A waterborne polyurethane-acrylate copolymer emulsion and a preparing method thereof

A technology of polyurethane acrylate and copolymer emulsion, which is applied in the chemical industry, can solve the problems of poor compatibility stability, limited flame retardancy, and low solid content, and achieve good flame retardancy and improve heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

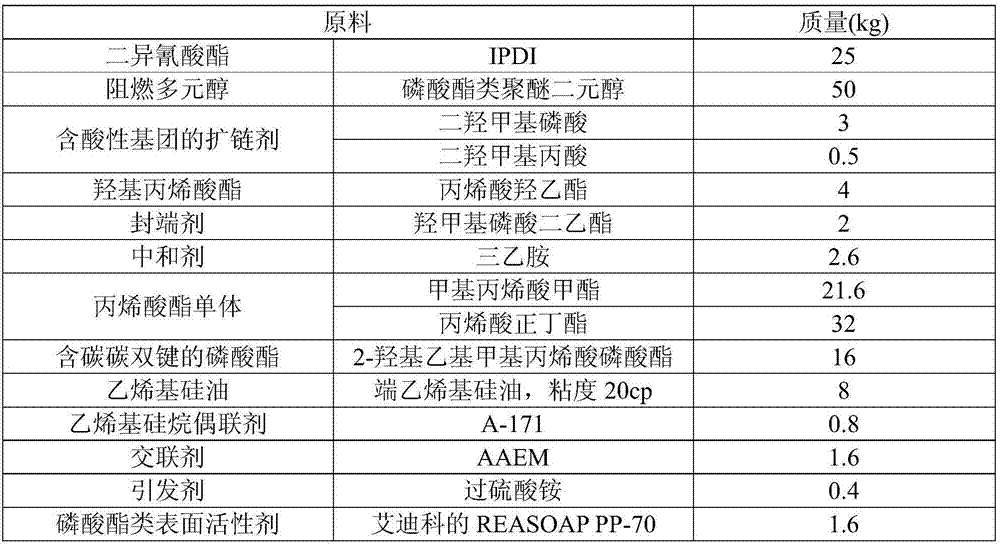

[0072] A waterborne polyurethane acrylate copolymer emulsion, which is prepared with the following raw materials:

[0073]

[0074] The preparation method of the above-mentioned aqueous polyurethane acrylate copolymer emulsion includes the following steps:

[0075] (1) Dry the flame-retardant polyol in vacuum at 120°C for 2h, mix it with diisocyanate according to the formula, react at 90°C for 2h, then add a formula amount of chain extender containing acidic groups, and react at 75°C for 1.5 h, obtain polyurethane prepolymer I;

[0076] (2) Reacting the above-mentioned polyurethane prepolymer I with the formulated amount of hydroxy acrylate at 75°C for 45 minutes, then adding the formulated amount of end-capping agent, and reacting at 60°C for 60 minutes to obtain polyurethane prepolymer II;

[0077] (3) Cooling the temperature of the above-mentioned polyurethane prepolymer II to below 40°C, adding a formula amount of neutralizer, neutralizing reaction for 10 minutes, and then adding ...

Embodiment 2

[0081] A waterborne polyurethane acrylate copolymer emulsion, which is prepared with the following raw materials:

[0082]

[0083]

[0084] The preparation method of the above-mentioned aqueous polyurethane acrylate copolymer emulsion includes the following steps:

[0085] (1) The flame-retardant polyol was vacuum dried at 120℃ for 2h, mixed with diisocyanate according to the formula, reacted at 80℃ for 3h, and then added the formula amount of chain extender containing acidic groups, reacted at 60℃ for 3h , Obtain polyurethane prepolymer I;

[0086] (2) The above-mentioned polyurethane prepolymer I is reacted with the formulated amount of hydroxy acrylate at 90°C for 30 minutes, and then the formulated amount of end-capping agent is added, and reacted at 80°C for 30 minutes to obtain polyurethane prepolymer II;

[0087] (3) Cool the above-mentioned polyurethane prepolymer II to below 40°C, add a formula amount of neutralizer, neutralize for 20 minutes, then add a formula amount of ac...

Embodiment 3

[0091] A waterborne polyurethane acrylate copolymer emulsion, which is prepared with the following raw materials:

[0092]

[0093]

[0094] The preparation method of the above-mentioned aqueous polyurethane acrylate copolymer emulsion includes the following steps:

[0095] (1) The flame-retardant polyol was vacuum dried at 120℃ for 2h, mixed with diisocyanate according to the formula, reacted at 70℃ for 4h, then added the formula amount of chain extender containing acidic groups, and reacted at 90℃ for 1.5 h, obtain polyurethane prepolymer I;

[0096] (2) The above-mentioned polyurethane prepolymer I was reacted with the formulated amount of hydroxy acrylate at 60°C for 60 minutes, and then the formulated amount of end-capping agent was added, and reacted at 70°C for 45 minutes to obtain polyurethane prepolymer II;

[0097] (3) Cooling the temperature of the above-mentioned polyurethane prepolymer II to below 40°C, adding a formula amount of neutralizer, neutralizing reaction for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com