Raw coal initial cleaning treatment process

A technology for clean processing and raw coal, applied in grain processing, magnetic separation, solid separation, etc., can solve the problems of conveying bandwidth, large quality, and labor intensity of workers, and achieve the effect of reducing labor intensity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

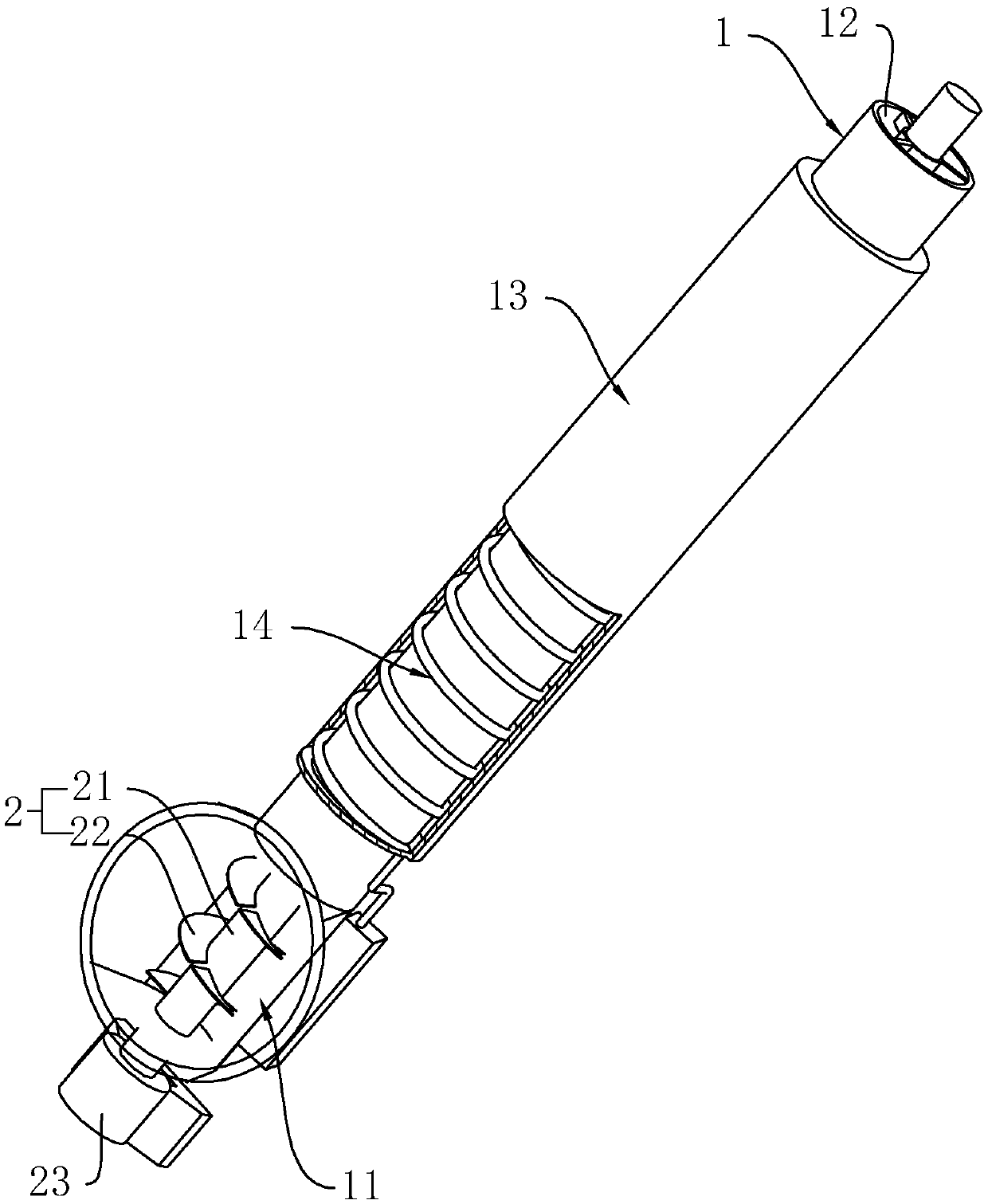

