Automatic adjustment deceleration strip with vehicle speed identification function

A technology of automatic adjustment and speed bumps, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of reducing the vibration of low-speed vehicles, excessive spring requirements, and high spring load, so as to slow down rapid deformation and increase vehicle weight. The effect of increasing the range and deceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

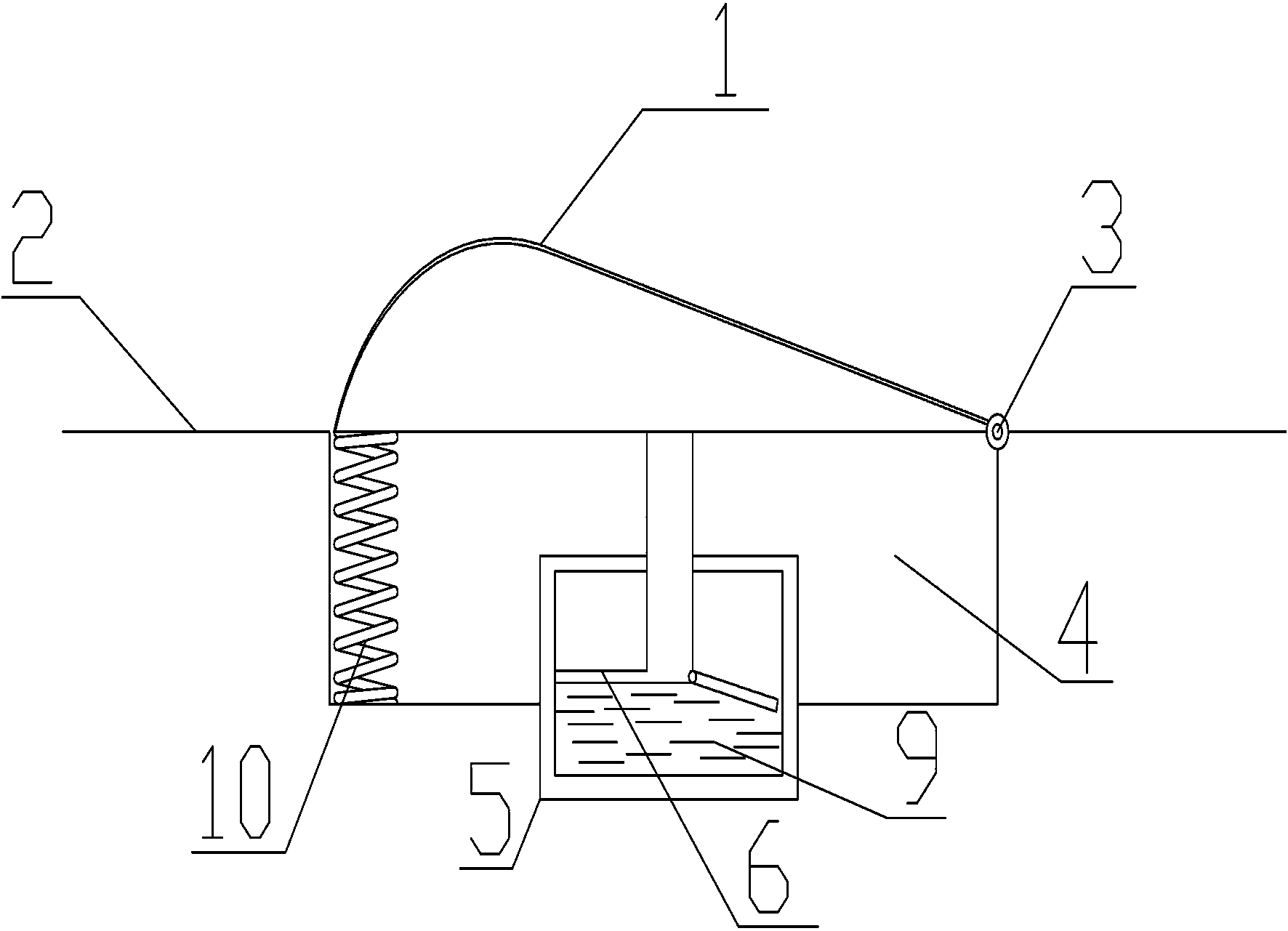

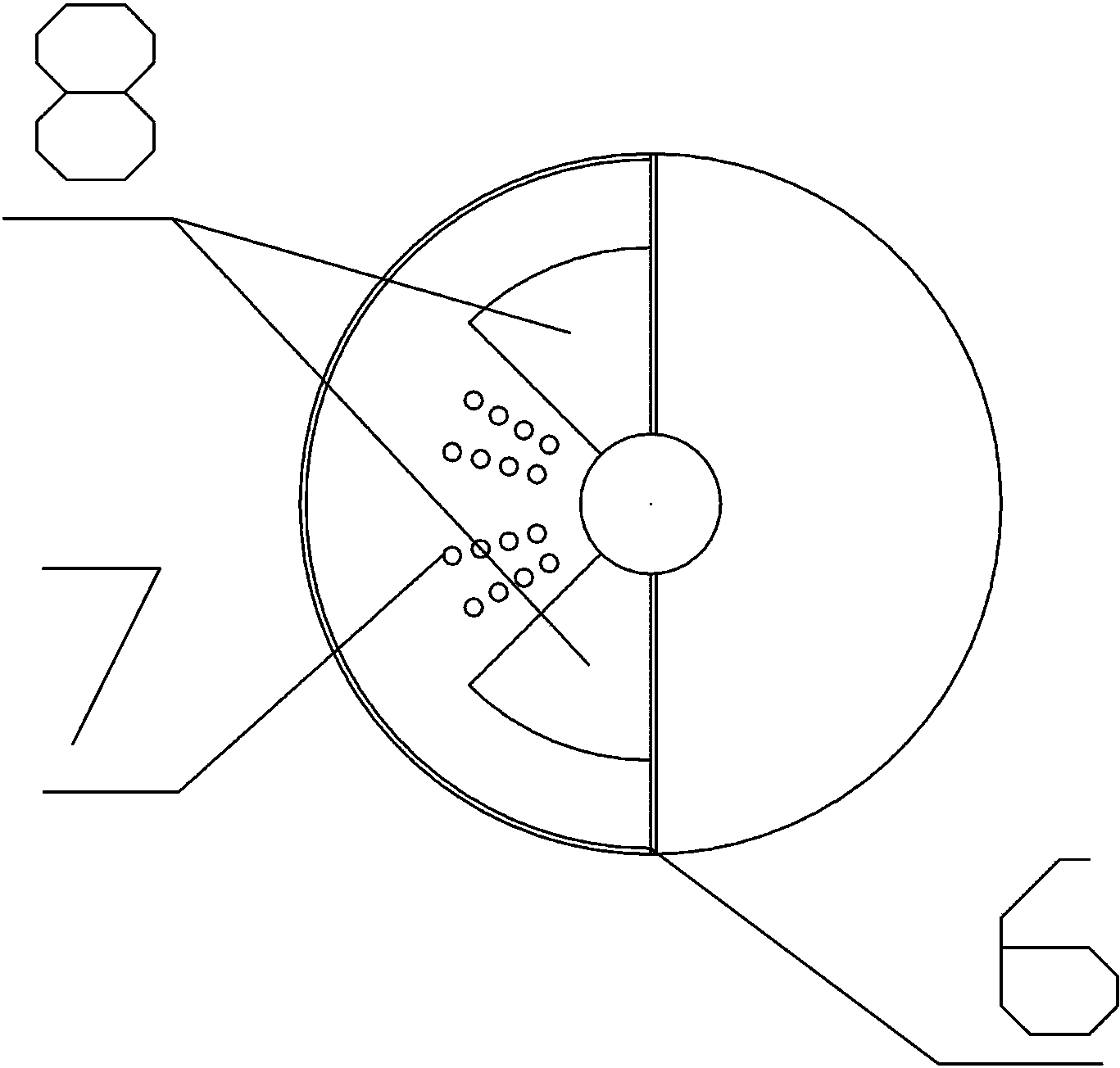

