Oil coal cinder extracting process and equipment

An extraction equipment and extraction technology, which are applied in the petroleum industry, solvent extraction, and tar processing through selective solvent extraction, can solve the problems of equipment and process technology not yet owned by my country, expensive equipment investment, and large environmental pollution. Achieve the effect of saving solvent and water resources, reducing oil import pressure, and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

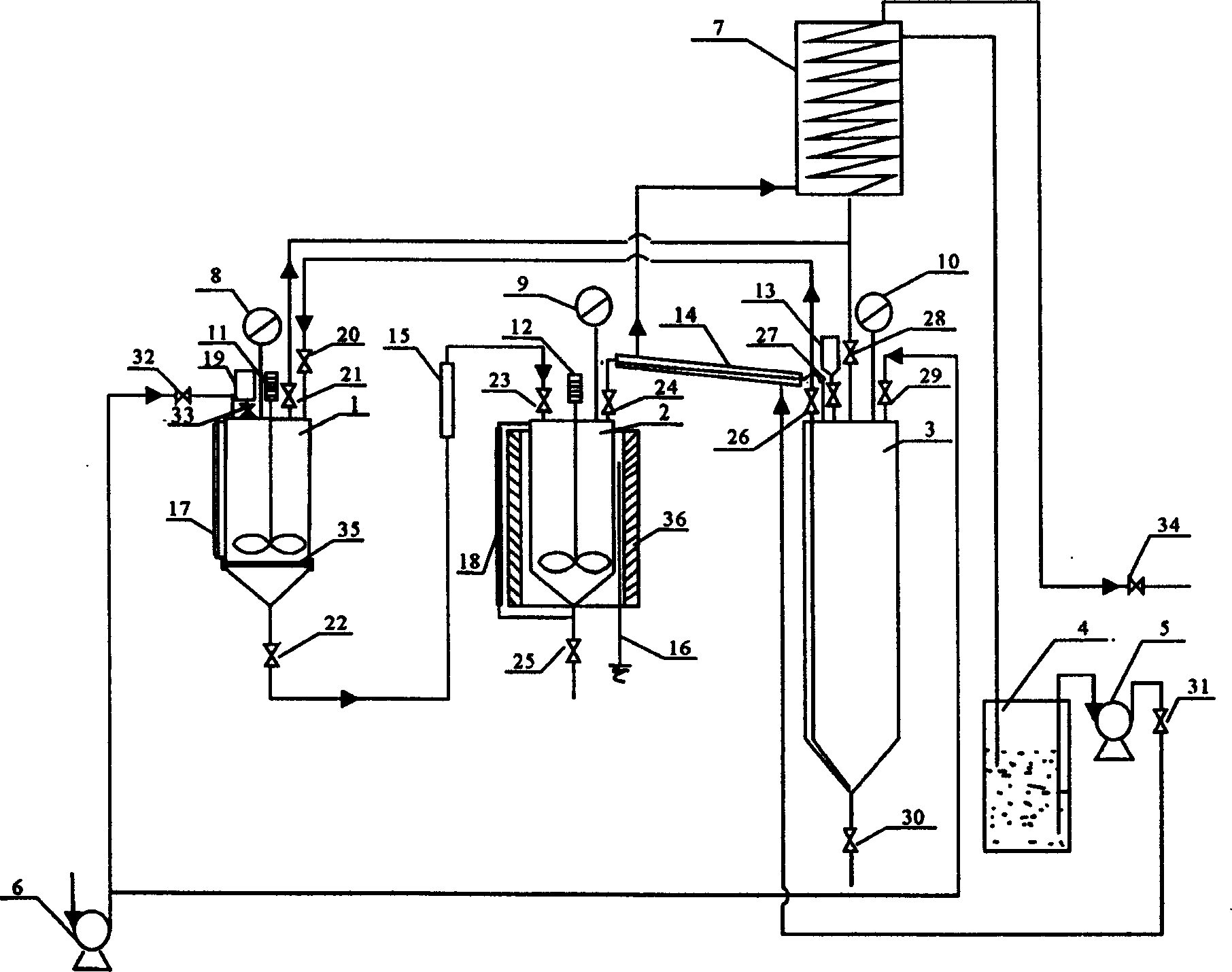

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

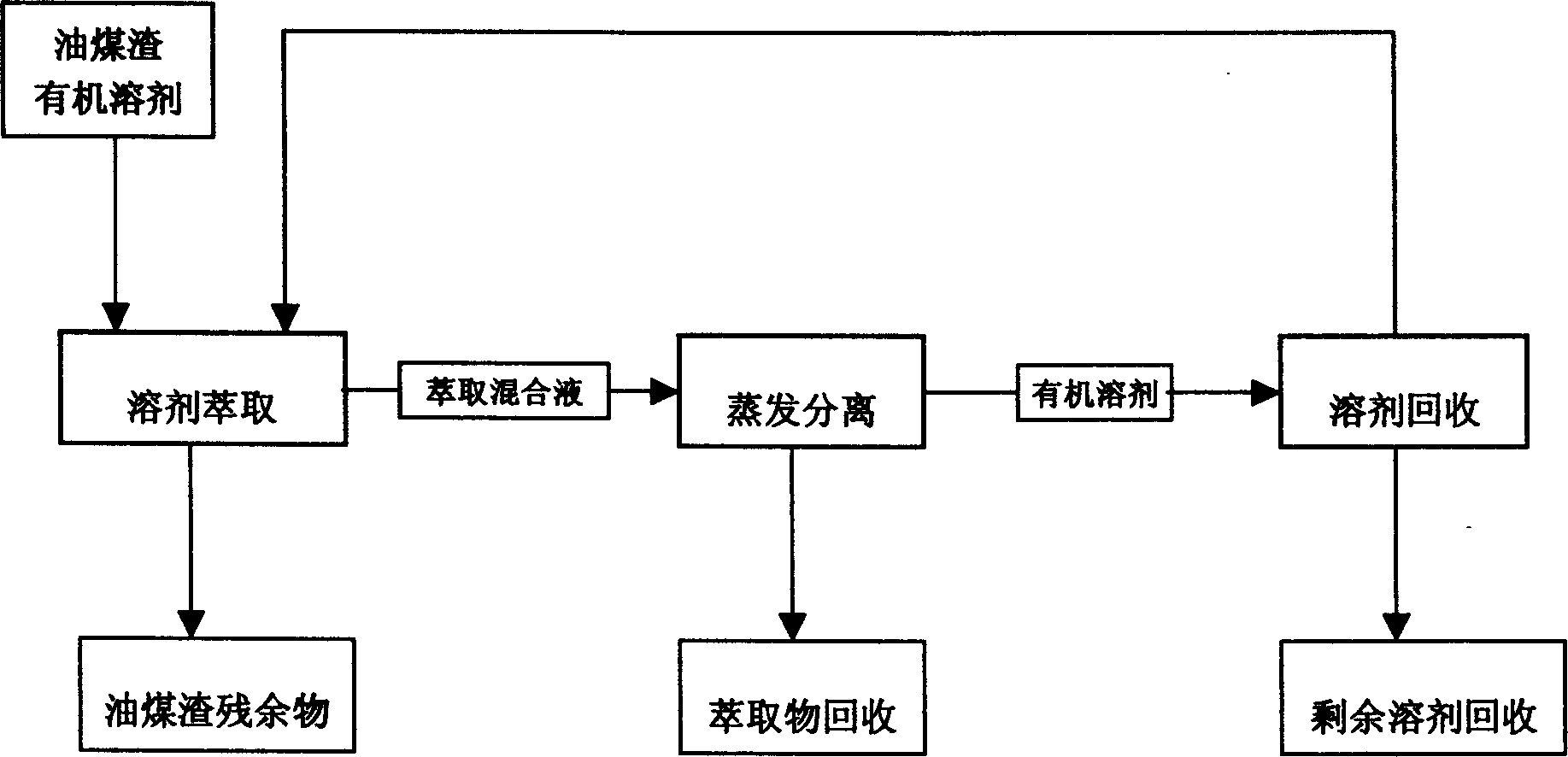

[0017] The implementation process of the oil-coal slag extraction process of the present invention:

[0018] (1) Solvent extraction operation: open the feeding tank 19 and its valve 33 on the upper part of the extraction kettle 1, add Shenfu coal (bituminous coal) and benzene in the extraction kettle 1, close the feeding tank 19 and its valve 33, and then open the valves 21, 28 , 34, other valves are closed; open the magnetic stirrer 11 and adjust the rotation speed for extraction; when the extraction reaches equilibrium, close the magnetic stirrer 11 and close the valve 21.

[0019] (2) Extraction mixture separation operation: open valve 31, open water pump 5, make the water in the water tank 4 flow back in the water tank 4 through condenser 14 and condenser 7 again; Open valve 32,22,23,24,28, 34. Other valves are closed; turn on the air compression pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com