A detection method for fluid flow state in overflow pipe of multi-layer fluidized bed

A multi-layer fluidized bed and fluid flow technology, which is applied in the directions of measuring devices, geophysical measurements, and processing detection response signals, can solve problems such as signal distortion, difficult maintenance, and easy blockage of pressure monitoring, and achieve timely response, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

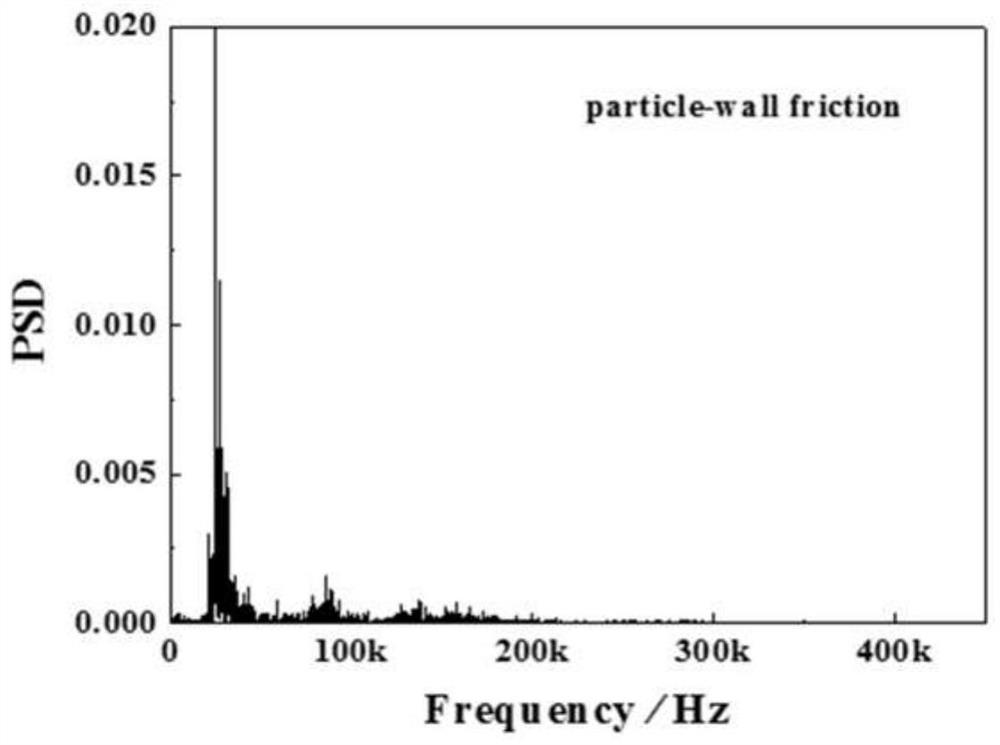

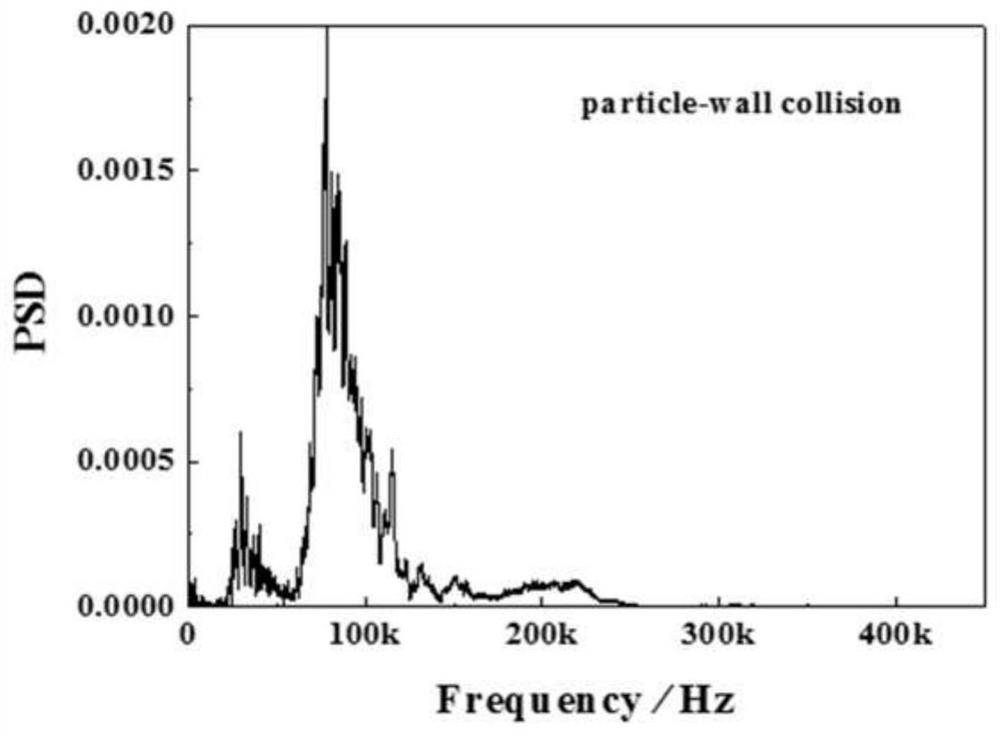

[0037] In a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, the distribution plate is a porous plate, the aperture is 2.0mm, and the porosity is 2.6%. Air is used as the fluidizing gas, and the average particle size is 613.7μm. Polypropylene granules were used as fluidized granules. The acoustic emission probe model used is AE144S, the passive acoustic emission transducer is attached to the overflow pipe of the distribution plate, and the sampling frequency is 900kHz. Using the db2 wavelet function, the collected signal is decomposed by 10-scale wavelet, and the spectrum structure of the signal is characterized by the distribution of wavelet energy fractions in each scale. In the power spectrum of the particle-wall friction signal, there is mainly a peak with a main frequency of 25 kHz, and in the PSD of the particle-wall impact signal, there is mainly a peak with a main frequency of 90 kHz. Change different air speeds and ob...

