Method for preparing soil conditioner from industrial solid waste

A technology of soil conditioner and industrial solid waste, which is applied in the field of preparing soil conditioner by using industrial solid waste, which can solve the problems of complicated process, chemical reaction and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

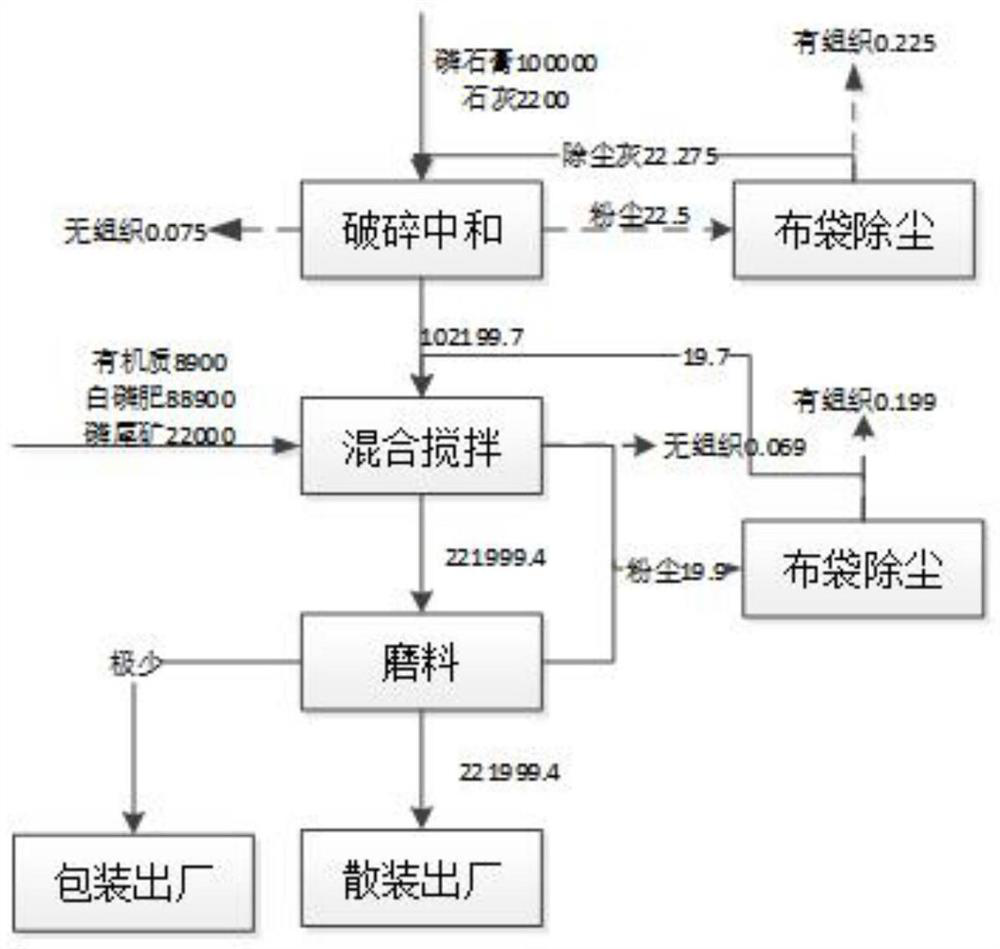

[0029] Example 1. Raw materials: 100,000 tons of raw material phosphogypsum, 2,200 tons of quicklime, 88,900 tons of white phosphorus fertilizer (that is, fertilizer-grade calcium hydrogen phosphate), 22,000 tons of phosphorus tailings, and 8,900 tons of organic matter.