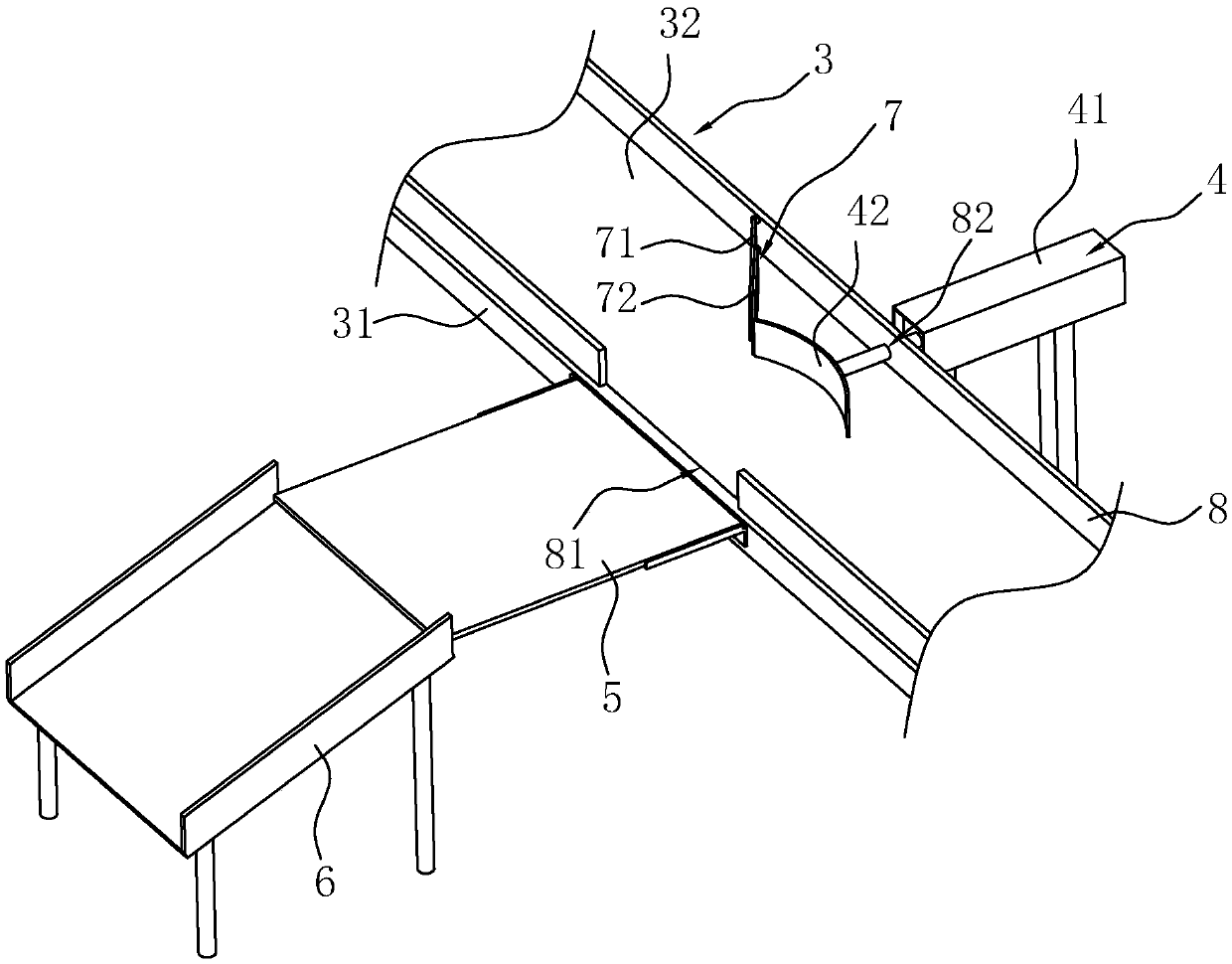

[0044] Embodiment: a kind of raw coal initial cleaning process, such as figure 1 shown, including the following steps:

[0045] Step 1, raw coal feeding: the raw coal is sent to the breaking heating feeding device through the first-level conveying equipment, the raw coal is heated, broken up and delivered, and the raw coal feeding is realized, and the heating temperature is 40-55°C;

