Variable force transmission mechanism

A technology of transmission mechanism and structural rod, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of excessive rigidity, complicated manufacturing process and small starting torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

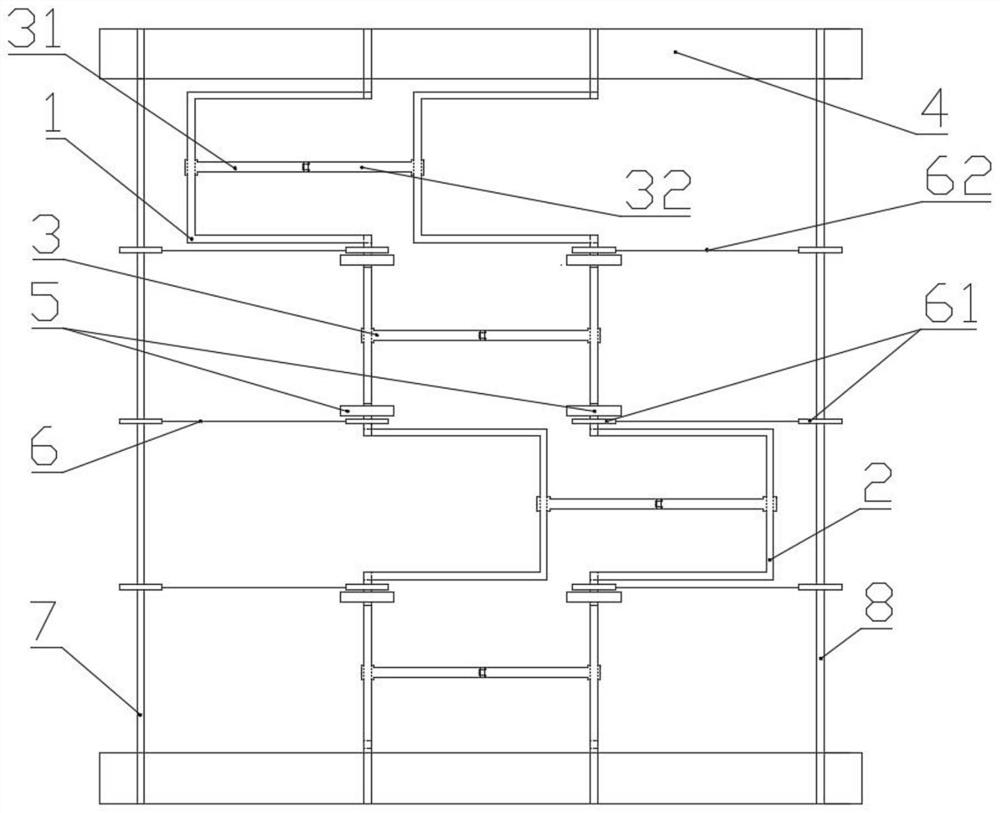

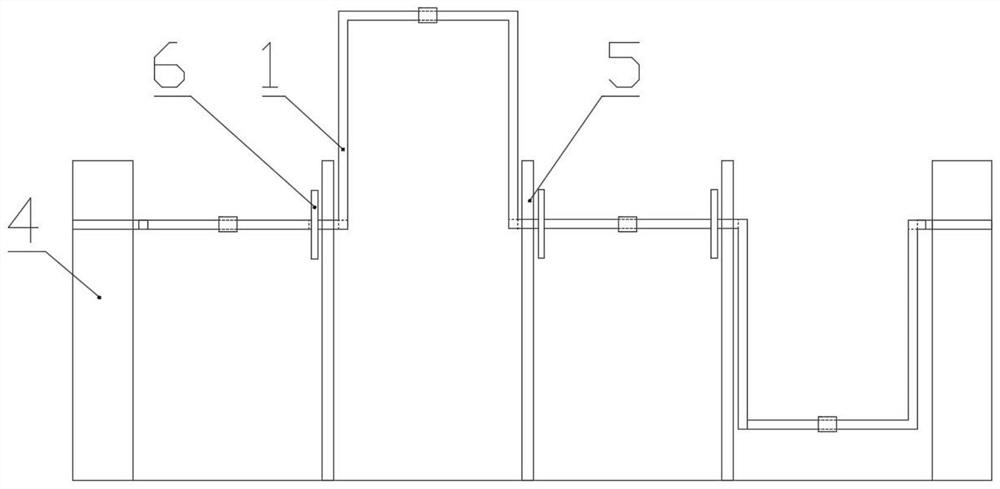

[0034] Embodiment 1: as Figure 1-2 As shown, an embodiment of a variable force transmission mechanism disclosed in the present invention includes:

[0035] The first crank rod 1, the second crank rod 2, the connection structure 3, the base frame 4 and the support frame 5;

[0036] The base frame 4 comprises two relatively parallel outer supports;

[0037] Both the first crank rod 1 and the second crank rod 2 are formed by connecting a plurality of bent structural rods sequentially end to end, and adjacent bent structural rods are evenly connected in a clockwise or counterclockwise direction, and the inclination angle is 360° divided by number, the connection between multiple bending structures is provided with a support frame 5, and the first crank rod 1 and the second crank rod 2 pass through the through holes at the upper ends of a plurality of support frames 5, and are rotatably connected with the support frame 5 ;

[0038] The head end and the tail end of the first cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com