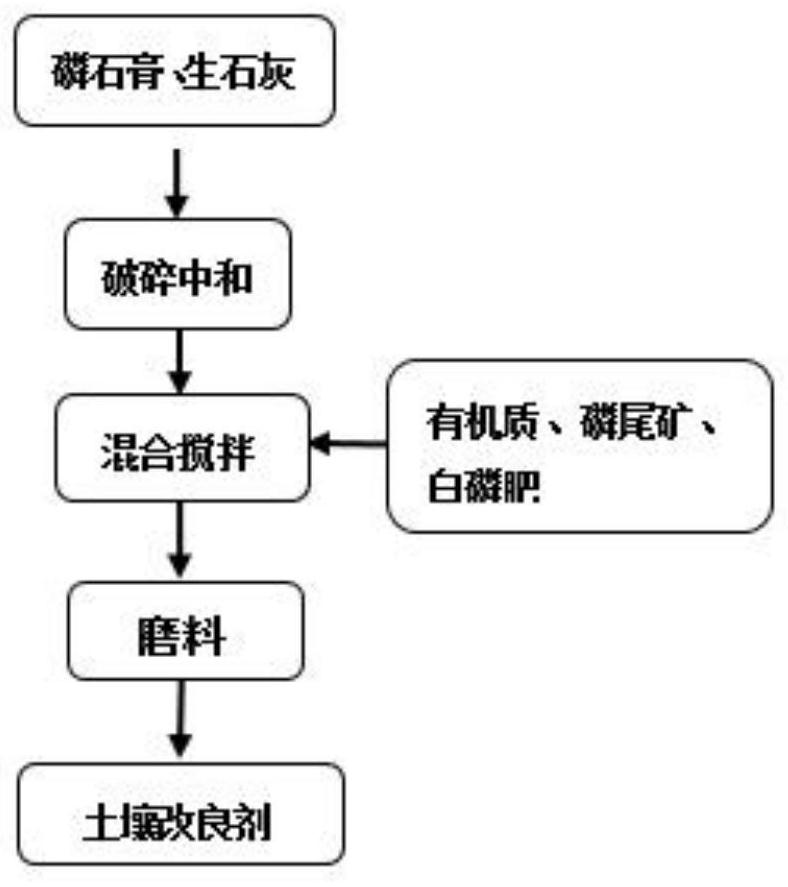

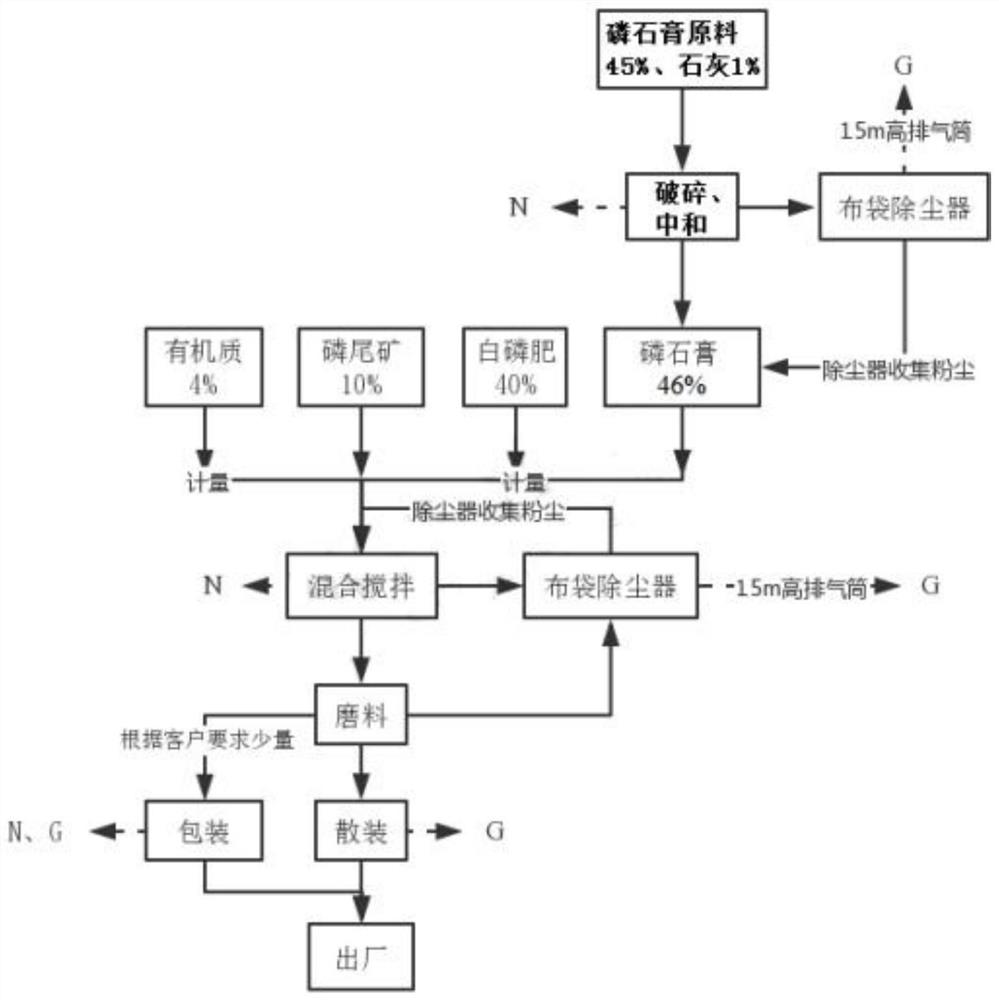

[0030] Utilize above-mentioned raw material to prepare the method for soil conditioner, technique is as follows Figure 1-3 shown, follow the steps below:

[0031] (1) Crushing and neutralization: The raw material phosphogypsum is crushed and neutralized in the crusher after adding quicklime, solidified fluoride, and modified to a pH value of 7-8 to obtain modified phosphogypsum. This process will generate certain dust and noise. The noise is reduced by low-noise equipment and sound insulation measures for the workshop, and the crushed dust is treated by installing a bag filter on the crusher and then discharged through a 15m high exhaust pipe;

[0032] (2) Mixing and stirring: measure and weigh the modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com