Wind pressure air drilling equipment in downhole soft outbursting coal bed and process matched therewith

A technology for protruding coal seam and wind pressure, applied in the field of wind pressure air drilling equipment and supporting technology, can solve the problems of limited application of bedding holes, poor stability of coal seam, and high gas content, so as to improve treatment efficiency, reduce dust, and improve production efficiency. The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

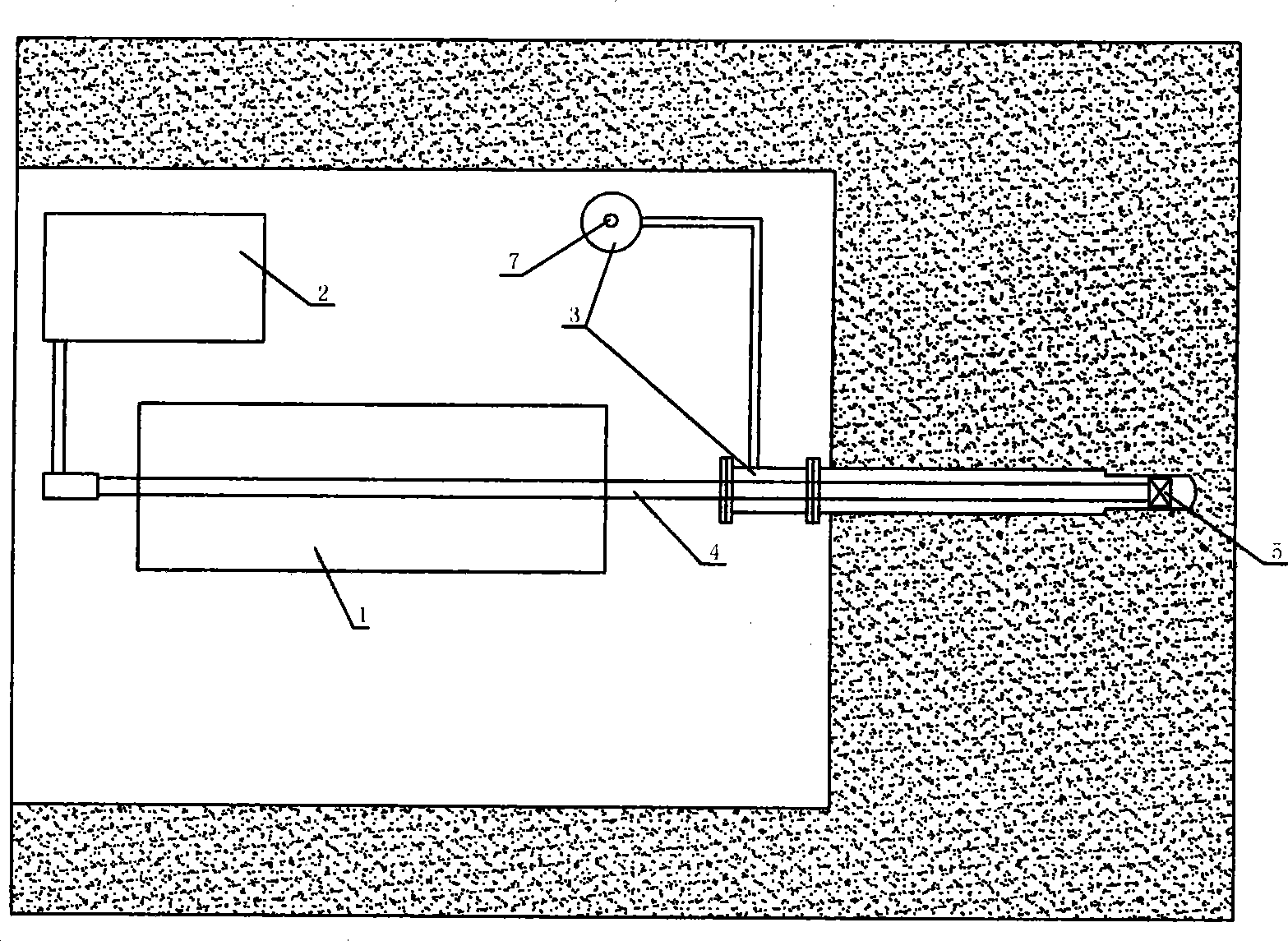

[0024] see figure 1 , the pneumatic air drilling equipment in the soft and protruding coal seam under the coal mine according to the present invention includes a drilling rig, an air compressor, an orifice dust collection and dust removal device, a high-strength large through-hole drill pipe, an inner core automatic shedding drill bit and an antistatic explosion-proof PVC screen The pipe is characterized in that: the air outlet of the air compressor is directly connected to the drill pipe with a high-pressure pipe, and the pressure air source is provided to the drill hole through the inner hole of the drill pipe.

