Renewable unfired filter material and preparation method, application and regeneration method thereof

A filter material and industrial technology, applied in the field of renewable burn-free filter material and its preparation, can solve the problems of difficult processing and high processing cost, and achieve huge economic and social value and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides the preparation method of above-mentioned technical scheme filter material, comprises the following steps:

[0059] Mix silicon-aluminum industrial solid waste with construction waste, add alkali activator or sludge for first stirring, then add sludge or alkaline activator and foaming agent for second stirring, and stop stirring after forming a uniform slurry. Stand still to obtain filter material.

[0060] The preparation method of filter material more specifically comprises:

[0061] Mix silicon-aluminum industrial solid waste with construction waste, add alkali activator for first stirring, then add sludge and foaming agent for second stirring, stop stirring after forming a uniform slurry, let stand, and obtain filter material; or

[0062] Mix silicon-aluminum industrial solid waste with construction waste, add sludge for first stirring, then add alkaline activator and foaming agent for second stirring, stop stirring after forming...

Embodiment 1

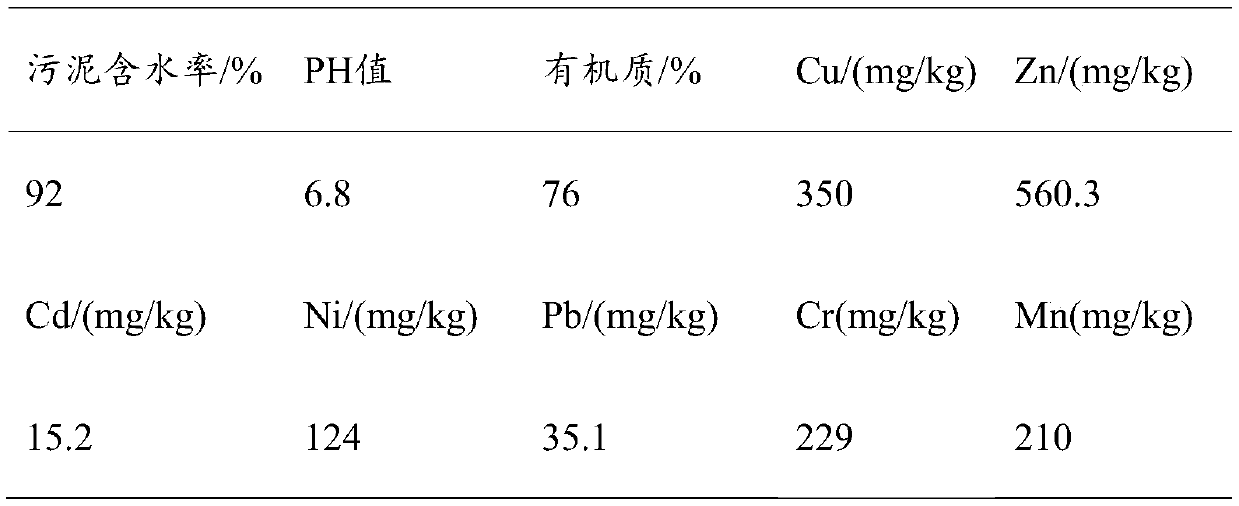

[0091] The present embodiment carries out the preparation of ceramsite filter material, and preparation raw material is: the mixture of silico-aluminum industrial solid waste is 30 parts of fly ash, 20 parts of metakaolin and 50 parts of cinder, and alkali activator is 50 parts of water glass (water glass It is the aqueous solution of sodium silicate, the modulus is 3.2, the content is 47wt%, the Baume degree is 45°) and 10 parts of sodium hydroxide (analytical pure) mixture, the construction waste is the waste concrete produced by the demolition of old houses in a community in Guangzhou A total of 25 parts of blocks and waste bricks, the sludge is 50 parts of sludge from a water purification plant in Baiyun District, Guangdong (the sludge composition is as shown in Table 1), and the blowing agent is 2 parts of hydrogen peroxide (content is 30wt%, analytically pure), The mass ratio of silicon-aluminum industrial solid waste, alkali activator, construction waste, sludge and blow...

Embodiment 2

[0106] This embodiment carries out the preparation of spherical filter material, and the preparation raw material is the mixture of 20 parts of sulfur-fixed ash, 20 parts of carbide slag, 15 parts of slag and 45 parts of metakaolin for the preparation of silicon-aluminum industrial solid waste, and the alkali activator is 60 parts of water. A mixture of glass (modulus 3.3, content 37wt%, Baume degree 40°) and 12 parts of potassium hydroxide (analytically pure, content > 90%), construction waste is the waste produced by the excavation of urban roads in the suburbs of Guangzhou City. There are 40 parts of concrete blocks and slag, 60 parts of sludge from a water supply plant in Guangzhou (water content 95%), and 4 parts of sodium bicarbonate as foaming agent. The mass ratio of silicon-aluminum industrial solid waste, alkali activator, construction waste, sludge and blowing agent is 100:72:40:60:4. In kg as the unit, 100kg of silicon-aluminum industrial solid waste, 72kg of alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com