Coal bed gas drainage method and device

A technology of coal seam gas and high-pressure water pump, which is applied in coal seam gas drainage in coal mines and in the field of gas drainage, and can solve problems such as collapsed holes, clamping drills, top drilling, injection holes, high drilling density, and small effective range of gas discharge. Achieve the effects of increasing the drilling depth and speed, preventing gas combustion accidents, and improving the air permeability of coal seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

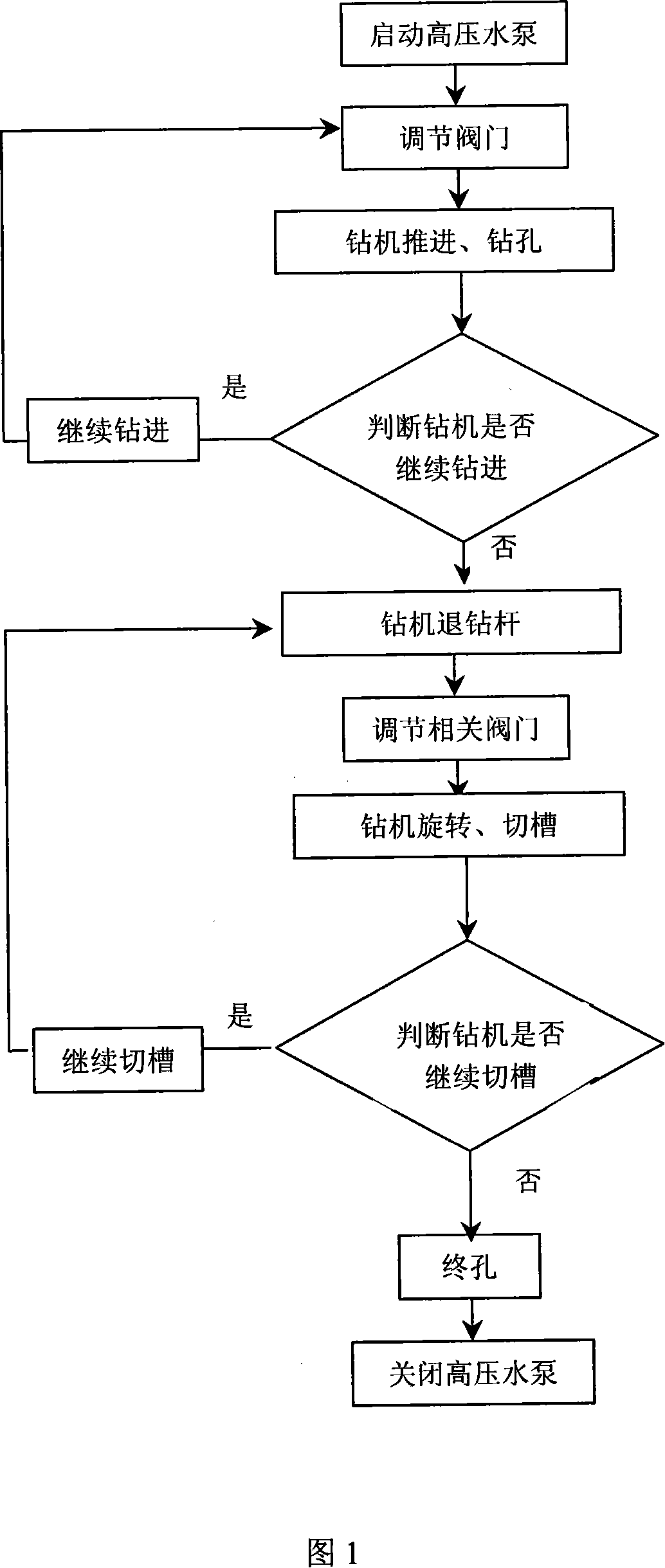

[0038] In the application of the invention in the Songzao mining area to open up the first mine, the specific process of the method is as follows:

