Method for preparing inorganic slag fibers by using thermal state coal slag

A technology of slag fiber and coal slag, which is applied in the direction of glass manufacturing equipment and manufacturing tools, can solve the problems of insufficient dual utilization of resources and waste heat energy, and achieve full utilization of waste energy, simple and easy preparation method, and improved The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

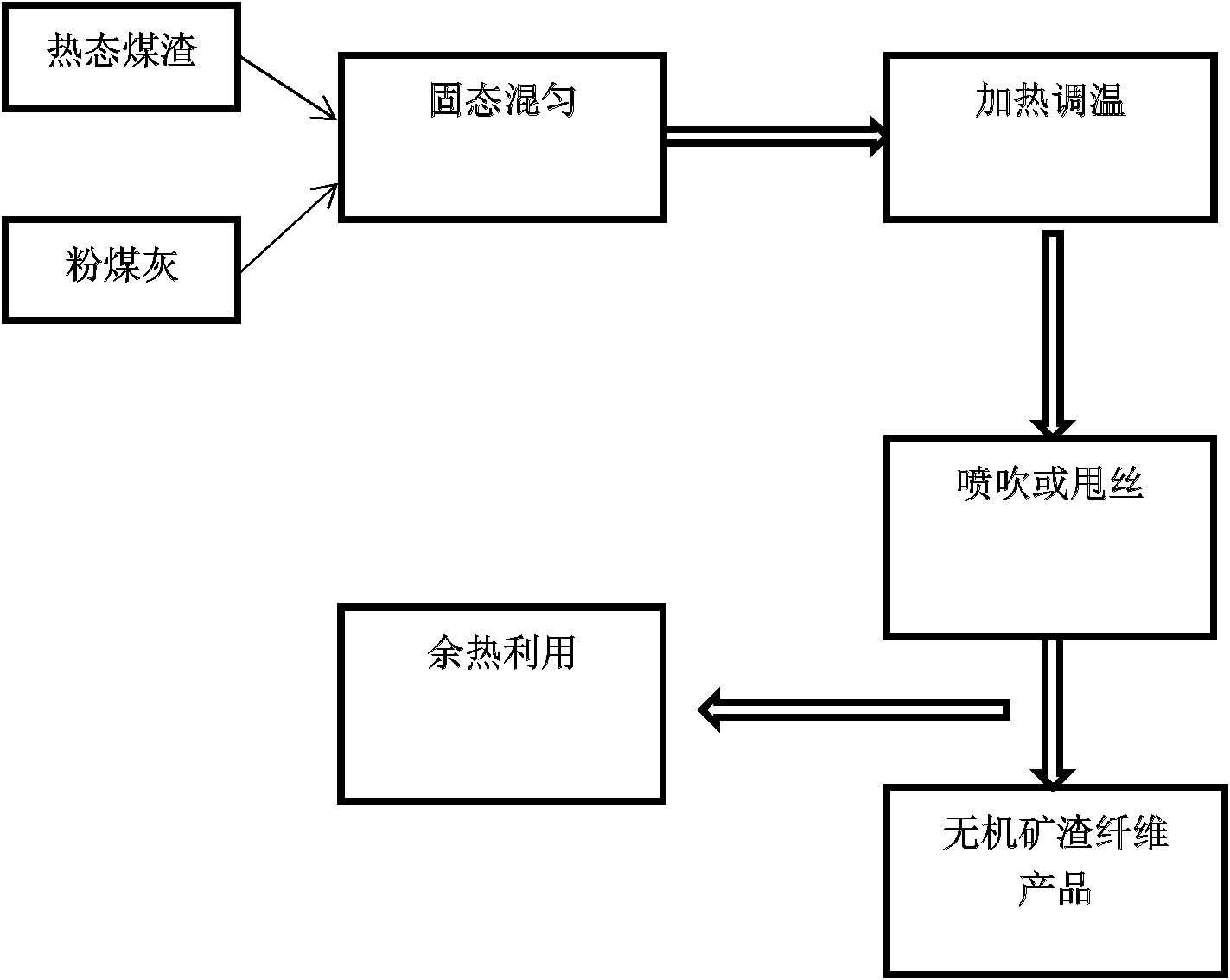

[0038] The preparation method flow process of following embodiment is as description in accompanying drawing figure 1 shown. The hot coal slag used is: one or a mixture of waste slag discharged from coal combustion in thermal power plants, industrial and civil boilers, and other equipment. The main components include: SiO 2 40-50%, Al 2 o 3 20-35%, Fe 2 o 3 4-20%, CaO 1-5%, and a small amount of magnesium, sulfur, carbon, etc. The temperature of hot cinder is 900-1100°C.

