Touch screen, touch screen manufacturing method and display device

A touch screen and electrode technology, applied in the fields of display devices, touch screens and manufacturing methods thereof, can solve the problems of reducing the positioning sensitivity of touch points, reducing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention provide a touch screen, a manufacturing method thereof, and a display device, which are used to improve the sensitivity of touch point positioning on the touch screen and improve the touch effect of the touch screen.

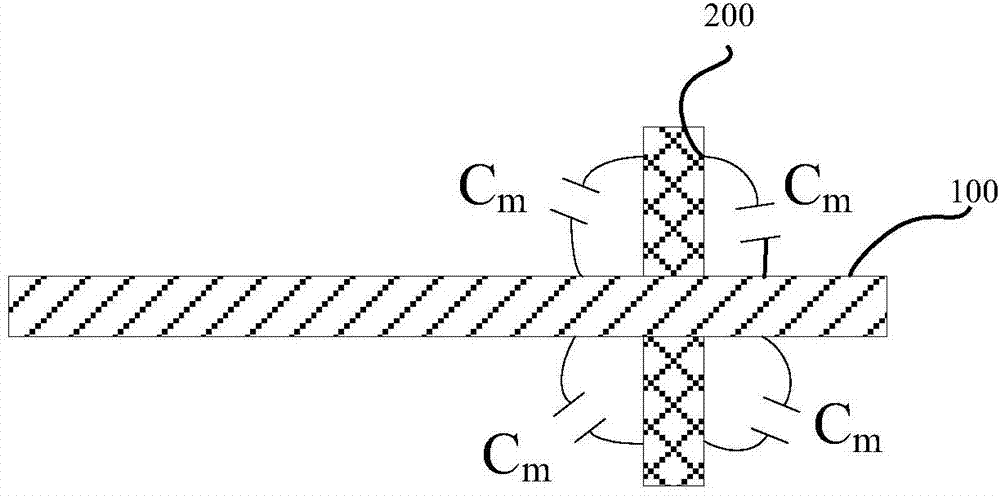

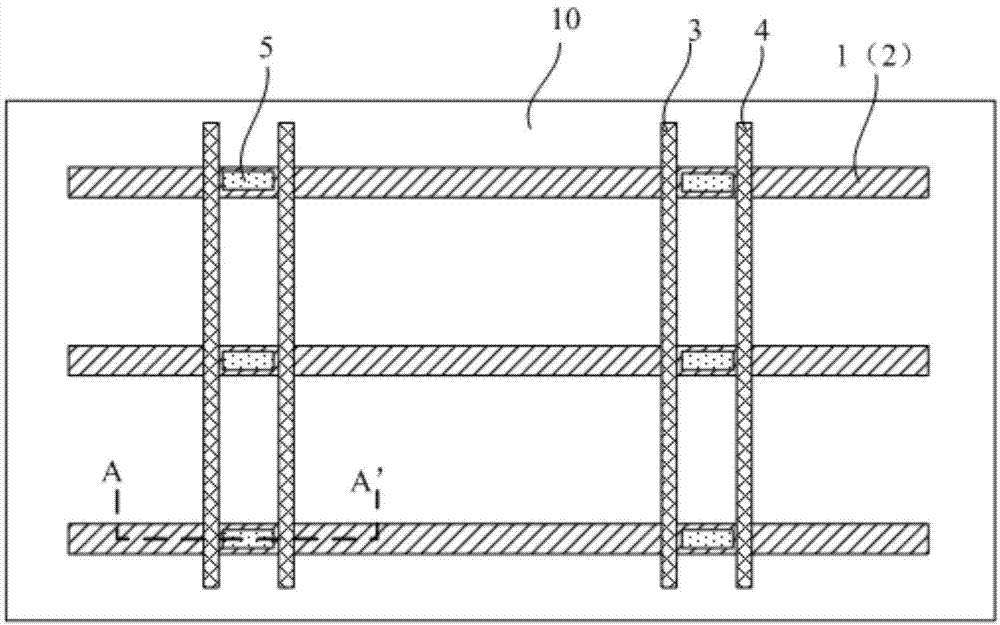

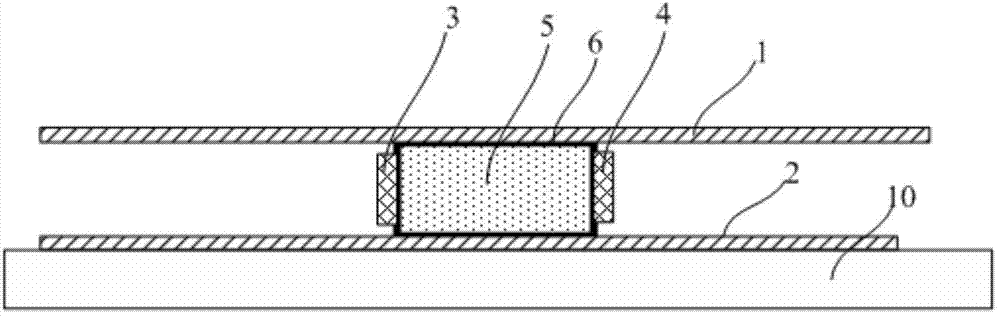

[0052] In the present invention, a plurality of first electrode groups distributed along a first direction are arranged on a base substrate, the first electrode group includes a first electrode and a second electrode, and a plurality of second electrode groups distributed along a second direction, the second The electrode group includes a third electrode and a fourth electrode, and the first direction and the second direction intersect. At the intersection of the first electrode group and the second electrode group, a hollow three-dimensional area is surrounded by the first electrode, the second electrode, the third electrode and the fourth electrode; the hollow three-dimensional area is provided with magnetic materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com