Method and device for reducing running roughness in an internal combustion engine

An internal combustion engine, stability technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problem of increased running instability, and achieve the effect of good running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

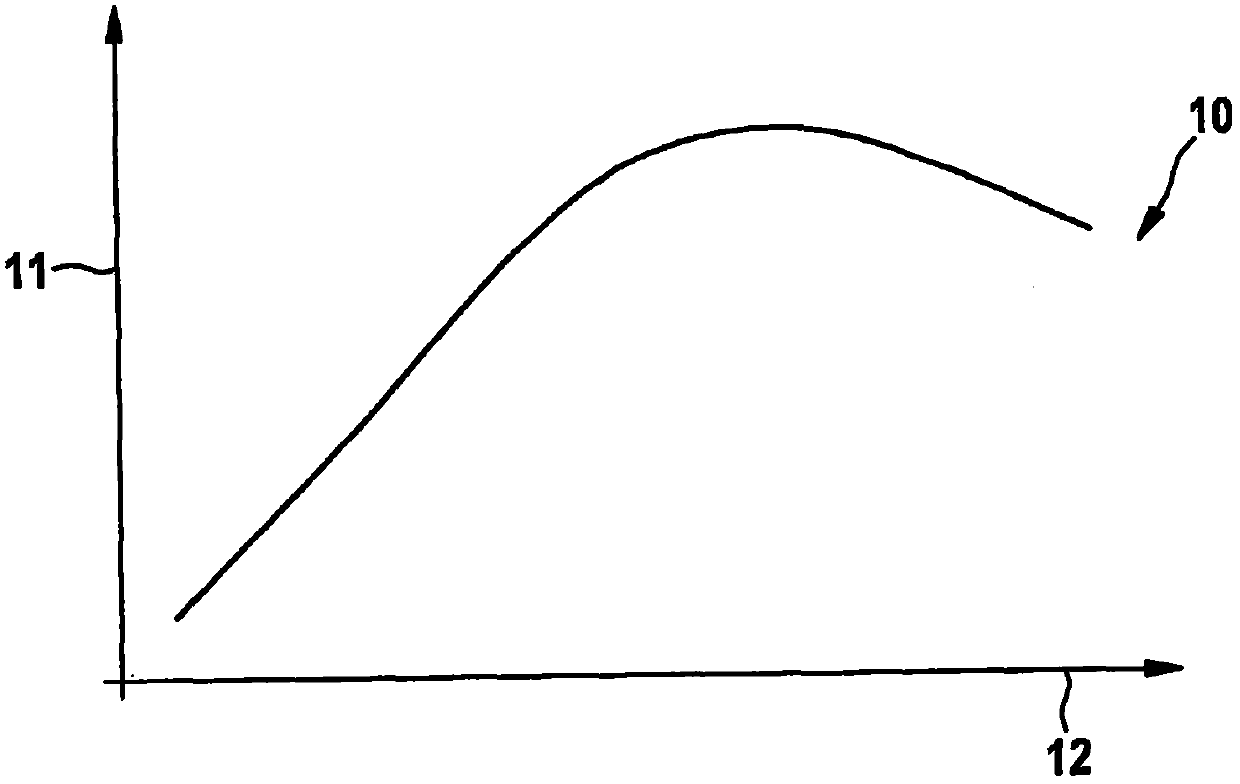

[0038] figure 1 The dependence of the torque 11 on the ignition angle 12 for a constant lambda value 13 is shown schematically in a first flow diagram 10 .

