Double-cyclone coal pyrolysis gasification step converting device and double-cyclone coal pyrolysis gasification step converting method

A conversion device and double cyclone technology, which is applied in the gasification of granular/powder fuel, the manufacture of combustible gas, the petroleum industry, etc., can solve the problem of not being able to reasonably recover the high temperature sensible heat of coal gas, and achieve high-efficiency coal pyrolysis gasification classification conversion , mild reaction conditions, high pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

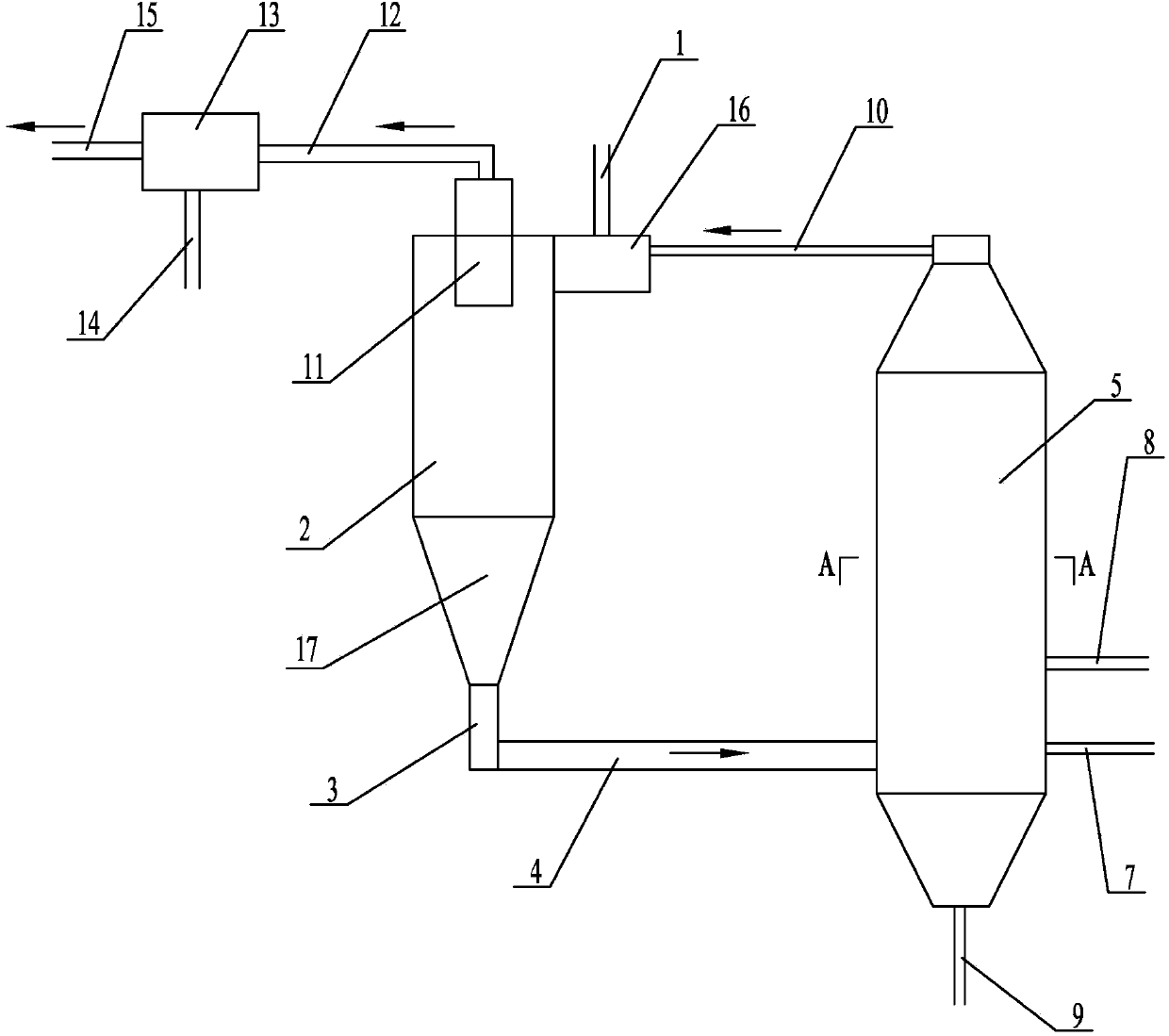

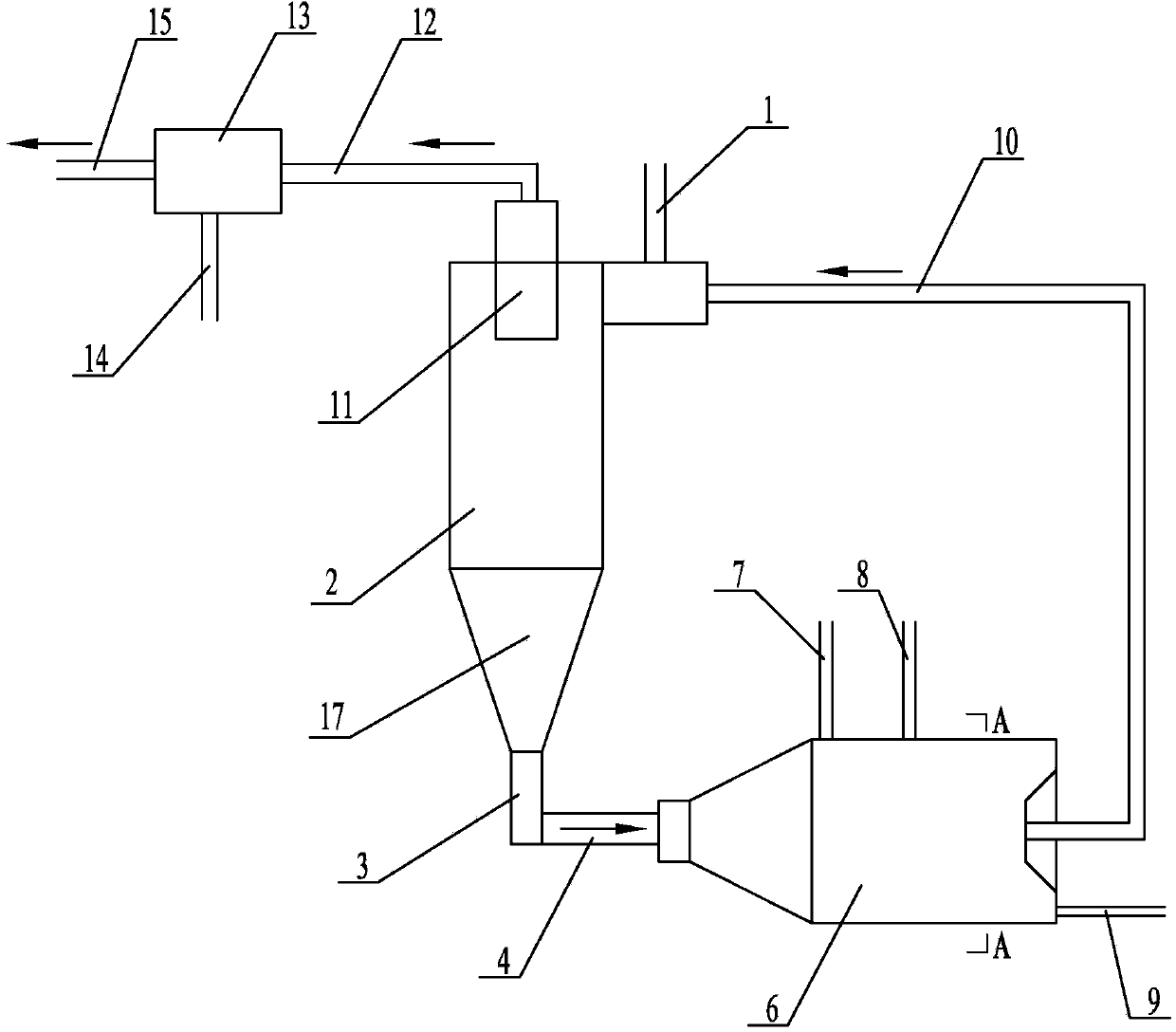

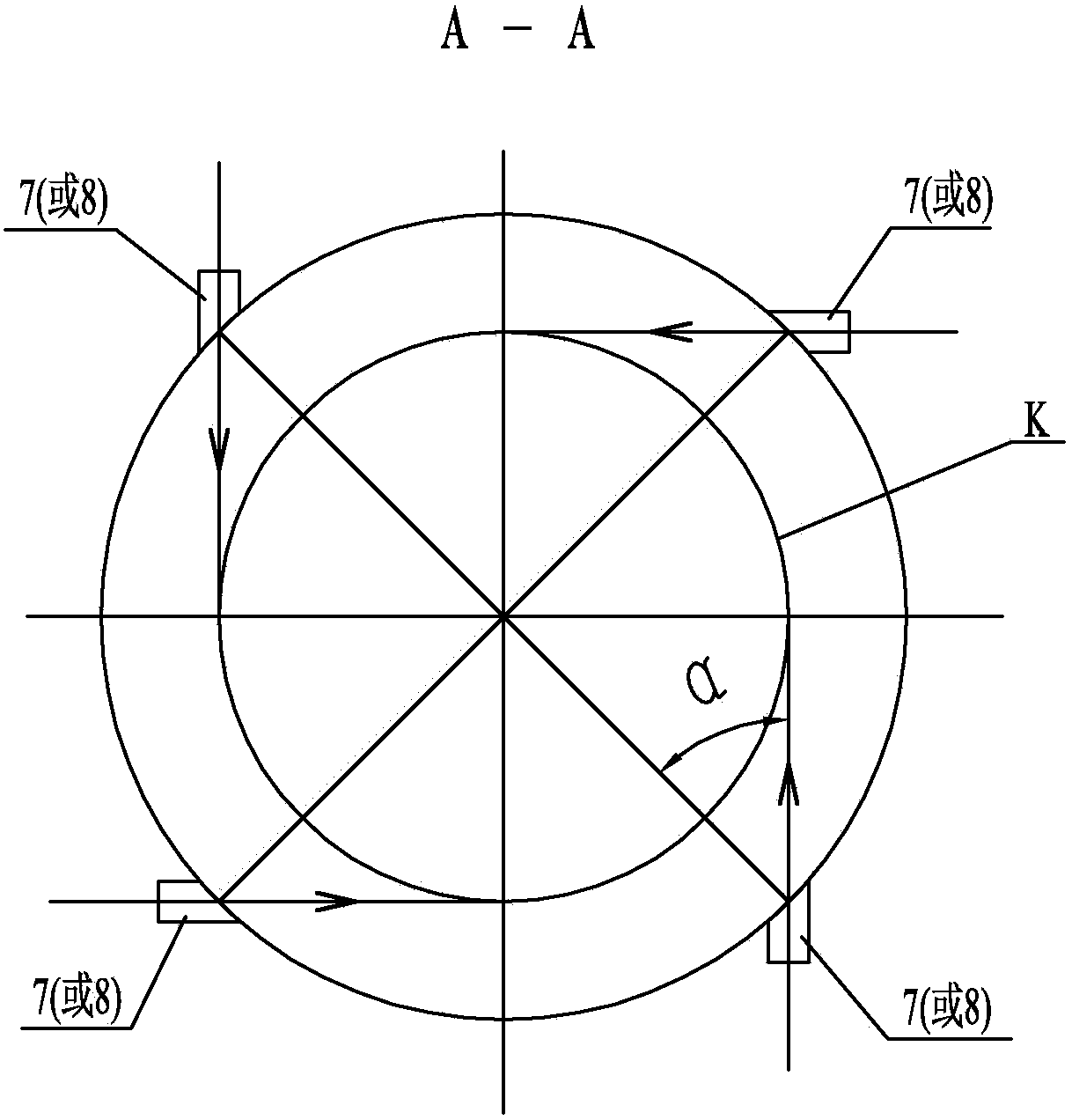

[0021] Specific implementation mode one: combine figure 1 and figure 2 This embodiment is described. This embodiment includes a cyclone pyrolysis furnace 2, a feeding device 3, a pyrolysis semi-coke channel 4, a cyclone gasification furnace 5, a high-temperature crude gas channel 10, a cyclone