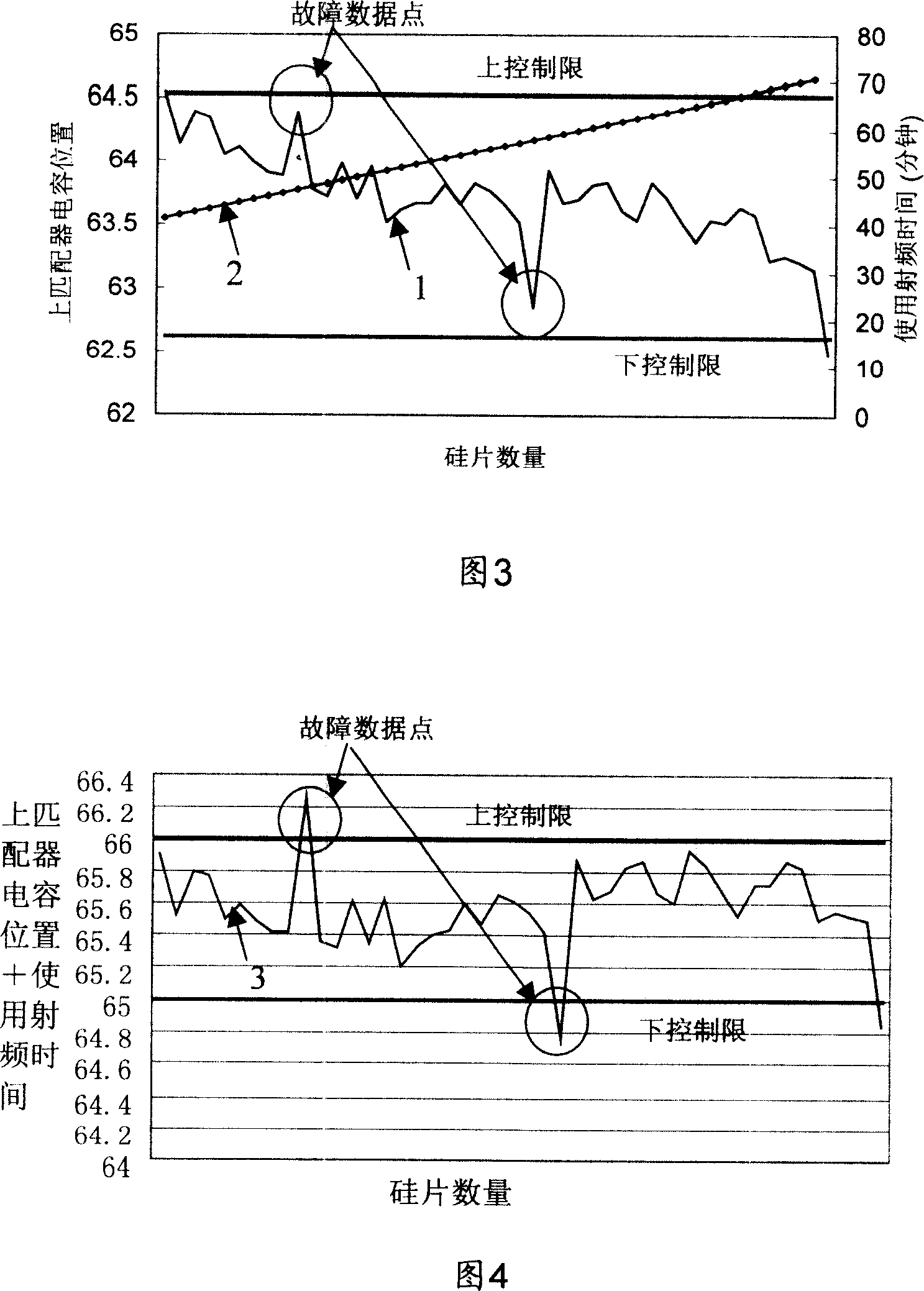

[0033] A preferred embodiment of the present invention is, firstly, select a plurality of parameters in the process, and perform mathematical operations on the multiple parameters in the process to obtain new parameters, the amount of change of the new parameters is more obvious than the amount of change of a single parameter ; Then, set the control limit as required, and judge the operating state of the etching equipment according to the new parameter and the control limit; if the new parameter value exceeds the control limit, it is judged that the etching equipment is in a fault state.