[0039] The fly ash used includes: coal-fired power plants, boilers, etc., fly ash produced during coal combustion, solid residue, waste or their mixture. The element composition includes: O 40-47%, Si 10-30%, Al 6-24%, Fe 1-20% and Ca 0-25%.

Embodiment 1

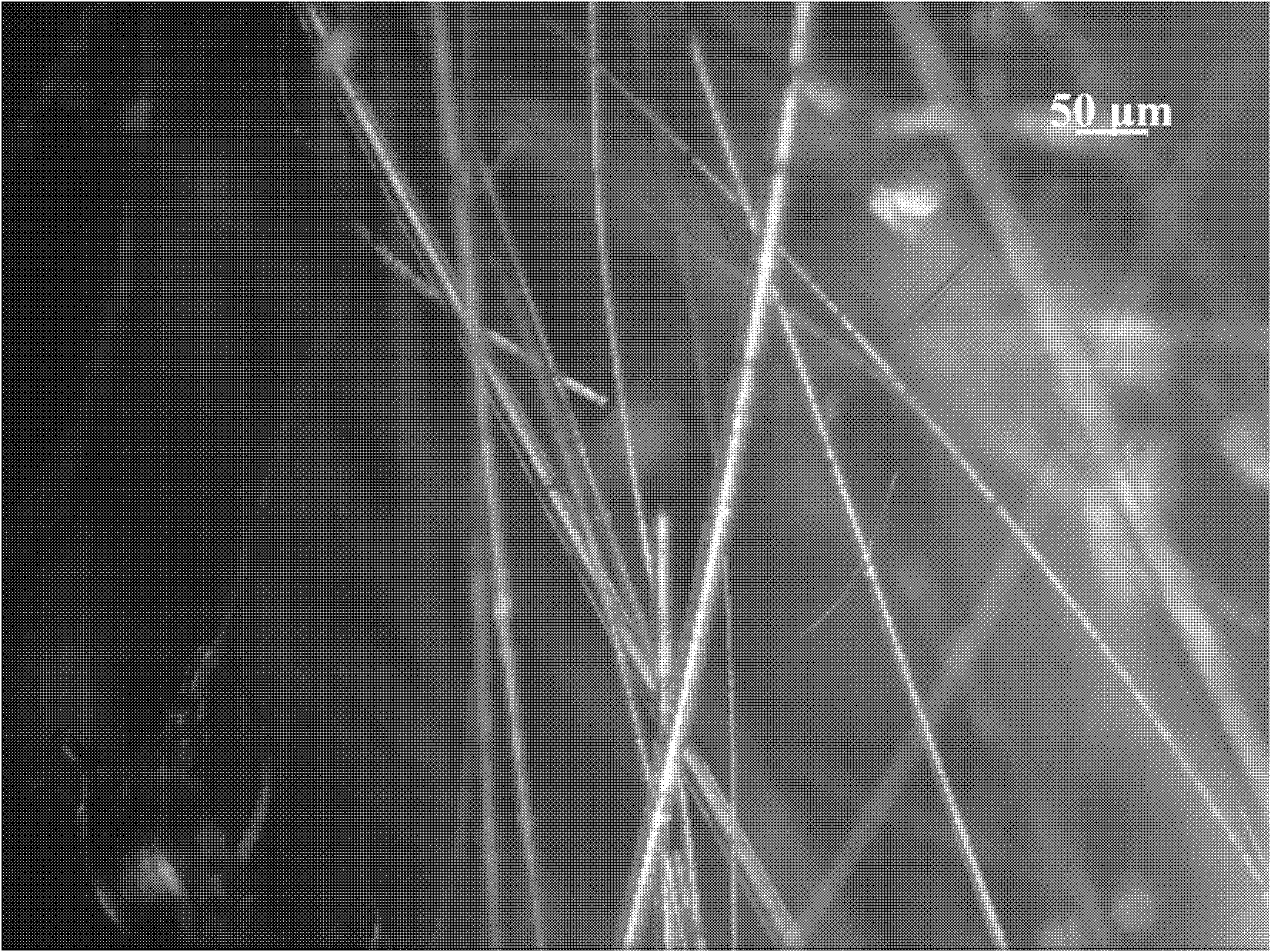

[0041]70% by weight of hot coal slag and 30% of fly ash are solid-state mixed in a mixing device. After mechanical mixing, they are added to a melting resistance furnace with a temperature of 1600 ° C. After they are completely melted, the molten liquid It flows into the spinning machine, and under the action of the centrifugal force of the spinning roller, inorganic slag fibers are obtained, and at the same time, the fibers are cooled by blowing compressed air. The appearance of the fibers under the microscope is as follows: figure 2 shown. The average fiber diameter is 6.4μm, and the tensile strength of single filament is 65MPa.