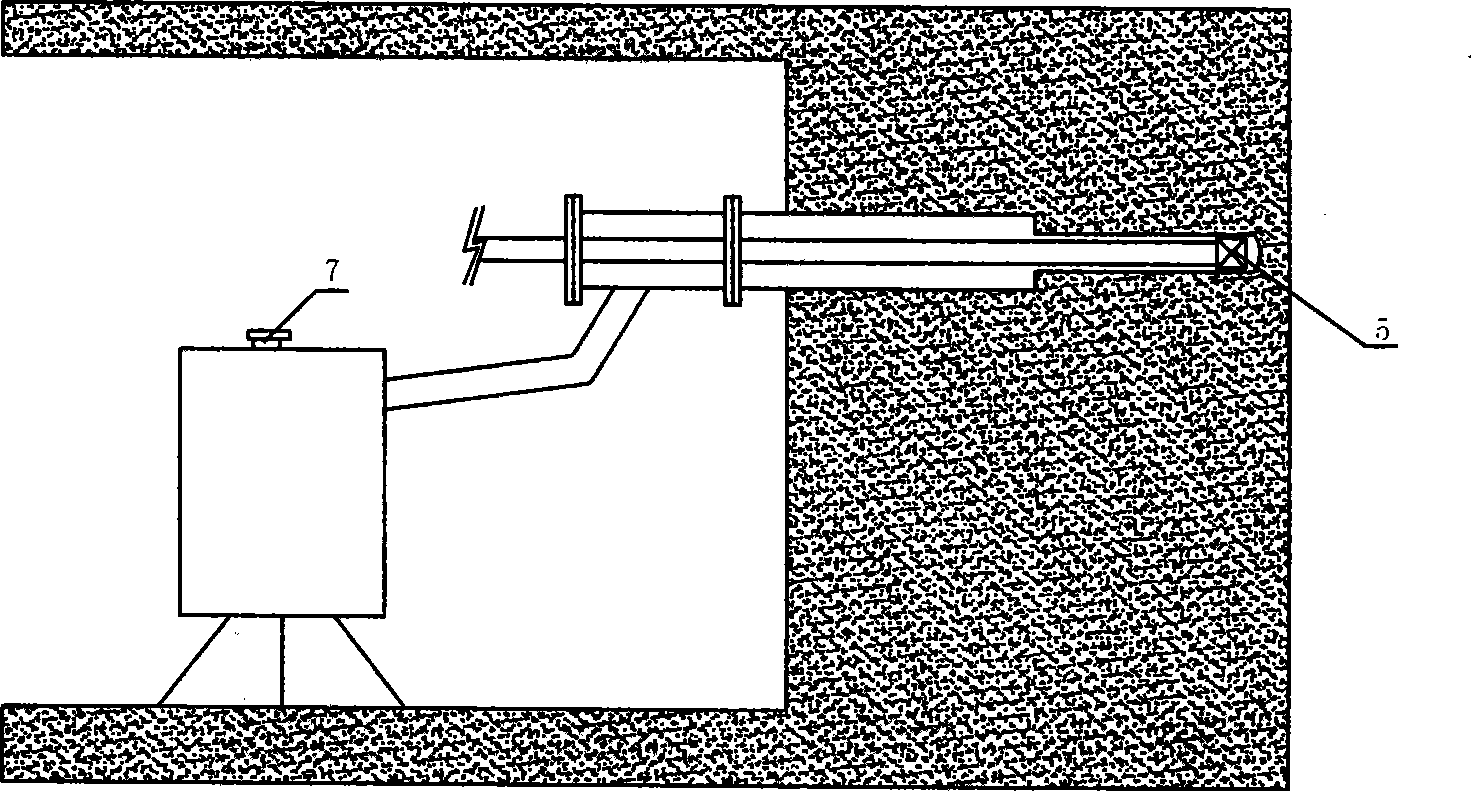

[0025] see figure 2 , the wind pressure air drilling equipment in the soft and protruding coal seam under the coal mine, the dust collection device at the orifice is directly connected with the orifice pipe, and the borehole is sealed into a closed space, which is beneficial to the unified collection and treatment of coal slag in the hole. When the wind pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com