[0046] Step 2, primary magnetic screening of raw coal: preliminary separation of iron-containing impurities in the raw coal that has been loaded in step 1 through magnetic screening; The operation is: sieve the raw coal processed in step 2 through a sieve with an aperture of 50 mm, and sieve the raw coal into coarse sieves with a particle size of 0-50 mm, and the rest are coarse sieves;

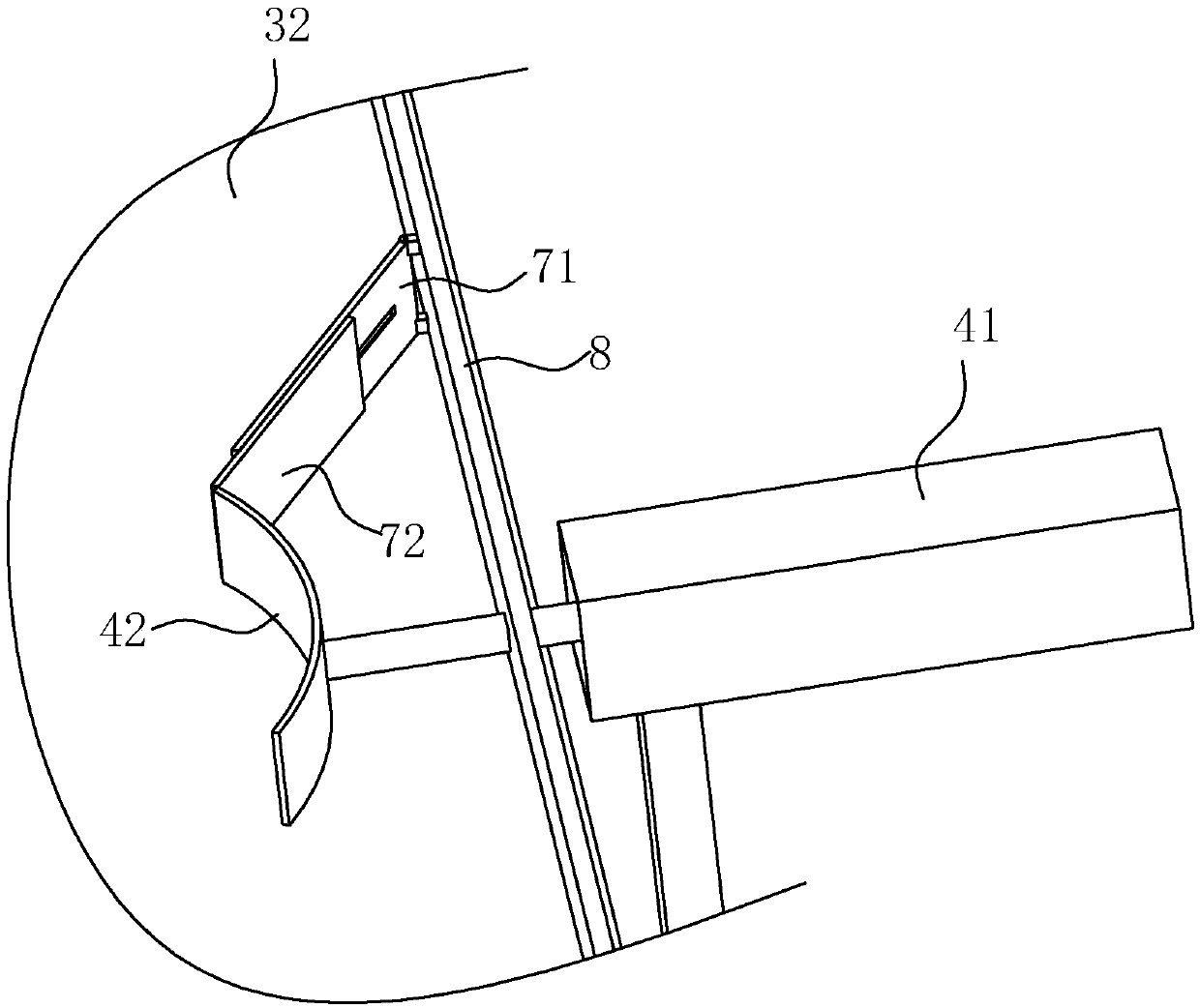

[0047] Step 4, initial rough selection of gangue: including the following steps:

[0048] a, the coarse sieve in step 3 is sieved again through a screen, and divided into first-class raw coal with a particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com