Heat-resistant concrete and preparation method thereof

A technology of heat-resistant concrete and water reducing agent, applied in the field of concrete, can solve the problems of low crushing index of water slag, reduced early strength of concrete, poor workability of water slag and cement, etc., so as to reduce production cost, improve product quality, Increase the effect of retarding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

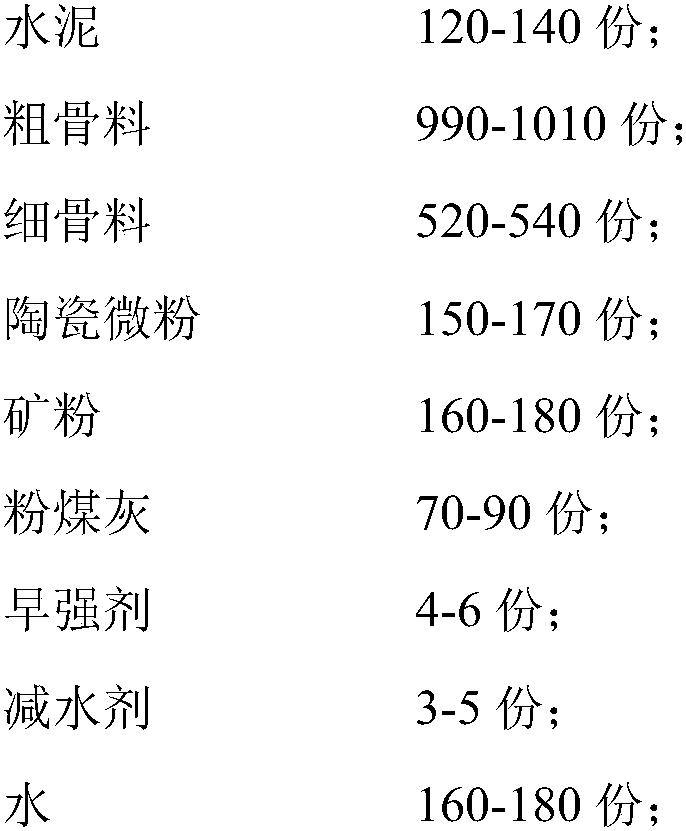

Method used

Image

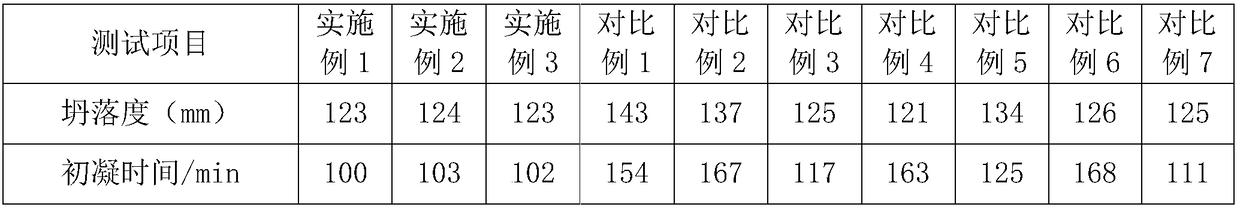

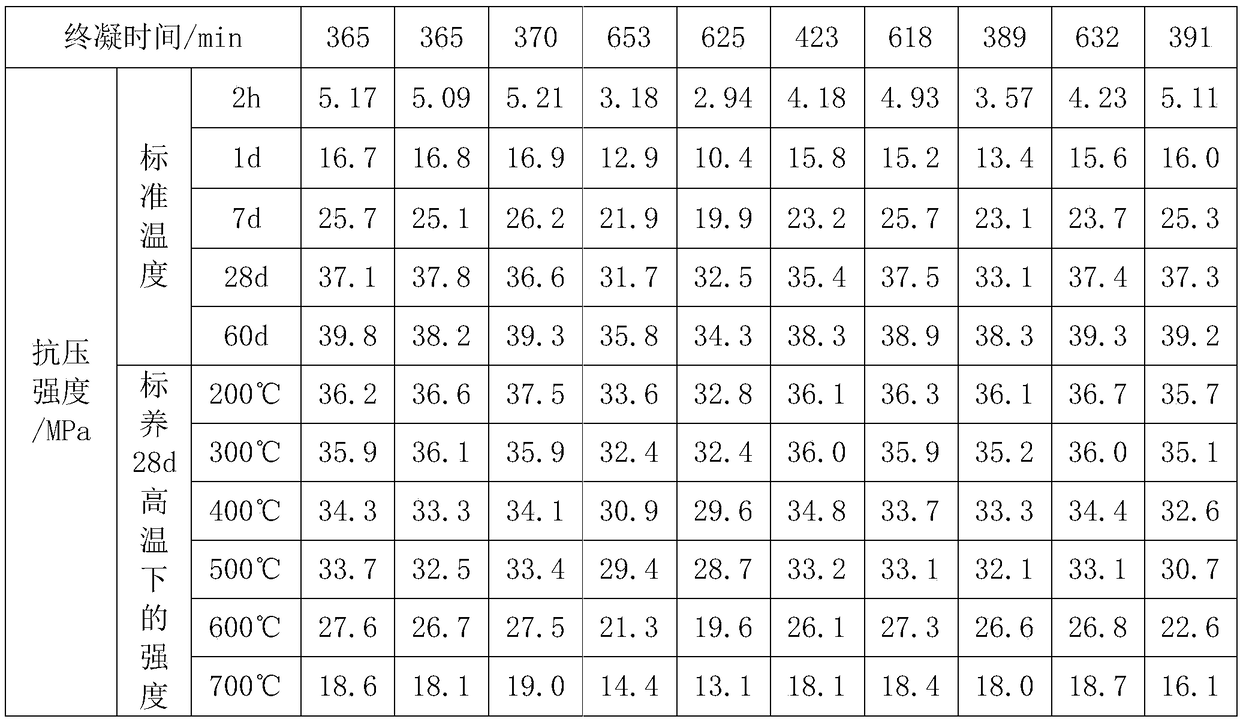

Examples

Embodiment 1

[0051] Embodiment 1: A kind of heat-resistant concrete is prepared by the following method:

[0052] S1: Soak the slag fine aggregate in water for 30 hours at a temperature of 21°C;

[0053] S2: 130kg cement, 980.4kg basalt crushed stone, 19.6kg barite crushed stone, 530kg water slag, 160kg ceramic powder, 170kg mineral powder, 80kg fly ash, 2.5kg calcium formate, 2.5kg sodium silicate, 4kg early Strong polycarboxylate water reducer and 170kg of water are mixed and stirred evenly to obtain a mixture;

[0054] S3: The mixture is poured into the mold, and cured naturally for 15 hours to obtain heat-resistant concrete.

[0055] Among them, the cement is ordinary Portland cement of P.O.42.5; the particle size of the basalt crushed stone is 5-10mm continuous gradation, and the apparent density of the crushed stone is 2830kg / m 3 , the loose bulk porosity is 45%, and the loose bulk density is 1560kg / m 3 ; Barite particle size is 5-10mm continuous gradation, apparent density is 435...

Embodiment 2

[0056] Embodiment 2: A kind of heat-resistant concrete is prepared by the following method:

[0057] S1: Soak the slag fine aggregate in water for 36 hours at a temperature of 20°C;

