Method for preparing low-grade rolled concrete by using multiple industrial waste slag

A technology of roller compacted concrete and industrial waste, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., and can solve the problems of low mixture strength, low utilization rate of waste residue, and less space for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

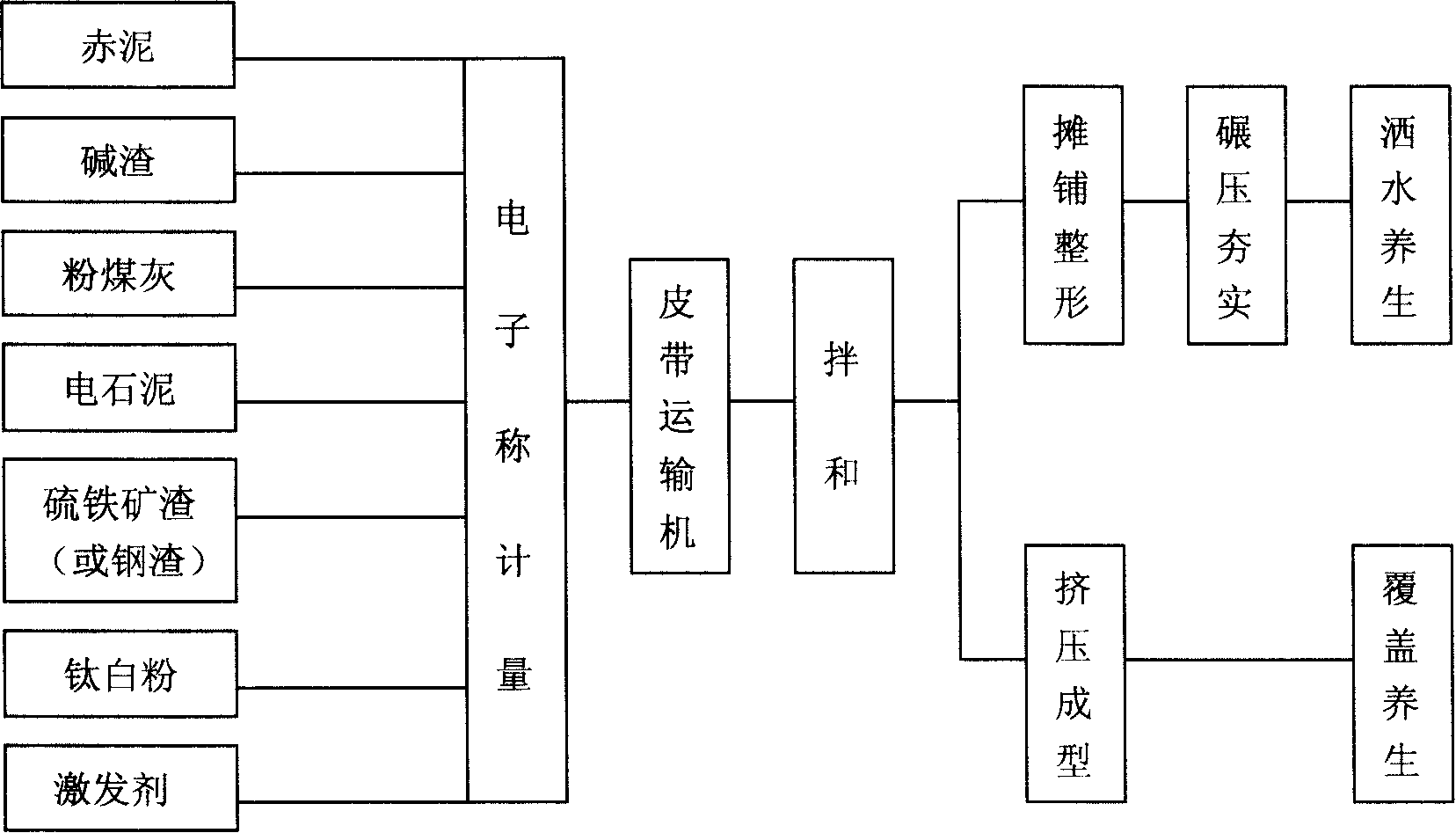

Method used

Image

Examples

example 1

[0016] 26% red mud, 20% alkali slag, 40% fly ash, 7% calcium carbide mud, 2% titanium dioxide slag, 4% pyrite slag (or steel slag), and a small amount of composite activator, used in Jiaozuo City, Henan Province For the base course of the source road test section, the unconfined compressive strength of the test piece was 3.98MPa for 3 days, 5.51MPa for 7 days, and 7.61MPa for 28 days. The test piece was insoluble in water.

example 2

[0018] 25% of red mud, 18% of alkali slag, 40% of fly ash, 14% of calcium carbide mud, 2% of titanium dioxide slag, a small amount of composite activator, adding 0.3‰ water reducing agent, and using CY500 automatic hydraulic brick making machine to make There are 1,200 standard bricks, and the average compressive strength is 11.8MPa and the average flexural strength is 3.16MPa after 28 days.

example 3

[0020] On September 18, 2006, a test section of 275 meters was paved on the second-grade road in Xiuwu County, Henan Province. 20% of coal ash, 25% of calcium carbide mud, 2% of titanium dioxide slag, and a small amount of composite activator are mixed in the construction mix, mixed with a BMW-380 road mixer, leveled with a grader, statically pressed once with a 25T road roller, and rolled twice. The smooth surface is statically pressed once, and the unconfined compressive strength of the test piece is 4.85MPa for 7 days, and the strength for 28 days is 13.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com