Admixture prepared from gypsum activation steel slag and ore powder and high-performance concrete prepared from admixture

A technology of high-performance concrete and admixtures, applied in the direction of cement production, etc., to achieve the effect of improving the effect, cheap raw materials, improving early strength and later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of embodiment 1 admixture

[0025] The preparation process of the admixture: After mechanically grinding the converter steel slag of Shaoguan Iron and Steel Co., Ltd., the specific surface area is 500-700m 2 / kg steel slag powder; S95 grade granulated blast furnace slag powder provided by Shaogang Iron and Steel Group Co., Ltd., with a density of 2.83g / cm 3 , with a specific surface area of 413m 2 / kg; gypsum purchased on the market; mix the three at a mass ratio of 9:21:2 to obtain an admixture, denoted as GF. The chemical compositions of steel slag and slag are shown in Table 1 and Table 2 below, respectively.

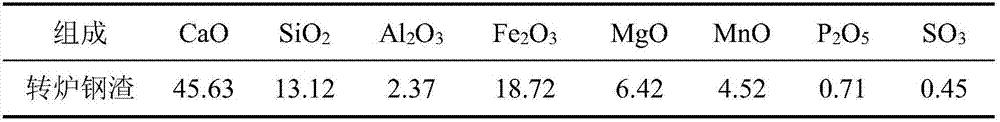

[0026] Table 1 Steel slag chemical composition (%)

[0027]

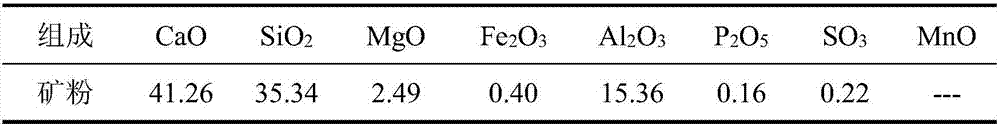

[0028] Table 2 Mineral Powder Chemical Composition (%)

[0029]

Embodiment 2

[0030] The preparation of embodiment 2 concrete

[0031] The GF prepared in Example 1 is used to prepare high-performance concrete, and the cement used for preparing the concrete is P.II42.5R cement produced by Guangzhou Zhujiang Cement Co., Ltd.; the crushed stone is the crushed stone provided by Guangzhou Ande Construction Components Co., Ltd., The place of origin is Zengcheng Yonghe, and the rock type is granite; the water reducer is the polycarboxylate high-performance water reducer HPC-R provided by Guangzhou Ande Construction Components Co., Ltd., and the water reducer is light brown liquid.

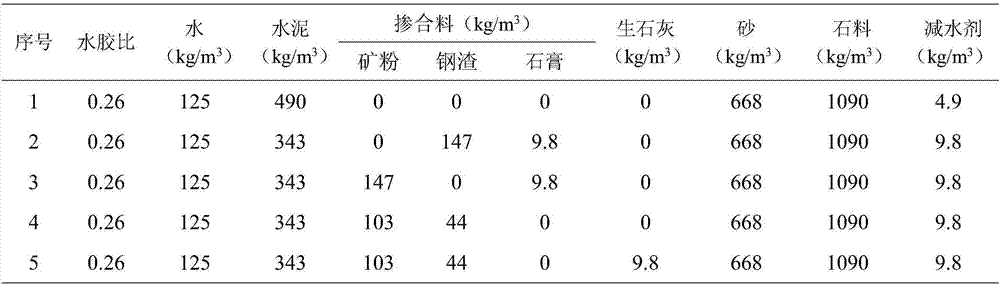

[0032] The raw materials and dosage used in concrete preparation are shown in Table 3. In the preparation process of the 10 groups of concrete, except for the cementitious material, the dosage of other raw materials and the preparation method are consistent. The admixture in the cementitious material is 30% of the total cementitious material instead of cement, and is mixed with net...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com