Extruder screw

A screw and screw technology, applied in the field of extruders, can solve the problems that need to be further improved, and achieve the effect of maximizing torque, ensuring strength and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

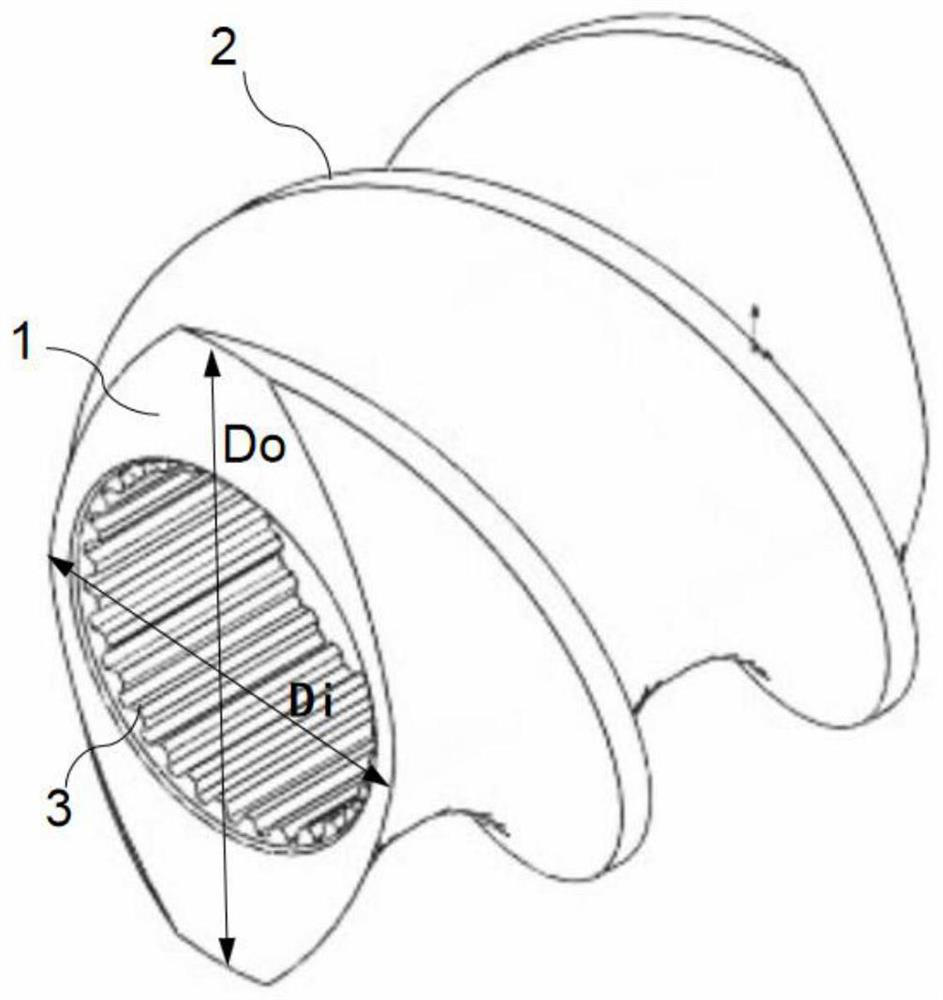

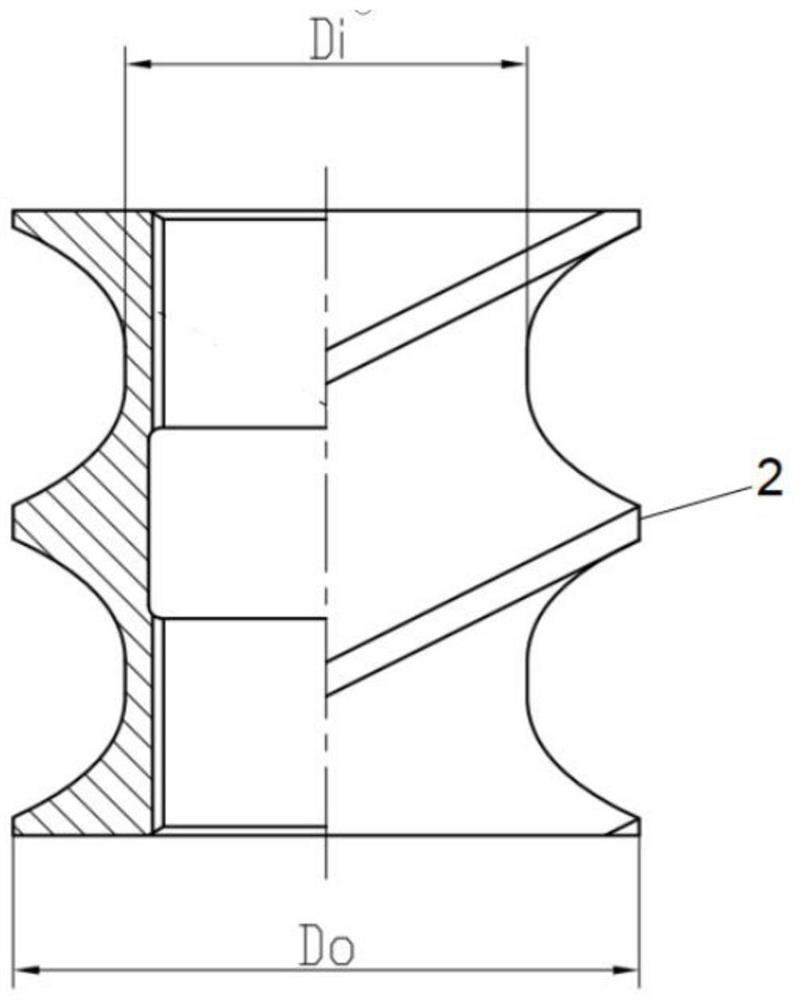

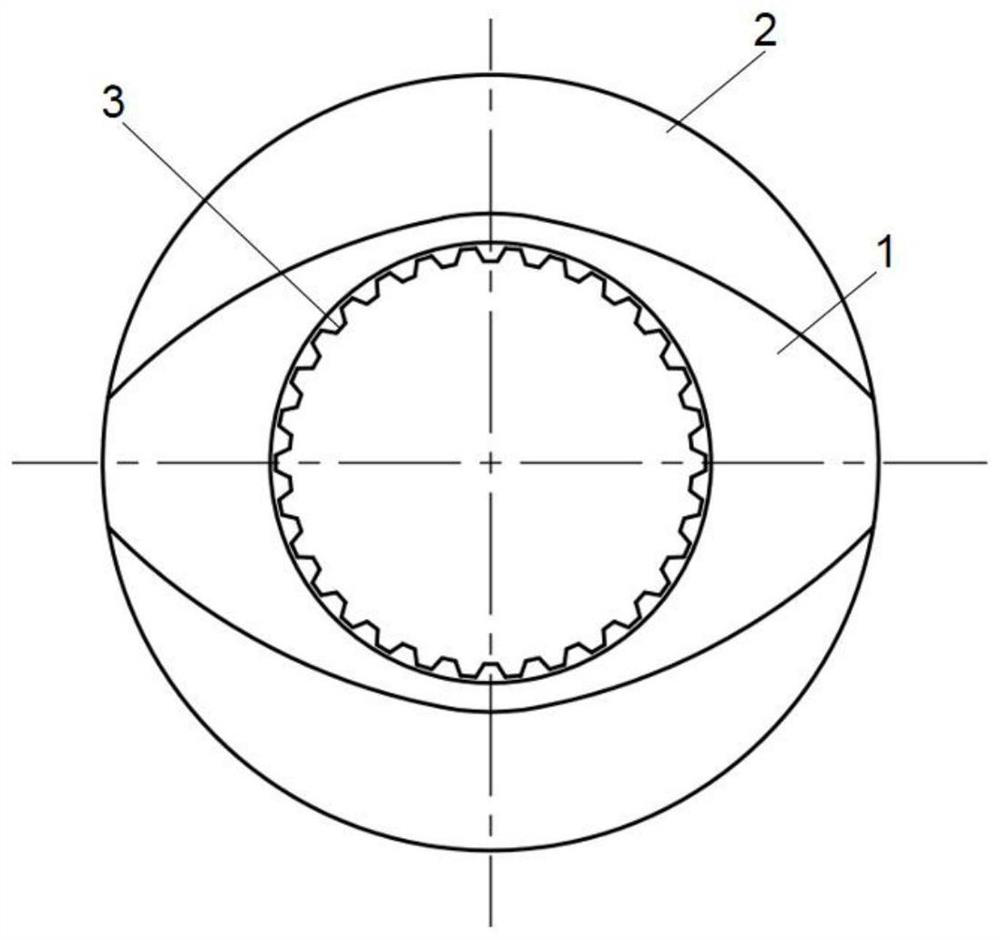

[0022] see Figure 1 to Figure 4 , an extruder screw, comprising a screw 1, the cross section of the screw 1 is oval; The central point is coincident, and the diameter of the spiral fin 2 is the same as the major diameter Do of the ellipse; the ratio of the major diameter Do of the ellipse to the minor diameter Di of the ellipse is 1.5 to 1.7; the screw rod 1 is Hollow structure, the screw 1 is provided with an internal spline 3, the pressure angle of the internal spline 3 is 25 to 35 degrees; and the screw 1 is provided with a spline shaft 4 matching the internal spline 3 for driving the screw 1 rotation. By controlling the ratio of the large diameter Do to the small diameter Di and the pressure angle of the screw, the diameter-volume ratio and torque of the screw extrusion can be maximized, thereby improving the extrusion efficiency and ensuring the strength of the internal spline; the spiral fin 2. The screw 1 and the internal spline 3 are integrally formed; the ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com