Waste brick superfine regenerated active micro-powder and preparation method thereof

A technology of active micropowder and waste brick powder, which is applied in the field of building materials, can solve the problems of unusable, waste bricks with many pores, and unsuitable recycled aggregates, etc., and achieve the effects of reducing cement consumption, high-efficiency activation, and remarkable modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The waste bricks are dried and broken into particles of 0-3 mm, ground for 15-30 minutes, and a composite activator is added and fully mixed to prepare the waste brick superfine regenerated active micropowder. The dosage of the composite activator is 2% of the mass of the waste brick powder, and the contents of quicklime, hemihydrate desulfurized gypsum and dihydrate desulfurized gypsum are respectively 25wt%, 50wt% and 25wt%.

[0015] The specific surface area of the waste brick ultrafine regenerated active micropowder thus prepared reaches 610m 2 / kg, the median diameter D50 of the particle size distribution is 14 μm, and the D90 is 31 μm.

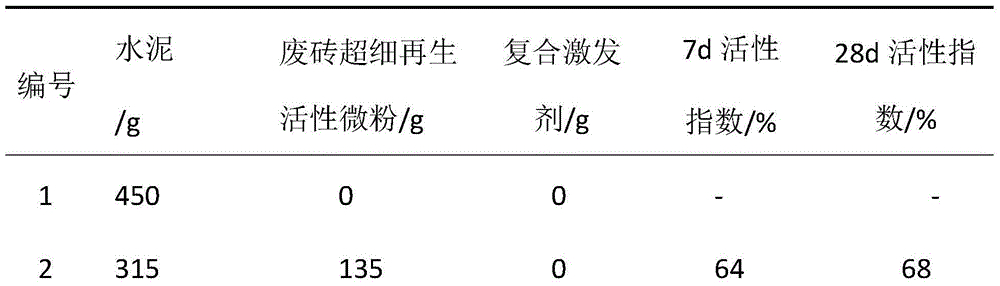

[0016] The superfine regenerated active micropowder of waste bricks is mixed into cement mortar as a concrete admixture (30%), and the concrete admixture is determined with reference to GB / T 1596-2005 "Fly Ash Used in Cement and Concrete". Compound Activity Index. Table 1 is the comparison of the activity index of the concrete...

Embodiment 2

[0021] The waste bricks are dried and broken into particles of 0-3 mm, ground for 15-30 minutes, and a composite activator is added and fully mixed to prepare the waste brick superfine regenerated active micropowder. The dosage of the composite activator is 2.5% of the mass of the waste brick powder, and the contents of quicklime, hemihydrate desulfurized gypsum and dihydrate desulfurized gypsum are respectively 40wt%, 20wt% and 40wt%.

[0022] The specific surface area of the waste brick ultrafine regenerated active micropowder thus prepared reaches 605m 2 / kg, the median diameter D50 of the particle size distribution is 19 μm, and the D90 is 40 μm.

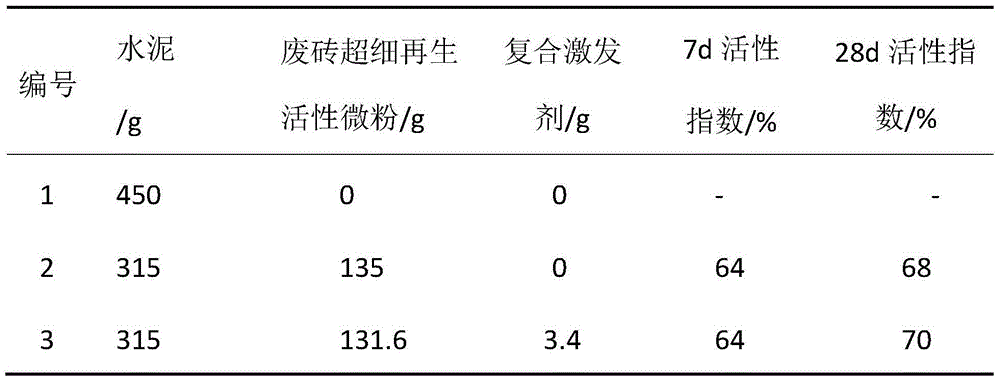

[0023] The superfine regenerated active micropowder of waste bricks is mixed into cement mortar as a concrete admixture (30%), and the concrete admixture is determined with reference to GB / T 1596-2005 "Fly Ash Used in Cement and Concrete". Compound Activity Index. Table 2 is the comparison of the activity index of the concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com