Method for extracting iron washed ore from fly ash or slag

A technology for fly ash and iron concentrate, applied in chemical instruments and methods, solid waste removal, magnetic separation, etc., can solve the problems of resource interconnection, integration, high extraction cost, and unsystematic extraction research. Achieve the effect of reducing energy consumption, reducing the difficulty of waste residue treatment, and improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0060] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

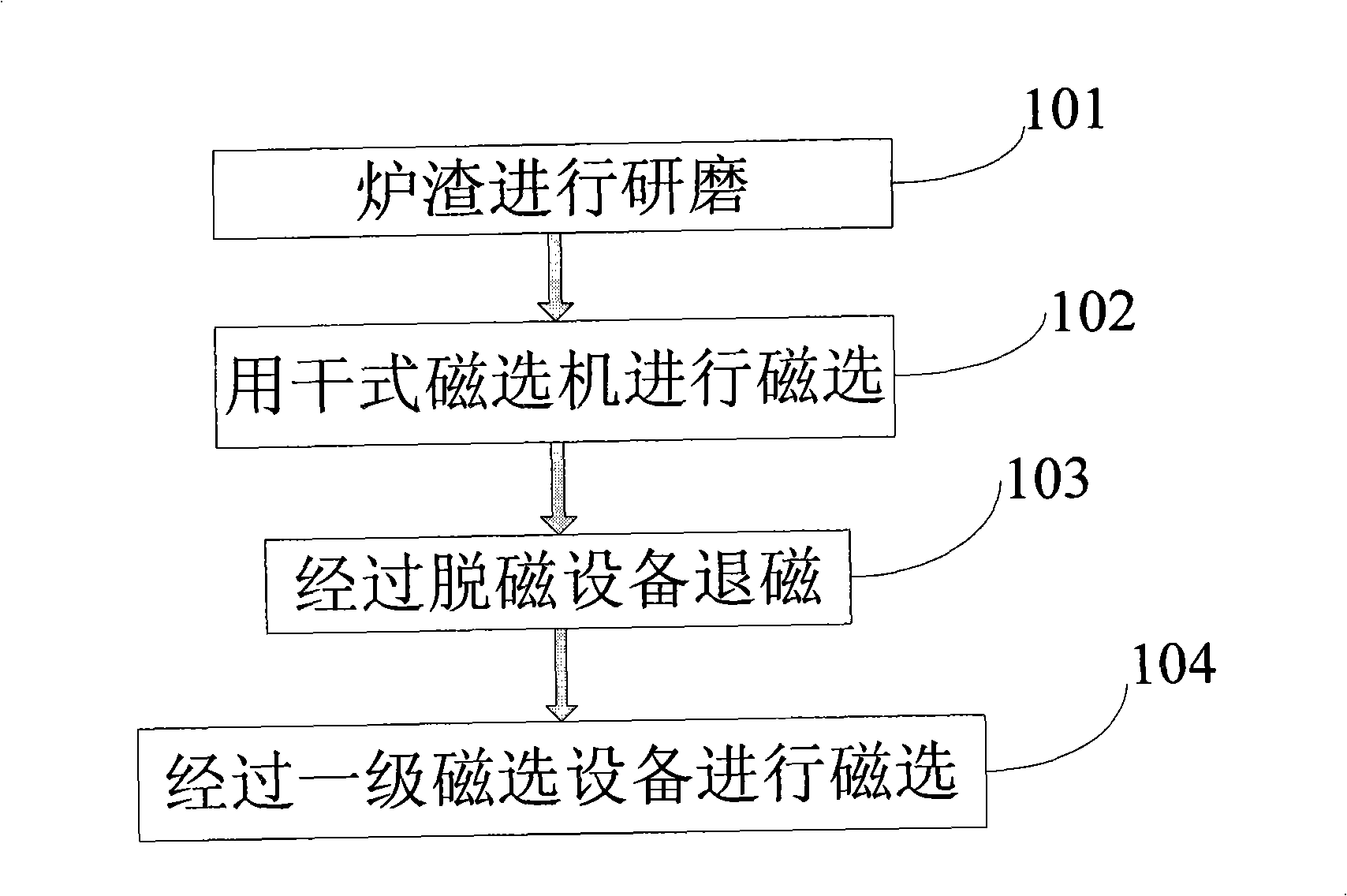

[0061] like figure 1 As shown, when extracting fine iron ore powder from fly ash or slag, it can be realized through the following steps:

[0062] 101: First, grind the slag to a fineness of 200-250 mesh with a stirring ball mill JM-260, and the fly ash does not need to be ground;

[0063] 102: Fly ash or ground slag is magnetically separated with a dry magnetic separator XCGII120×(30+30), and the magnetic field strength is 1100-1300 Oersted, and about 45% of iron oxide (mass fraction) can be obtained Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com