pyrolysis furnace exhaust pipe 11, and a pyrolysis furnace. Gas mixing channel 12, cooling device 13, crude synthesis gas connecting pipe 15, coal feeding connecting pipe 16, material legs 17, several oxidant nozzles 7 and several steam nozzles 8, coal feeding connecting pipe 16 is installed on the upper end of cyclone pyrolysis furnace 2 , the exhaust pipe 11 of the cyclone pyrolysis furnace is installed on the top of the cyclone pyrolysis furnace 2, and the coal inlet 16 is provided with a coal feeding inlet 1. One end of the semi-coke decomposing channel 4 communicates with the feed-reversing device 3, the other end of the pyrolysis semi-coke channel 4 communicates with the lower pa...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 and figure 2 The present embodiment will be described. The cyclone gasifier 5 of the present embodiment is a vertical cyclone gasifier or a horizontal cyclone gasifier. The vertical wind gasifier is suitable for gasifying pulverized coal with small particle size, and the horizontal cyclone gasifier is suitable for gasifying coal particles with large particle size. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the dipleg 17 of this embodiment is conical, the diameter of the upper end of the cone is larger than the diameter of the lower end, and the height of the dipleg 17 is 1m-2m. The longer material leg 17 can play a sealing role to ensure the pressure difference between the cyclone pyrolysis furnace 2 and the cyclone gasification furnace 5 . Other compositions and connections are the same as those in Embodiment 1 or 2.

[0024] Specific implementation mode four: combination figure 1 and figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0025]Step 1: The pulverized coal enters the coal inlet connecting pipe 16 from the coal feeding inlet 1, and the pulverized coal uses liquid or gas fuel in the high-temperature crude gas (system start-up stage), and injects the fuel from an ignition oil gun arranged near the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com