Method for treating low air permeability coal seam gas discharge

A coal seam gas and gas permeability technology, which is applied in the field of dealing with low gas permeability coal seam gas emissions, can solve problems such as disaster accidents, large engineering quantities, and hidden safety hazards, and achieve the effects of easy operation, low cost and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

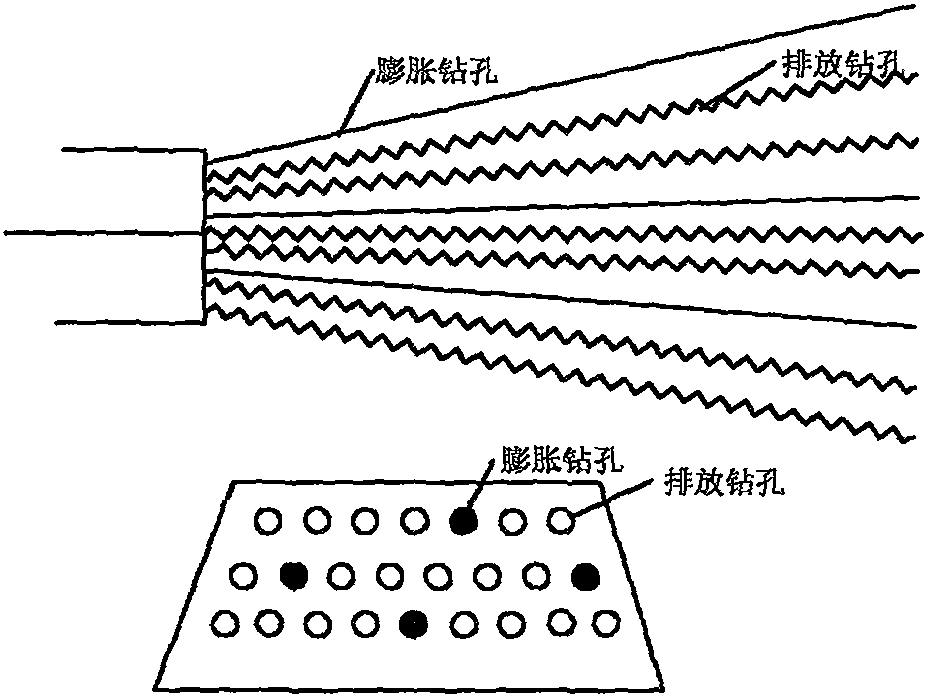

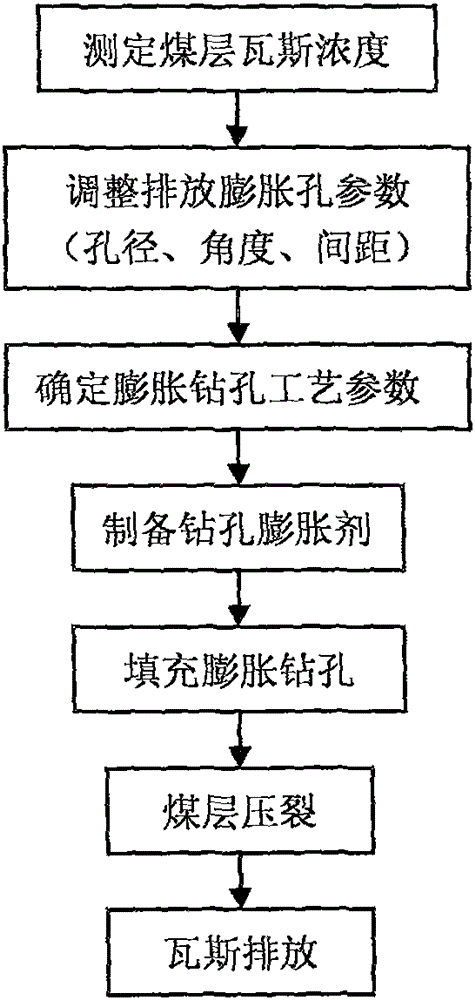

[0014] The specific embodiment of the gas discharge method in the coal seam of the present invention includes drilling the coal seam in the coal mining face, using a drilling expansion agent to perform coal seam fracturing, increasing the gas permeability of the coal seam, and discharging gas.

[0015] When statically fracturing rock formations with drilling expansion agents, firstly arrange broken holes on the coal seam according to the free surface and hardness of the coal seam;

[0016] Then select the drilling expansion agent and prepare it according to the characteristics of the drilling expansion agent;

[0017] Afterwards, the prepared drilling expansion agent is poured into the drilling hole, and the coal seam is broken after the drilling expansion agent reacts.

[0018] After the coal seam is broken, the gas can be discharged through free diffusion or negative pressure equipment.

[0019] Specifically, when arranging expansion drills, it is best to follow the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com