Method for quantitatively evaluating activity of tuyere convolute region

A technology for quantitative evaluation and swirl area, applied in directions such as tuyeres, can solve problems such as the mismatch between the kinetic energy of the blast and the shape characteristics of the swirl area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

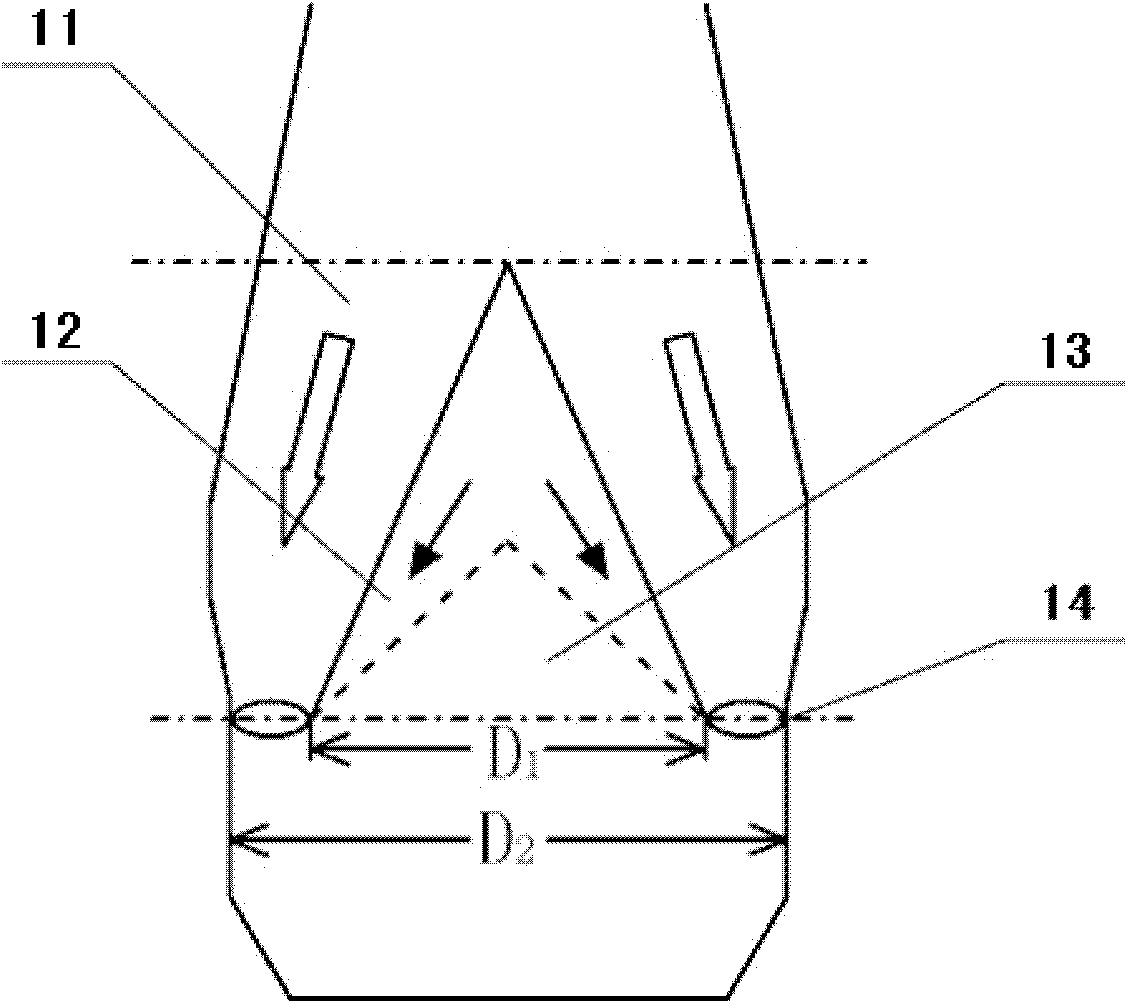

[0063] Such as figure 1 As shown, the coke below the entire reflow zone of the blast furnace can be divided into three areas: the main coke area 11 feeding to the gyration area, the coke slow-moving area 12 and the dead charge column 13 . Among them, D 1 is the diameter of the bottom surface of the dead material column 13 at the tuyere swirl zone 14, D 2 is the hearth diameter, therefore, (D 2 -D 1 ) / 2 is the depth D of the maneuver area R , the larger the value, the larger the corresponding coke mainstream area 11, and the smaller the dead material column 13, the air-permeable and liquid-permeable passages gradually increase, which is beneficial to the forward movement of the charge, the uniform distribution of the gas flow, and the relationship between the gas and the charge. The heat transfer and mass transfer process between them.

