Preparation method and application of gypsum retarder

A gypsum retarder and a technology of retarder, which are applied in the field of preparation of gypsum retarder, can solve the problems of unsatisfactory strength loss of gypsum products, and achieve the effects of reducing strength loss and water demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a gypsum retarder, wherein the gypsum retarder is prepared from a diacid or acid anhydride substance and an ammonia-containing substance, and the molar ratio of the diacid or acid anhydride:ammonia-containing substance is 1:1~ 1:1.5; the diacid or acid anhydride substances include maleic anhydride or maleic acid or fumaric acid; the ammonia-containing substances include ammonium carbonate or ammonium bicarbonate or ammonia water;

[0050] The specific steps of the preparation method are:

[0051] The first step: prepare the intermediate product of gypsum retarder

[0052]React diacid or acid anhydride:ammonia-containing substances at a molar ratio of 1:1~1:1.5 at a temperature of 50~80°C for 1~2 hours, then raise the temperature to 150~190°C for 10~60min, cool to At room temperature, an intermediate product is formed;

[0053] Step 2: Prepare gypsum retarder

[0054] a. Preparation of the retarder aqueous solution: take the intermediate product...

Embodiment 2

[0065] A kind of preparation method of gypsum retarder, described gypsum retarder is prepared from L-aspartic acid, and the concrete steps of described preparation method are:

[0066] The first step: prepare the intermediate product of gypsum retarder

[0067] a1. Direct thermal shrinkage and polymerization of L-aspartic acid at a temperature of 150-250°C to form an intermediate product;

[0068] a2. Dissolve L-aspartic acid in a solvent to form an L-aspartic acid solution with a concentration of 10-50%, add a catalyst to the L-aspartic acid solution, and react at a temperature of 130-180°C 10 to 60 minutes, then cooled to room temperature, adding ethanol to the solution to form a precipitate, standing and filtering to obtain the intermediate product;

[0069] Wherein: the catalyzer is phosphoric acid, hydrochloric acid, sulfuric acid, and the mol ratio of catalyzer: L-aspartic acid is 0.05~0.3:1;

[0070] The solvent is sulfolane, dimethyl sulfolane, propylene carbonate, b...

Embodiment 3

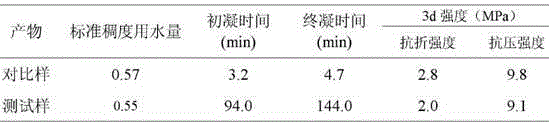

[0089] A kind of application of the gypsum retarder obtained by the preparation method described in embodiment 1 and embodiment 2, the content in embodiment 1 and embodiment 2 content should also be the content of this embodiment, wherein,

[0090] The setting retarder obtained by the preparation method described in Example 1 and Example 2 is added to the gypsum to prolong the setting time of the gypsum and reduce the loss of strength of the gypsum hardened body. 0.5%, the retarder is calculated on dry matter.

[0091] The retarder used in the application has a weight average molecular weight in the range of 2000-30000, preferably 3500-10000, more preferably 4000-9000.

[0092] In an embodiment, the retarder can be used in the form of an aqueous solution or a fine powder, and the preferred concentration range of the aqueous solution is 10% to 50%, more preferably 30% to 40%.

[0093] The amount of retarder used in gypsum retarder is calculated by weight percentage, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com