Embodiment example 2

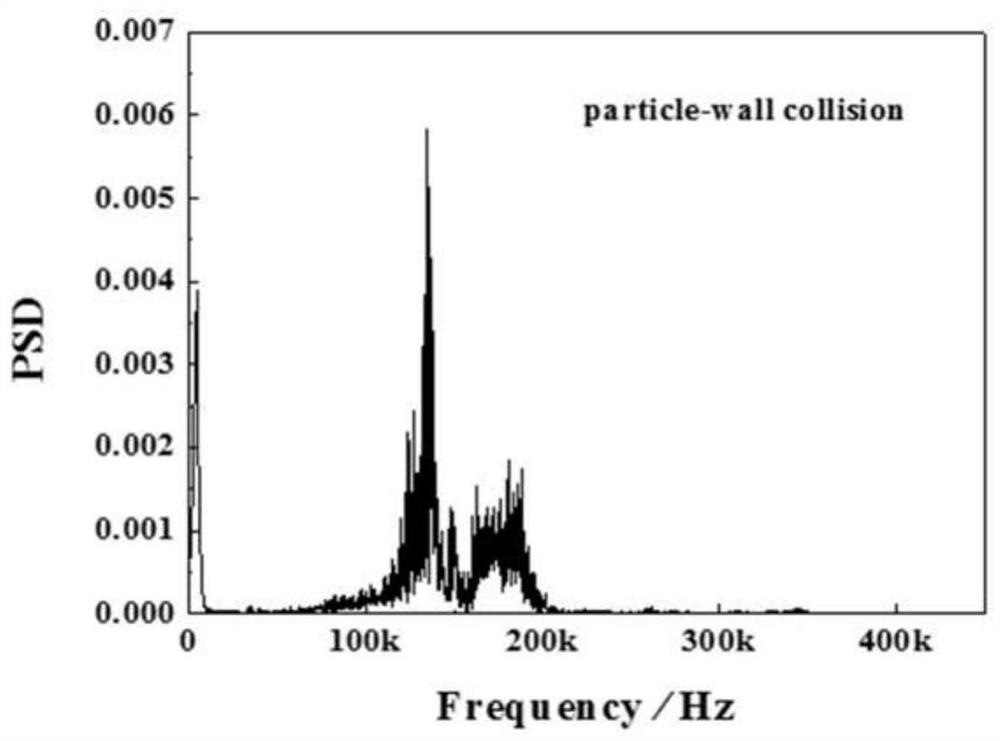

[0039] In a gas-solid fluidized bed made of plexiglass with a height of 1000mm and an inner diameter of 150mm, the distribution plate is a porous plate, the aperture is 2.0mm, and the porosity is 2.6%. Air is used as the fluidizing gas and the average particle size is 35.76μm. Pulverized coal particles are used as fluidized particles. The model of the acoustic emission probe used is PXR15, the passive acoustic emission transducer is attached to the overflow pipe of the distribution plate, and the sampling frequency is 600kHz. Change different air speeds and observe that the frequency in the acoustic signal is f collision =150-300kHz and f friction =18.75-37.5kHz energy fraction, to distinguish the feeding state of the fluidized bed overflow pipe. if D collision / D friction >3, indicating that the interaction between particles and the wall is dominant, the overflow pipe is not normally fed, and the power spectrum of the interaction between particles and the wall in the abno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com