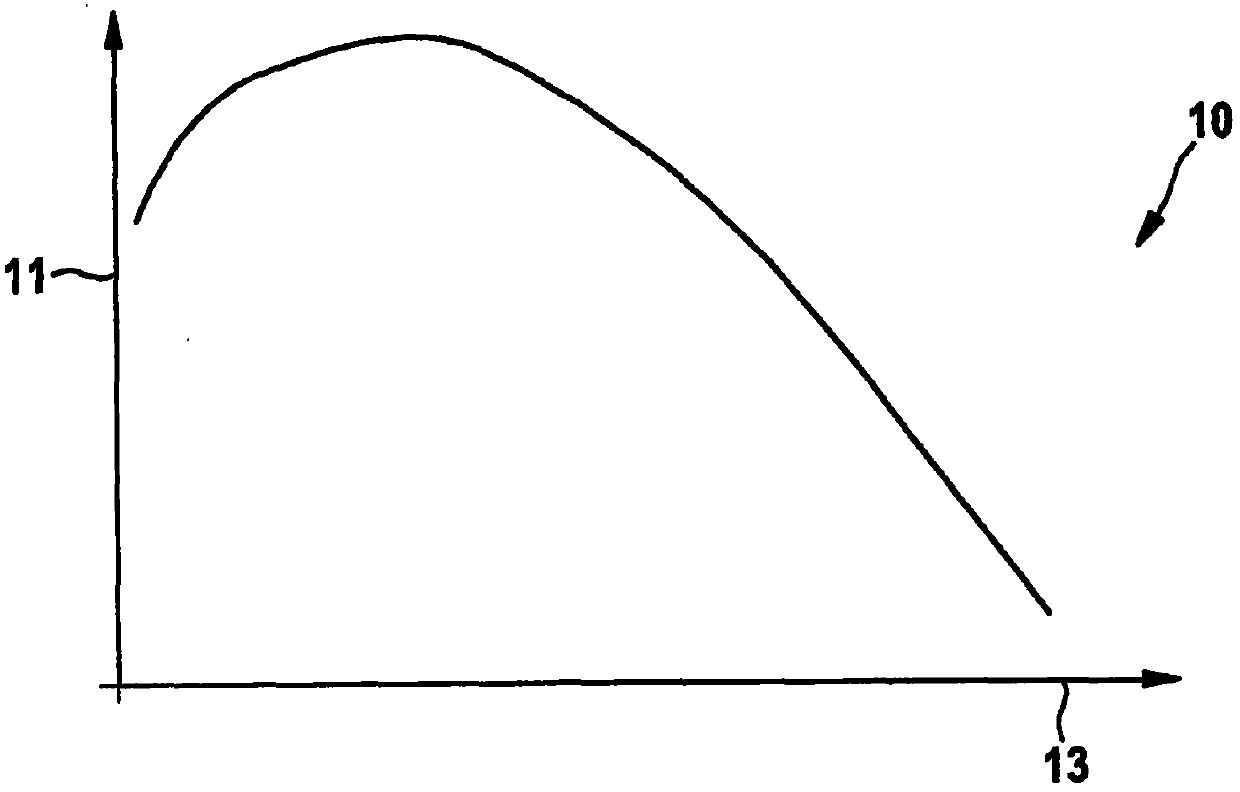

[0039] exist figure 2 The torque 11 as a function of the lambda value 13 for a constant ignition angle 12 is shown schematically in the second flow diagram 10 .

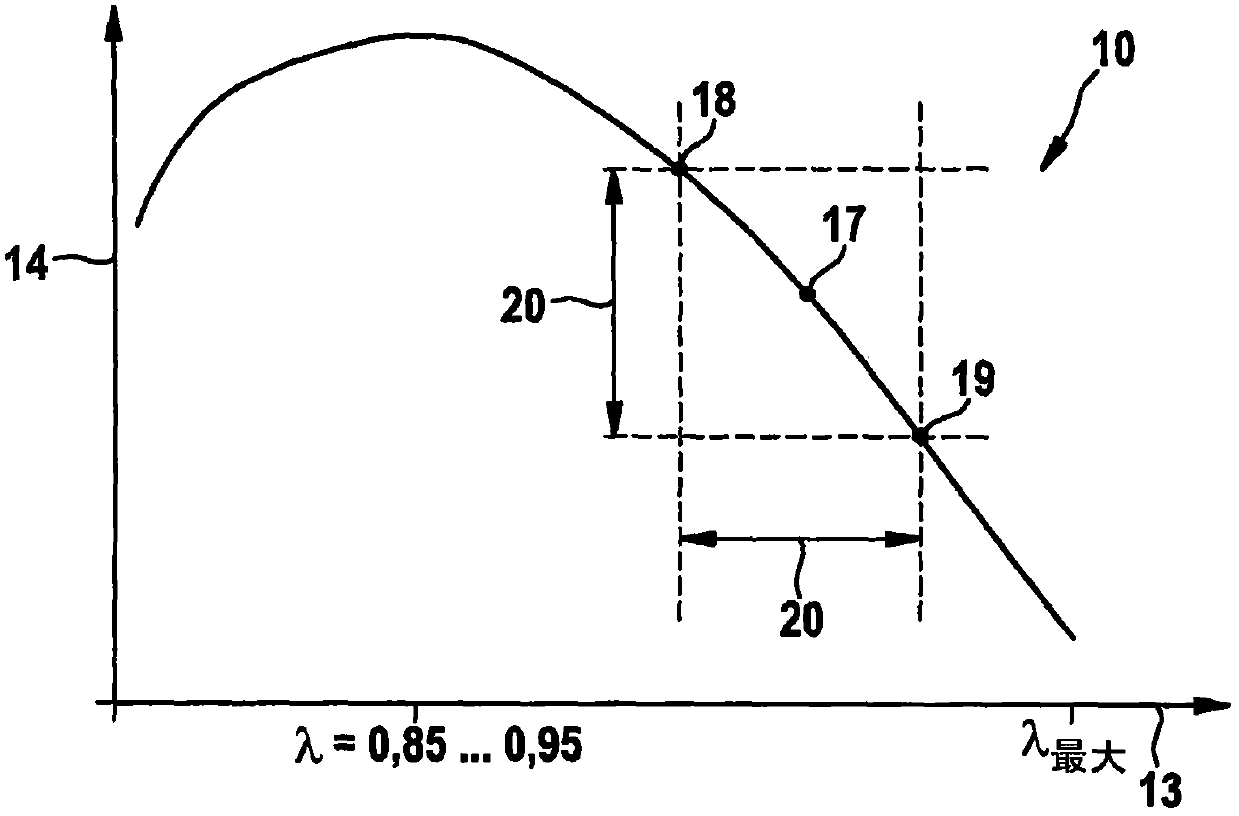

[0040] The speed-dependent function for lambda regulation utilizes the relationship between the generated torque 11(T) and the injected fuel quantity and the ignition angle 12 or the resulting position of the combustion center of gravity, which is injected The fuel quantity corresponds to a lambda value 13 . Since, in addition to the lambda value 13 and the ignition angle 12, the rotational speed and the actual air quantity also have an influence on the generated torque 11, it is important to always use a constant operating point for different ignition angles 12 and / or for The resulting torques 11 for different lambda values 13 are compared.

[0041] By c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com