Grouting air cushion plug

An air cushion and grouting technology, which is used in soil protection, wellbore/well components, earth-moving drilling, etc., can solve problems such as poor effect, affect the quality of the foundation, and grouting, and achieve the effect of ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

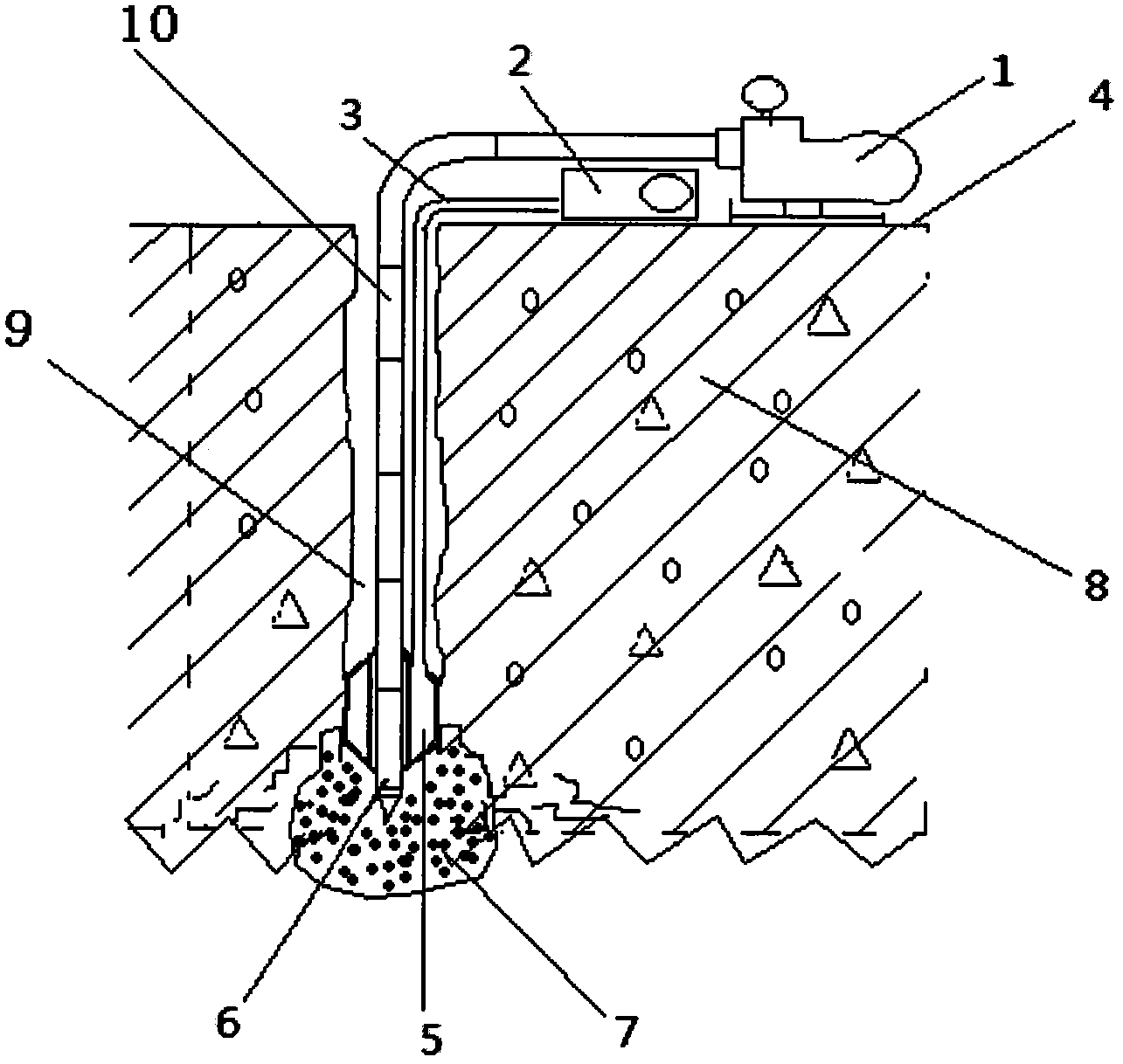

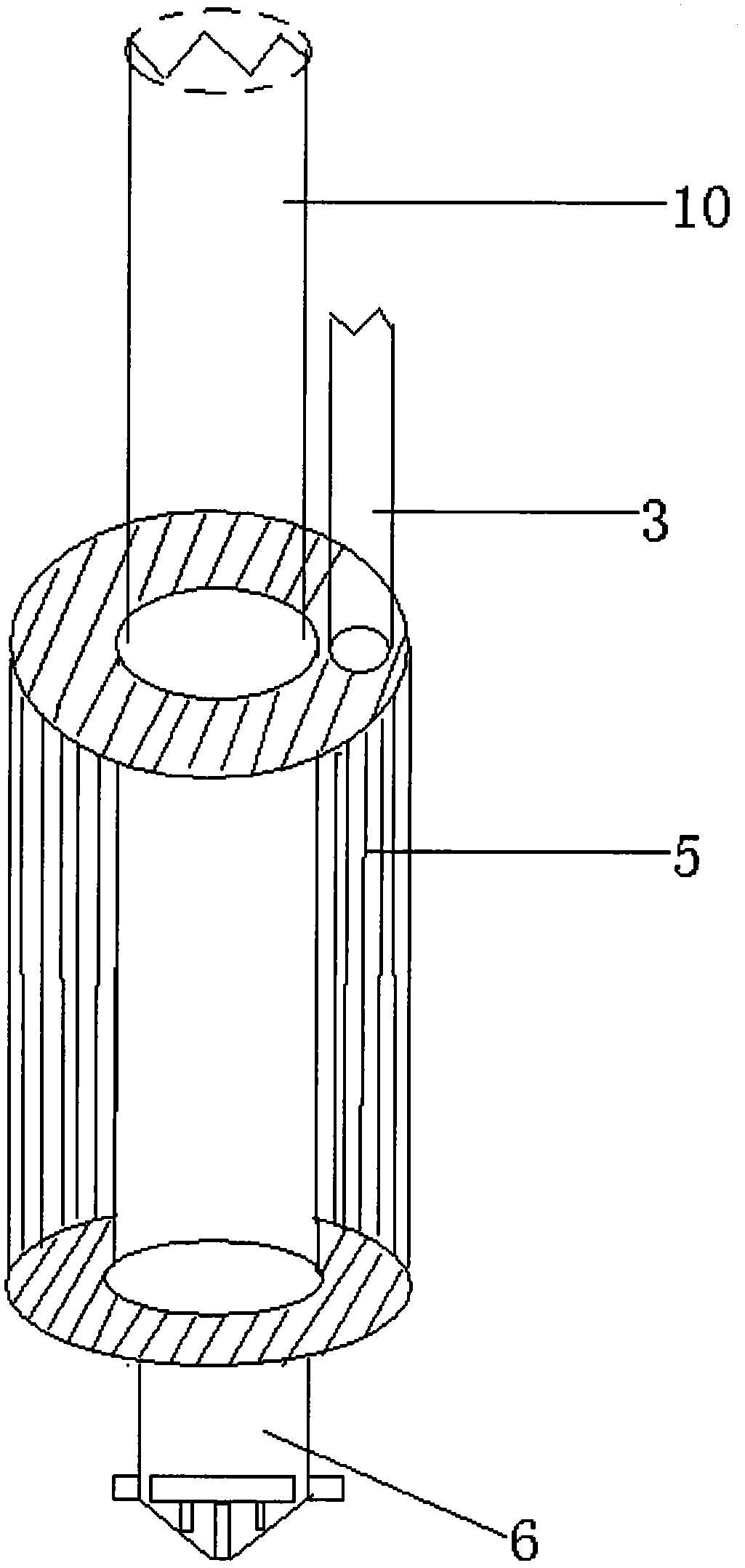

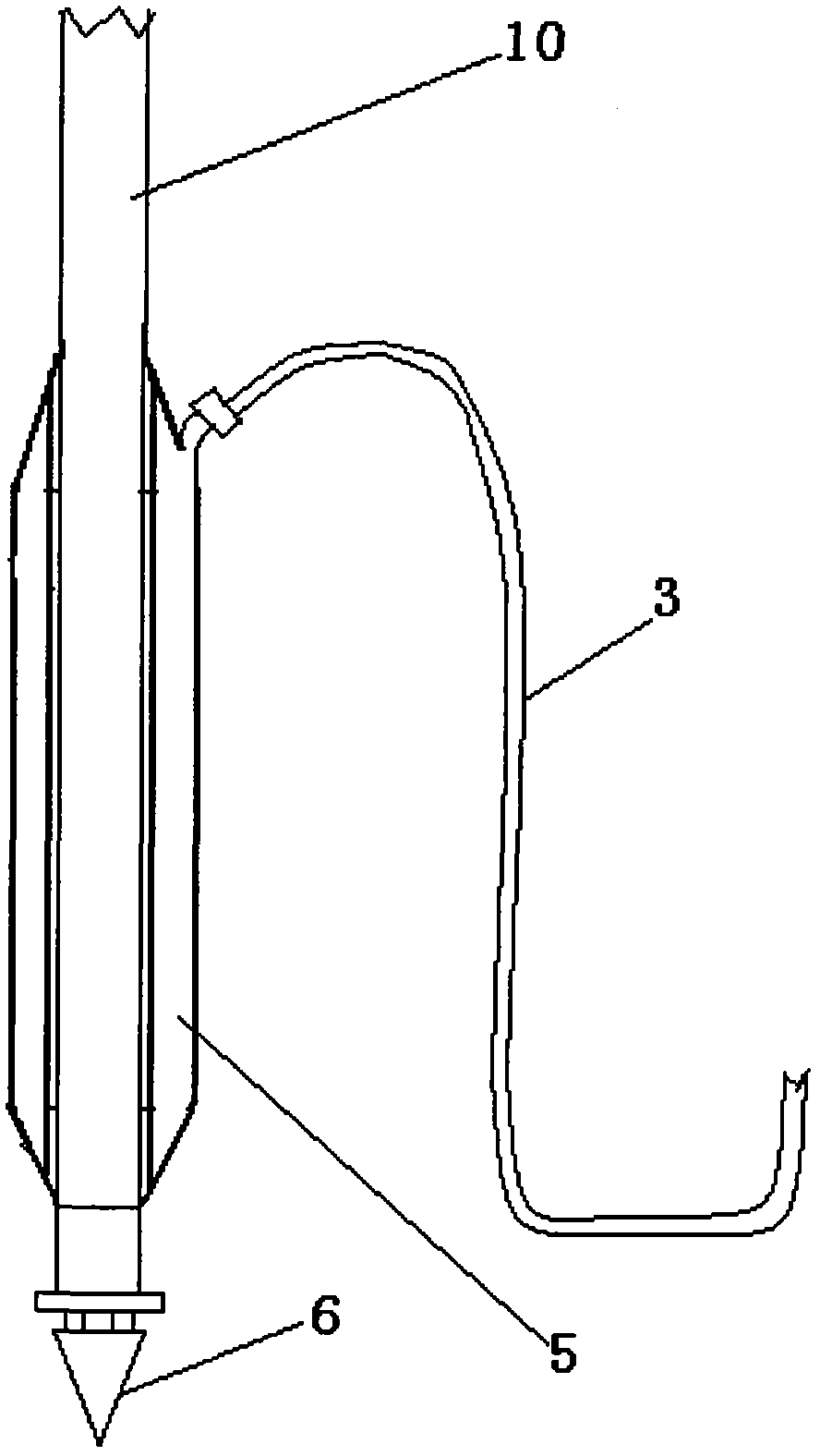

[0012] exist figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, be provided with grouting pump (1), air compressor (2), air pipe (3), ground (4), air cushion sealing plug (5), spray head (6), grout (7) ), formation (8), hole (9), slurry pipe (10).

[0013] Implement the grouting air cushion plug of the present invention, comprise ground (4) and formation (8), ground (4) right side fixes grouting pump (1), and grouting pump (1) connects grouting pipe (10), grouting Pipe (10) is installed in the hole (9), and hole (9) is placed in the middle of formation (8), and the bottom of slurry delivery pipe (10) is connected with spray head (6), and below spray head (6) is cement slurry ( 7), there is an air cushion sealing plug (5) around the pipe wall at the junction of the spray head (6) and the slurry delivery pipe (10), and the top surface of the air cushion sealing plug (5) is fixedly connected to the air pipe (3), the air pipe (3) The air compressor (2) is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com