Embodiment 2

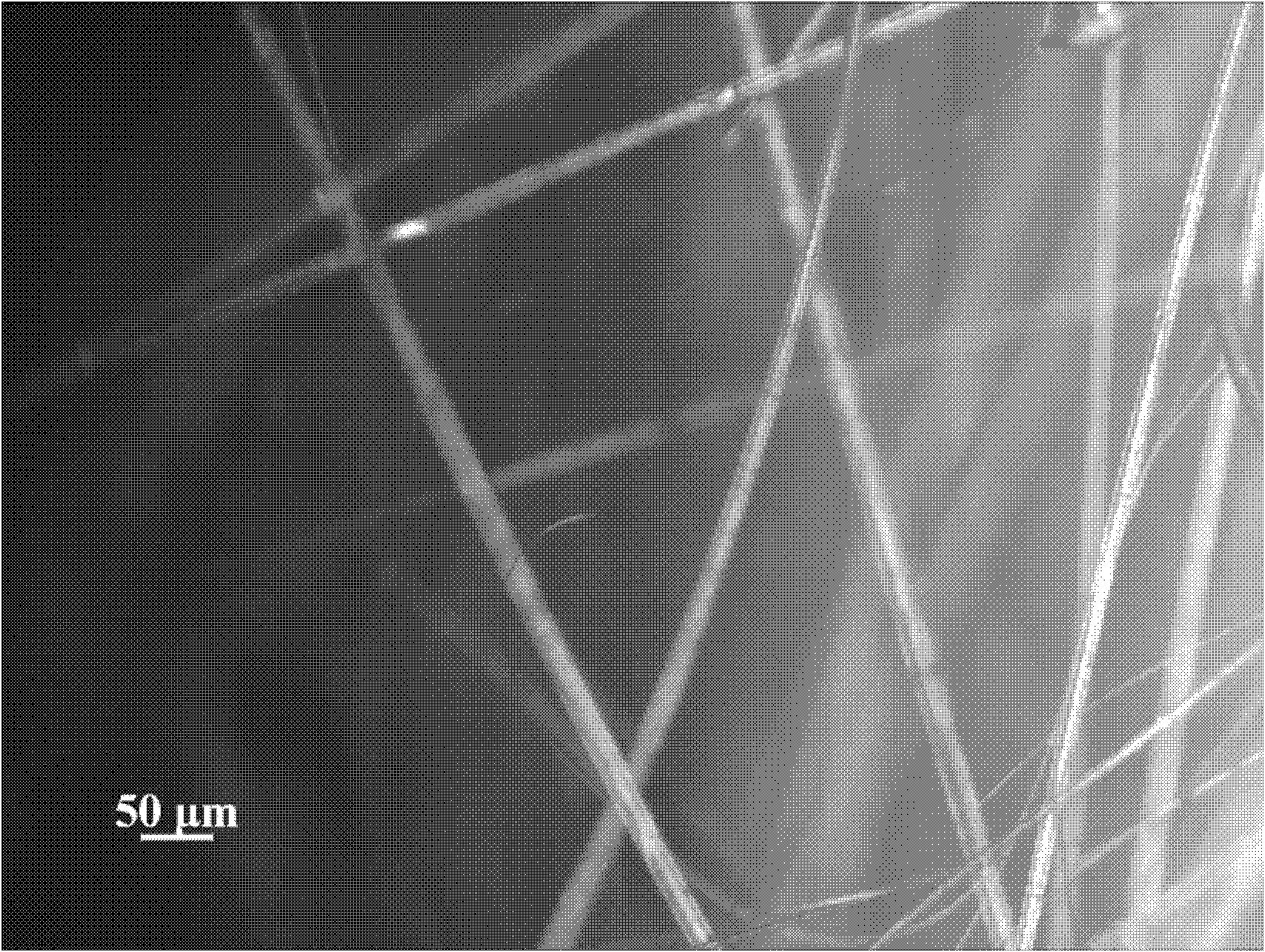

[0043] Adopt the same preparation method as Example 1, the difference is that the percentage by weight of hot coal slag in the mixture is 50%, and the morphology of the inorganic slag fibers obtained at last is as follows: image 3 shown. The average fiber diameter is 5.6μm, and the tensile strength of single filament is 75MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Monofilament tensile strength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com