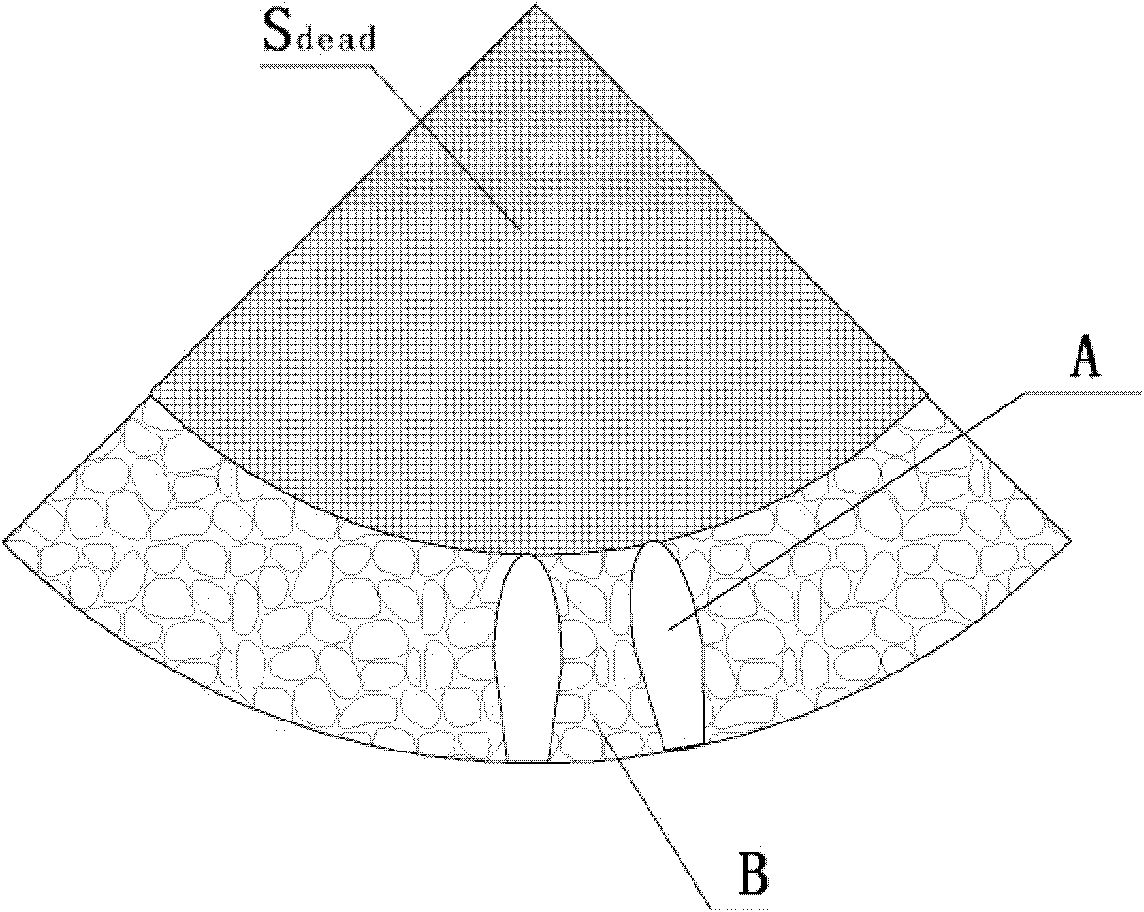

[0064] Such as figure 2 shown, for figure 1 Schematic cross-sectional view at the horizontal plane of the mid-tuyere. The top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com