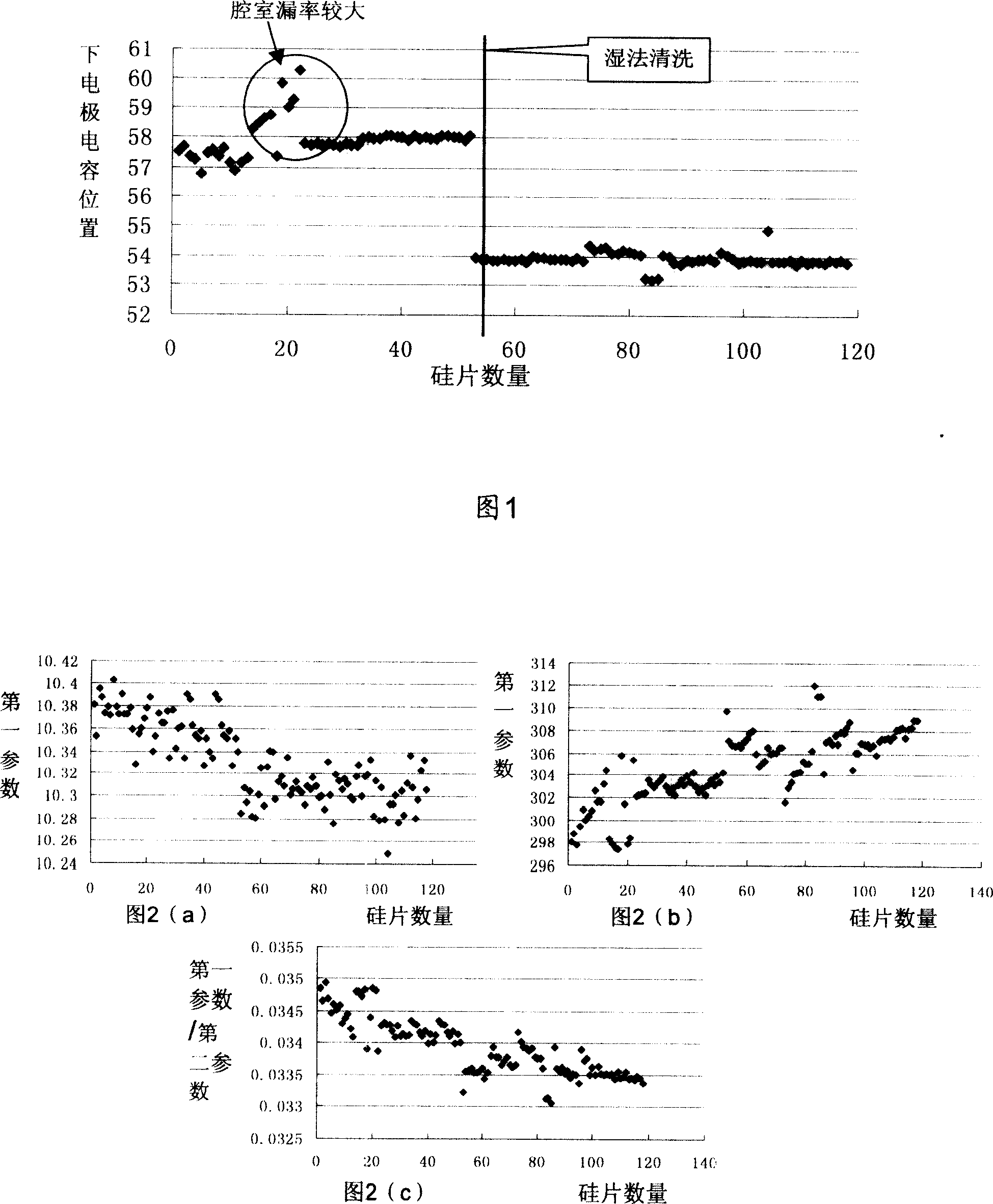

[0034] As shown in Figure 2 (a), 2 (b), and 2 (c), select the first parameter and the second parameter, wherein the first parameter decreases with the increase of the number of silicon wafers processed, assuming that this decrease is a fault state, It is necessary to increase its variation, so that the fault state can be detected early and processed to avoid scrapping of silicon wafers. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com