Water retention type humic acid bio-organic fertilizer and preparation method

A bio-organic fertilizer and humic acid technology, applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve problems such as soil environmental pollution, human health threats, soil salinization, etc., to promote crop growth, The effect of improving soil physical and chemical properties and reducing the use of nitrogen fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

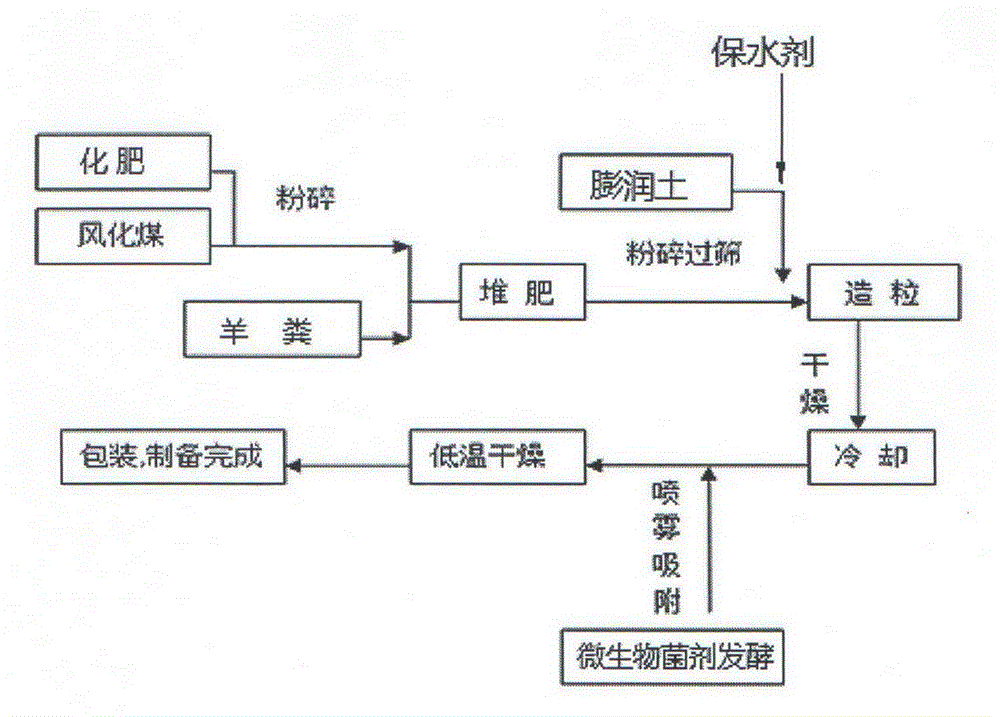

Method used

Image

Examples

Embodiment 1

[0018] First prepare chemical fertilizer, by weight urea: diammonium phosphate: potassium sulfate=2:1:1 mixing;

[0019] Then prepare the mixed microbial bacterial agent, with Lactobacillus sporogenes, Bacillus megaterium, Bacillus licheniformis respectively through inclined-plane activation, expansion culture, centrifugal concentration according to conventional methods, by volume ratio Lactobacillus sporogenes bacterial liquid: Bacillus megaterium bacterial liquid: licheniformis Bacillus bacteria solution = 1:1:1 mixed to obtain mixed microbial bacteria agent;

[0020] Prepare the water-retaining agent mixture, mix by mass ratio polyacrylamide: sodium alginate: agar=6:3:1;

[0021] According to the percentage by weight, 22% of the weathered coal and 5% of the mixture of chemical fertilizers such as urea, diammonium phosphate and potassium sulfate are respectively crushed by a pulverizer and mixed with 60% of dry sheep manure, and the moisture content of the mixed material is ...

Embodiment 2

[0025] Preparation of chemical fertilizers, mixing microbial inoculum and water retaining agent mixture, all carried out according to Example 1;

[0026] According to the percentage by weight, 40% of weathered coal and 4% of the mixture of chemical fertilizer urea, diammonium phosphate and potassium sulfate are respectively crushed by a pulverizer and mixed with 50% of dry sheep manure, and the moisture content of the mixed material is adjusted to 60%. , carry out compost fermentation, compost for 40 days, and the raw materials are completely decomposed;

[0027] After pulverizing the decomposed raw materials, pass through a 80-mesh sieve to obtain a powder, then add 5% bentonite and 1% water-retaining agent of a mixture of polyacrylamide, sodium alginate and agar, mix well and then granulate, and dry at 210°C To the water content of 8%, after cooling, the granules are obtained;

[0028] The obtained granules are sprayed with 30ml of mixed microbial agent per 1kg. Afte...

Embodiment 3

[0030] Preparation of chemical fertilizers, mixing microbial inoculum and water retaining agent mixture, all carried out according to Example 1;

[0031] According to the percentage by weight, 35% of weathered coal, 5% of the mixture of chemical fertilizers such as urea, diammonium phosphate and potassium sulfate are respectively crushed by a pulverizer and mixed with 54% of dry sheep manure, and the moisture content of the mixed material is adjusted to 60%. , carry out compost fermentation, compost for 35 days, and the raw materials are completely decomposed;

[0032] After pulverizing the decomposed raw materials, pass through an 80-mesh sieve to obtain a powder, then add 5% bentonite and 1% water-retaining agent of a mixture of polyacrylamide, sodium alginate and agar, mix well and then granulate, and dry at 150°C To the water content of 8%, after cooling, the granules are obtained;

[0033] The obtained granules are sprayed with 40ml of mixed microbial agent per 1kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com