Magnetic separation device and method for ash agglomerating cinder during coal gasification course

A magnetic separation device and magnetic separation technology, which are applied in the field of coal gasification, can solve the problems that the magnetic separation technology of ash-aggregated smelting coal slag has not been industrialized, and achieve the effects of low energy consumption, comprehensive benefits of efficiency enhancement, and comprehensive benefits of consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

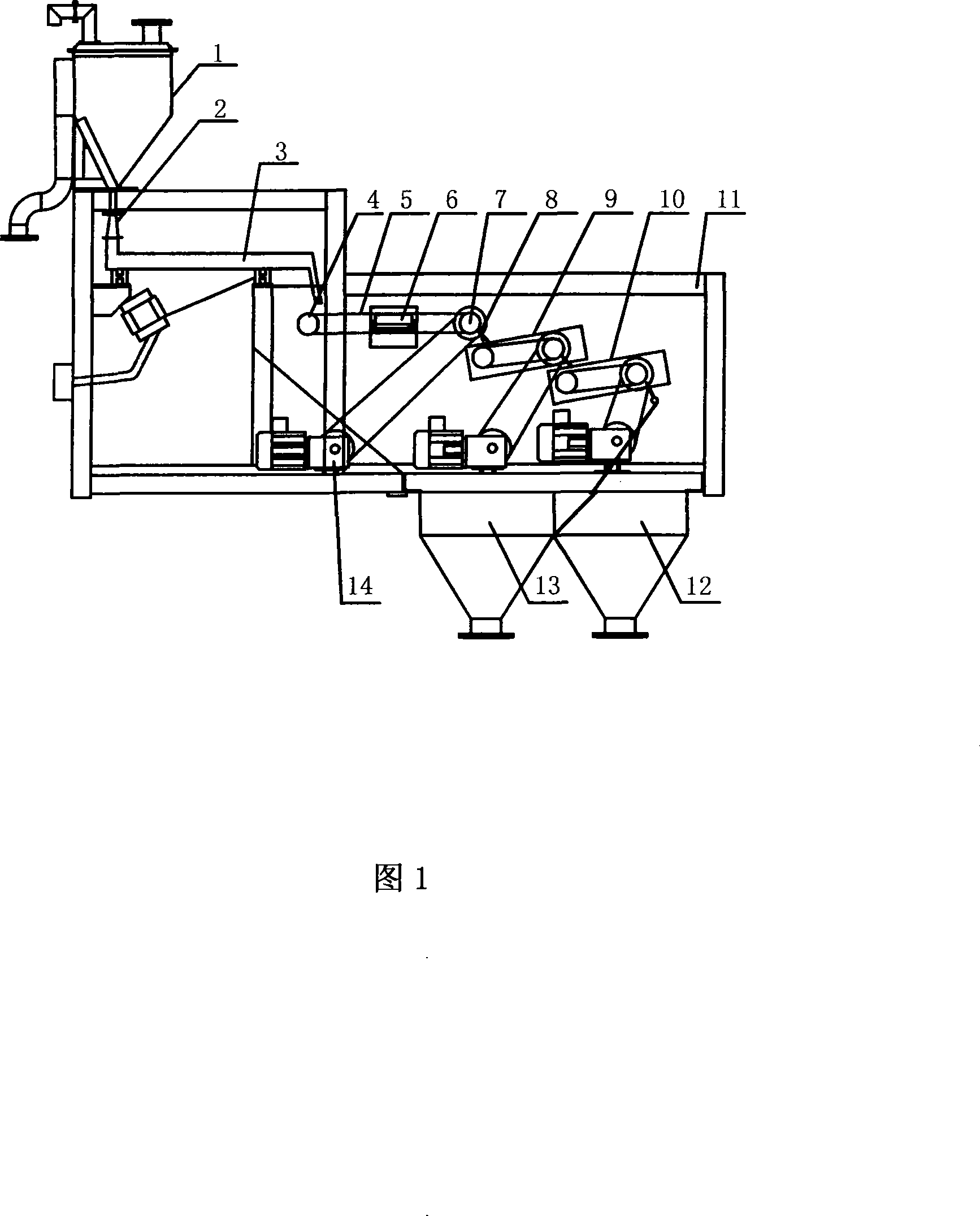

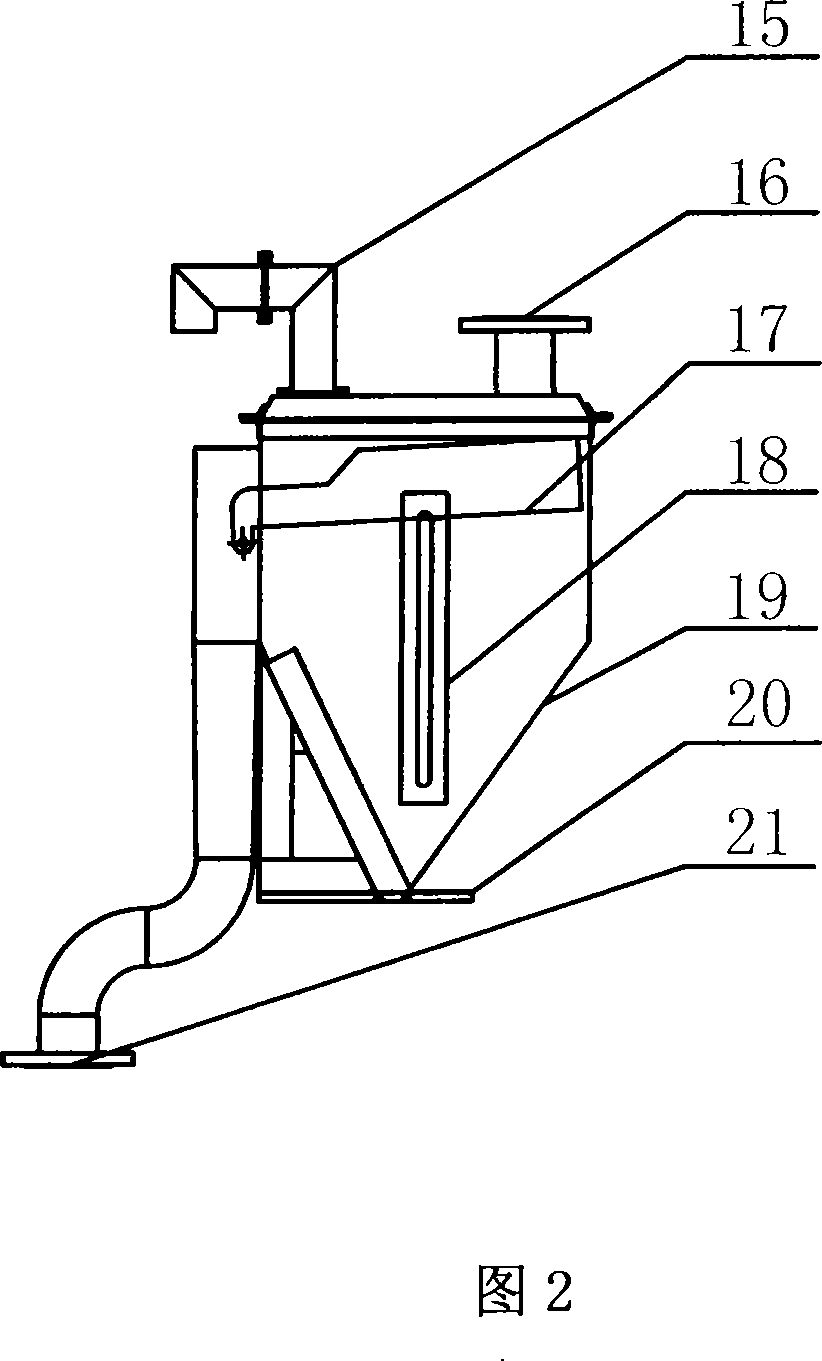

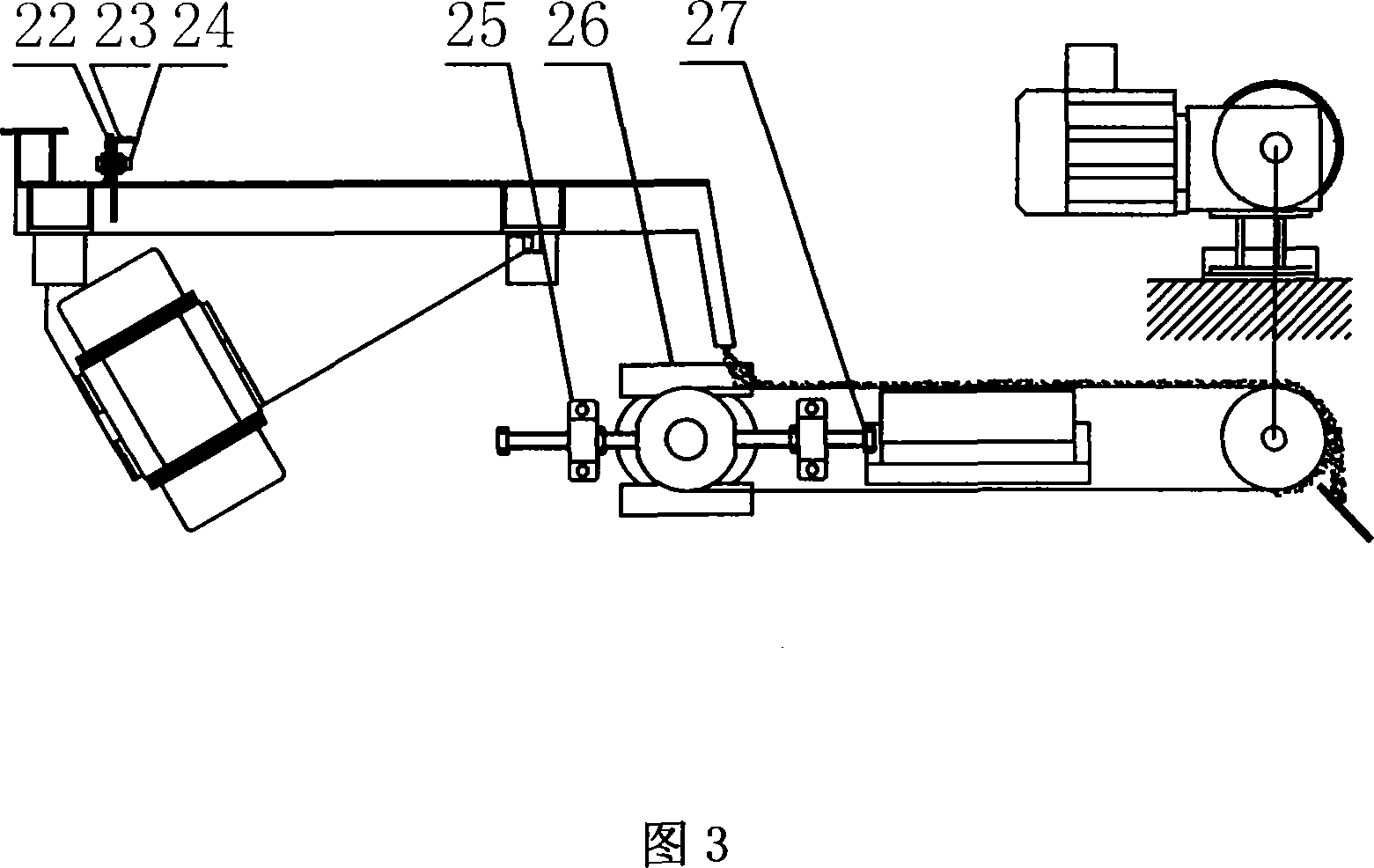

[0030] As shown in Figure 1, the magnetic separation device for ash fusion and coal slag of the present invention includes: feeding device 1, soft connector 2, vibrating feeder 3, rubber roller 4 (driven roller), ultra-thin wear-resistant transmission Belt 5, flat magnetic pole pretreatment device 6, high field strength permanent magnet roller (drive roller) 7, material distribution plate 8, box body 11, low magnetic agent lower hopper 12, high magnetic agent lower hopper 13, frequency conversion reducer 14;

[0031] Among them, the feeding device 1 is connected with the vibrating feeder device 3 through the soft connection 2; the frequency conversion reducer 12 drives the high-field strength permanent magnet roller (driving roller) 7, rubber roller 4 (driven roller), ultra-thin The wear-resistant conveyor belt 5 forms a first-level pre-magnetization an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com