[0058] S2: 120kg cement, 970.6kg basalt crushed stone, 19.4kg barite crushed stone, 530kg water slag, 150kg ceramic powder, 170kg mineral powder, 80kg fly ash, 2kg calcium formate, 2kg sodium silicate, 4kg early strength type Polycarboxylate water-reducer and 170kg of water are mixed and stirred evenly to obtain a mixture;

[0059] S3: Pour the mixture into the mold, and let it be naturally cured for 10 hours to obtain heat-resistant concrete.

[0060] Among them, the cement is ordinary Portland cement of P.O.42.5; the particle size of the basalt crushed stone is 5-10mm continuous gradation, and the apparent density of the crushed stone is 2830kg / m 3 , the loose bulk porosity is 45%, and the loose bulk density is 1560kg / m 3 ; Barite particle size is 5-10mm continuous gradation, apparent densit...

Embodiment 3

[0061] Embodiment 3: A kind of heat-resistant concrete is prepared by the following method:

[0062] S1: Soak the slag fine aggregate in water for 24 hours at a temperature of 22°C;

[0063] S2: 140kg cement, 990.2kg basalt crushed stone, 19.8kg barite crushed stone, 540kg water slag, 170kg ceramic powder, 180kg mineral powder, 90kg fly ash, 3kg calcium formate, 3kg sodium silicate, 5kg early strength type Polycarboxylate water-reducer and 180kg of water are mixed and stirred evenly to obtain a mixture;

[0064] S3: Pour the mixture into the mold, and let it be naturally cured for 20 hours to obtain heat-resistant concrete.

[0065] Among them, the cement is ordinary Portland cement of P.O.42.5; the particle size of the basalt crushed stone is 5-10mm continuous gradation, and the apparent density of the crushed stone is 2830kg / m 3 , the loose bulk porosity is 45%, and the loose bulk density is 1560kg / m 3 ; Barite particle size is 5-10mm continuous gradation, apparent densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com