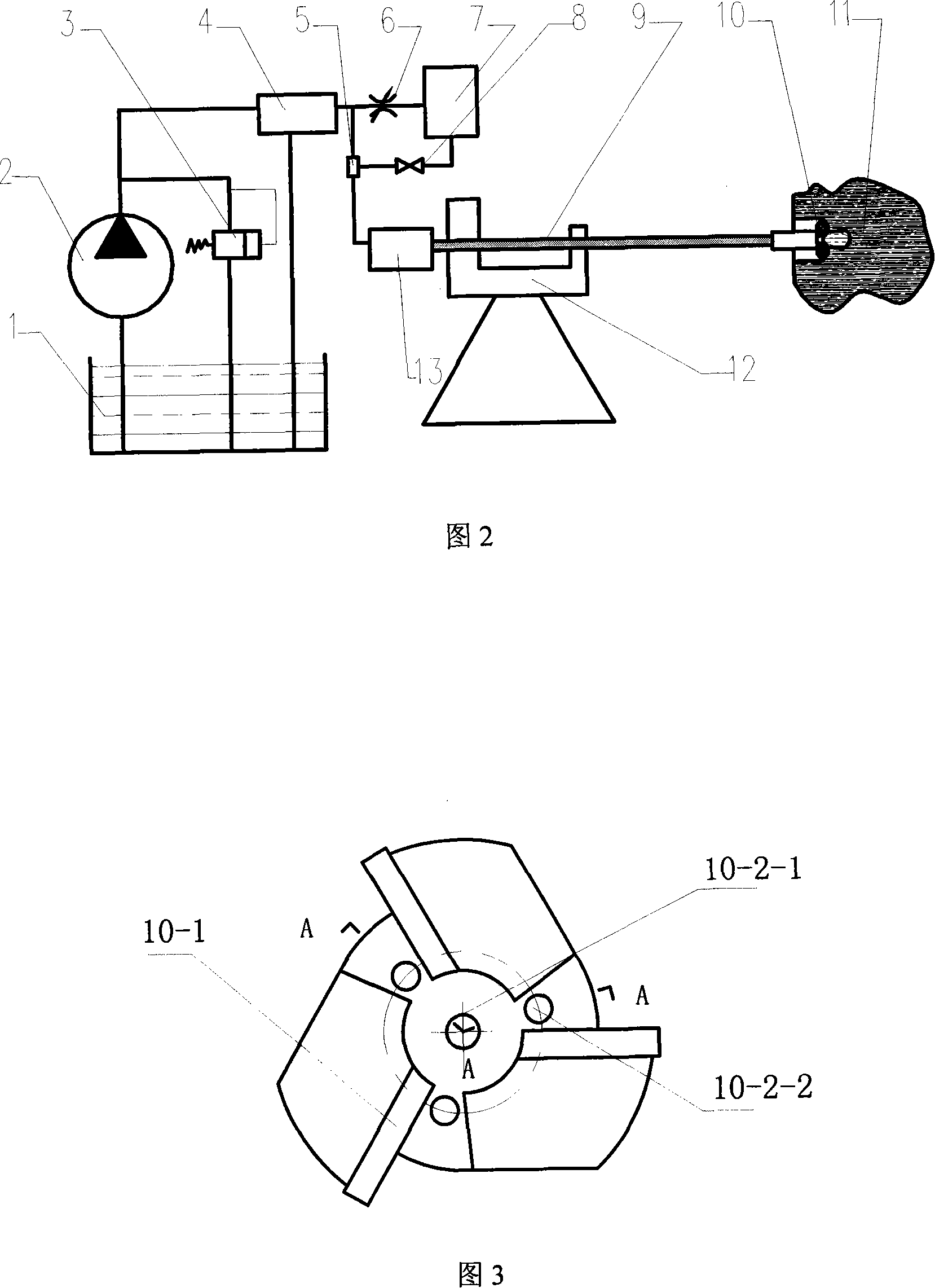

[0039] (1) Prepare the working conditions of the coal seam gas drainage device: check the firmness and sealing of the connecting pipelines in the multi-phase oscillating jet coal seam gas drainage device, and make the high-pressure water pump 3m away from the coal seam drilling point;

[0040] (2) Start the high-pressure water pump 2: The working flow of the high-pressure water pump 2 is 50L / min, and the working pressure is 10MPa;

