Gypsum-based self-leveling mortar special for floor heating backfill

A self-leveling mortar, gypsum-based technology, applied in the field of building materials, can solve the problems of high cost, difficult preparation, difficult promotion, etc., and achieve the effects of low cost, short curing time and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

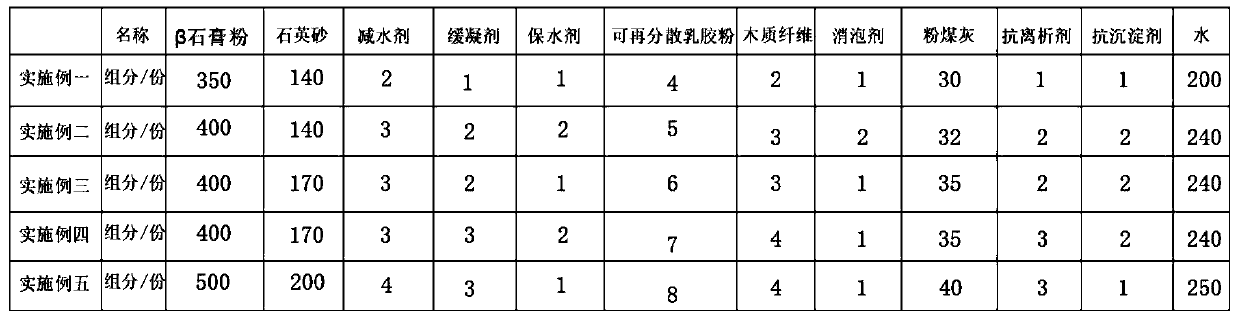

[0037] A special gypsum-based self-leveling mortar for floor heating backfill, including the following components by weight: 350 parts of β-gypsum powder, 140 parts of quartz sand, 2 parts of water reducer, 1 part of retarder, 1 part of water retention agent, recyclable 4 parts of dispersed latex powder, 2 parts of wood fiber, 1 part of defoamer, 30 parts of fly ash, 1 part of anti-sedimentation agent, 1 part of anti-segregation agent, and 200 parts of water.

[0038] Weigh 2kg sample according to the ratio, pour water into the mortar mixer, slowly pour in gypsum-based self-leveling powder, stir slowly for 1min, and then stir rapidly for 1min until uniform.

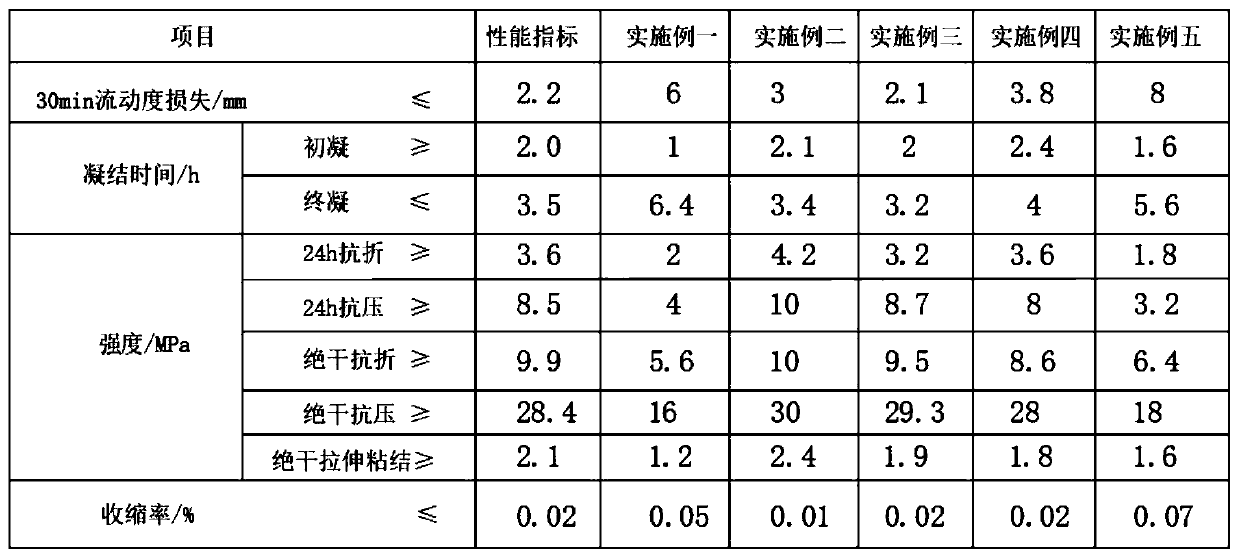

[0039] The performance of gypsum-based self-leveling mortar is tested according to the standard JC / T1023-2007 "Gypsum-based self-leveling sand general", the performance is as follows figure 2 .

Embodiment 2

[0041]A special gypsum-based self-leveling mortar for floor heating backfill, including the following components by weight: 400 parts of β gypsum powder, 170 parts of quartz sand, 3 parts of water reducer, 2 parts of retarder, 2 parts of water retention agent, recyclable 5 parts of dispersed latex powder, 3 parts of wood fiber, 2 parts of defoamer, 32 parts of fly ash, 2 parts of anti-sedimentation agent, 2 parts of anti-segregation agent, and 240 parts of water.

[0042] Weigh 2kg sample according to the ratio, pour water into the mortar mixer, slowly pour in gypsum-based self-leveling powder, stir slowly for 1min, and then stir rapidly for 1min until uniform.

[0043] The performance of gypsum-based self-leveling mortar is tested according to the standard JC / T1023-2007 "Gypsum-based self-leveling sand general", the performance is as follows figure 2 .

Embodiment 3

[0045] 400 parts of β gypsum powder, 170 parts of quartz sand, 3 parts of water reducer, 2 parts of retarder, 1 part of water retention agent, 6 parts of redispersible latex powder, 3 parts of wood fiber, 1 part of defoamer, fly ash 35 parts, 2 parts of anti-sedimentation agent, 1 part of anti-segregation agent, 240 parts of water.

[0046] Weigh 2kg sample according to the ratio, pour water into the mortar mixer, slowly pour in gypsum-based self-leveling powder, stir slowly for 1min, and then stir rapidly for 1min until uniform.

[0047] The performance of gypsum-based self-leveling mortar is tested according to the standard JC / T1023-2007 "Gypsum-based self-leveling sand general", the performance is as follows figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com