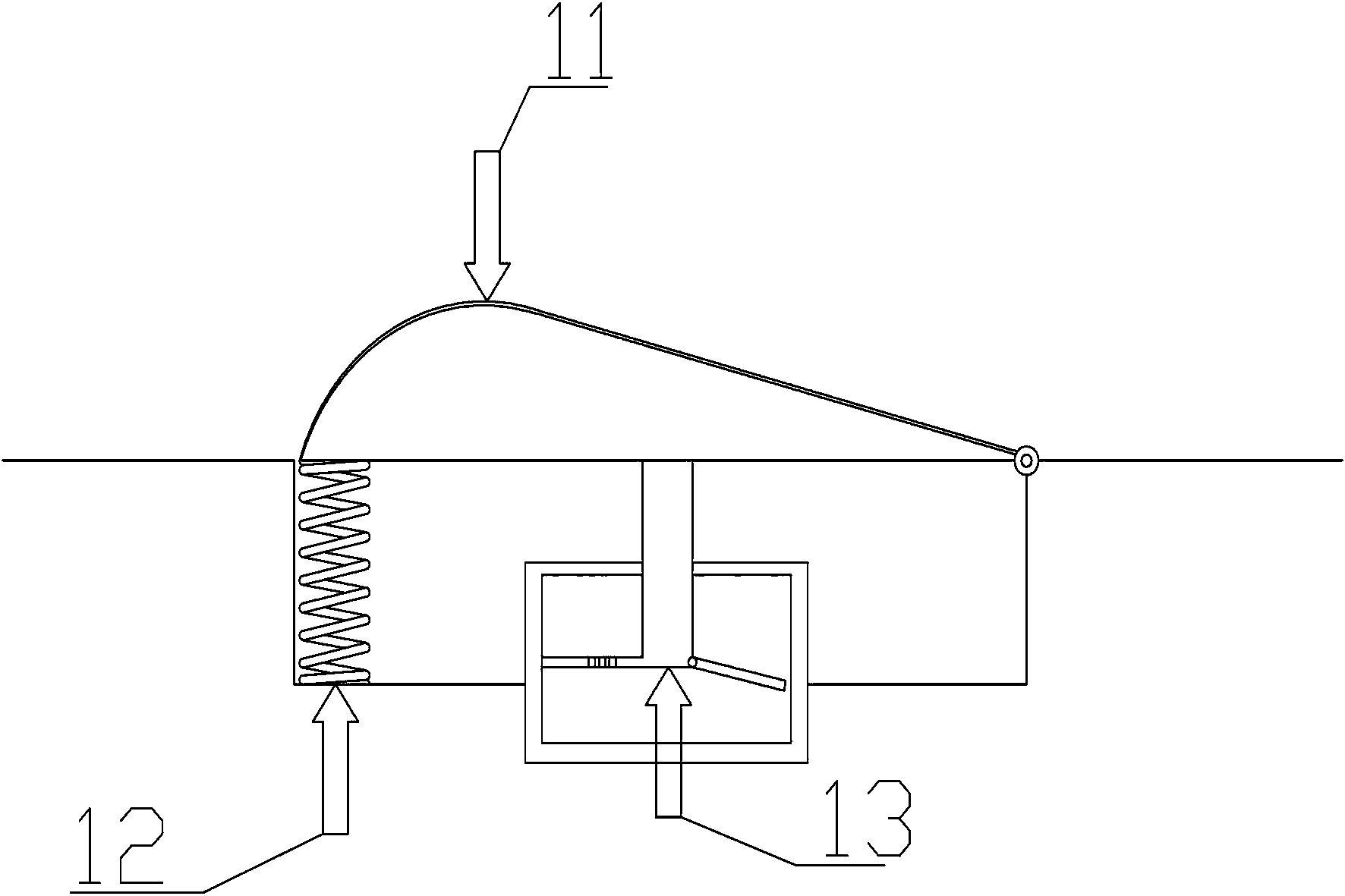

[0022] As shown in Figures 1 and 2, an automatic speed reduction belt with recognized vehicle speed includes a speed reduction belt panel 1, a sticky cylinder 5, and a piston plate 6; one end of the speed reduction belt panel 1 is fixed on the ground 2 through a shaft 3, and the other end is passed through The elastic part is in contact with the bottom surface of the concave 4 of the ground 2, the elastic part is a spring 10, a connecting rod is fixed on the speed bump panel 1, the cross section of the speed bump panel 1 is a parabolic turning line, and the non-fixed end of the connecting rod is provided with a piston The plate 6 and the piston plate 6 are provided with a permeable hole 7, and the piston plate 6 is movable and fixed with a permeable hole adjustment plate 8, which can cover the permeable hole 7 by rotating the permeable hole adjustment plate 8; the sticky cylinder 5 is fixed in the groove on the ground, The sticky cylinder 5 is equipped with a liquid 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com