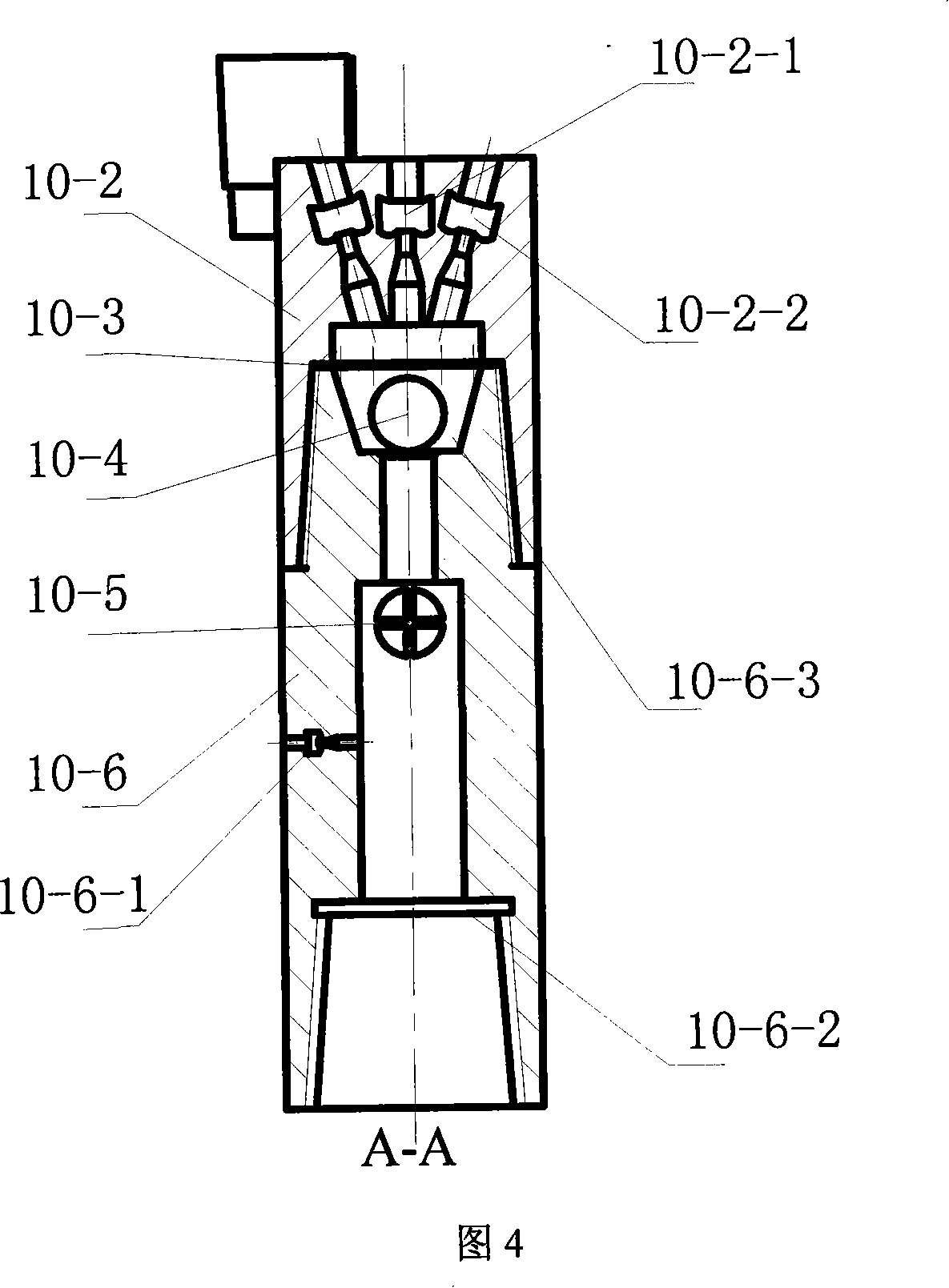

[0041] (3) Regulating valve: first open the shut-off valve 8, then open the shut-off valve 6, and then open the shut-off valve 4, so that the high-pressure water enters the mixing chamber 5 through the high-pressure water pipe and mixes with the abrasive from the abrasive tank, and then passes through the high-pressure airtight rotator 13. Then through the drill rod 9, a multi-phase oscillating jet is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com