Comprehensive reclaiming method for pyrite slag

A technology of pyrite slag and recovery method, which is applied in chemical instruments and methods, process efficiency improvement, solid separation and other directions, can solve problems such as limiting the scope of use, and achieve the effects of improving reduction intensity, saving resources and controlling pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

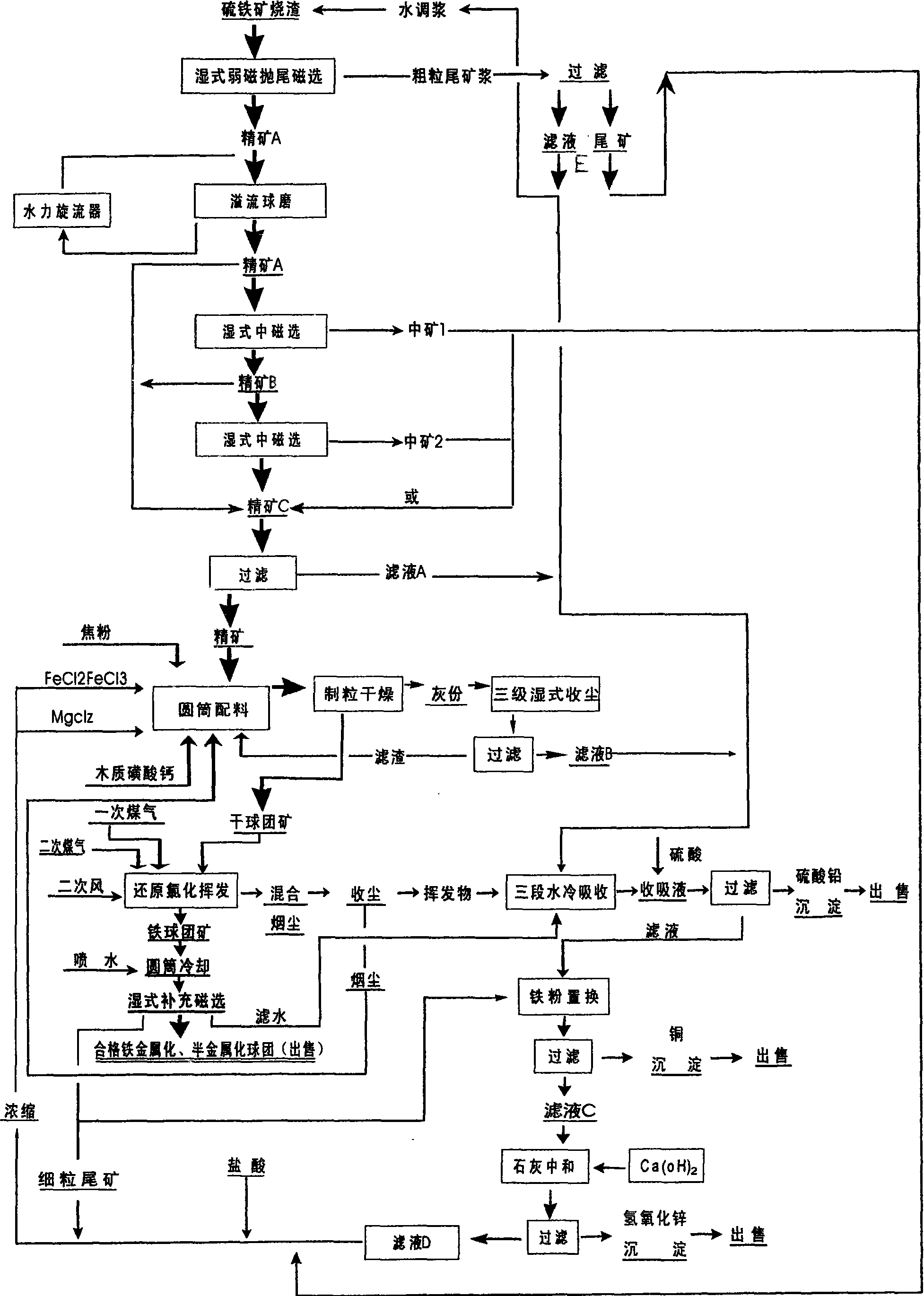

Image

Examples

Embodiment Construction

[0010] The raw material of Examples 1-3 is pyrite slag from Zizhong, Sichuan, and its chemical composition is shown in Table 1. The results after overflow ball milling and wet magnetic separation are shown in Table 2. The results of reduction chlorination volatilization and comprehensive recovery are shown in Table 3. The magnetic separation results are shown in Table 4.

[0011] Table 1: Main chemical composition of pyrite slag (%)

[0012] Fe

S

P

As

Cu

Pb

Zn

Au g / t

Ag g / t

SiO 2

CaO

Al 2 o 3

34-55

1-3

0.05

0.1-0.2

0.2

1-2

0.5-2

0.5-1

20-50

2-8

2-5

2-4

[0013] Table 2: Results of wet magnetic separation of pyrite slag

[0014]

project

Pyrite slag (%)

Magnetic field strength

Concentrate grade (%)

Recovery rate(%)

iron

iron

iron

sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com