Pressure filter and pressing filtering method thereof

A filter press and filter plate technology, applied in the field of filter press solid-liquid separation equipment, can solve the problems of insufficient work efficiency, material leakage, and no connection parts, etc., and achieve low equipment maintenance workload, high work efficiency, and high filtration efficiency. good water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

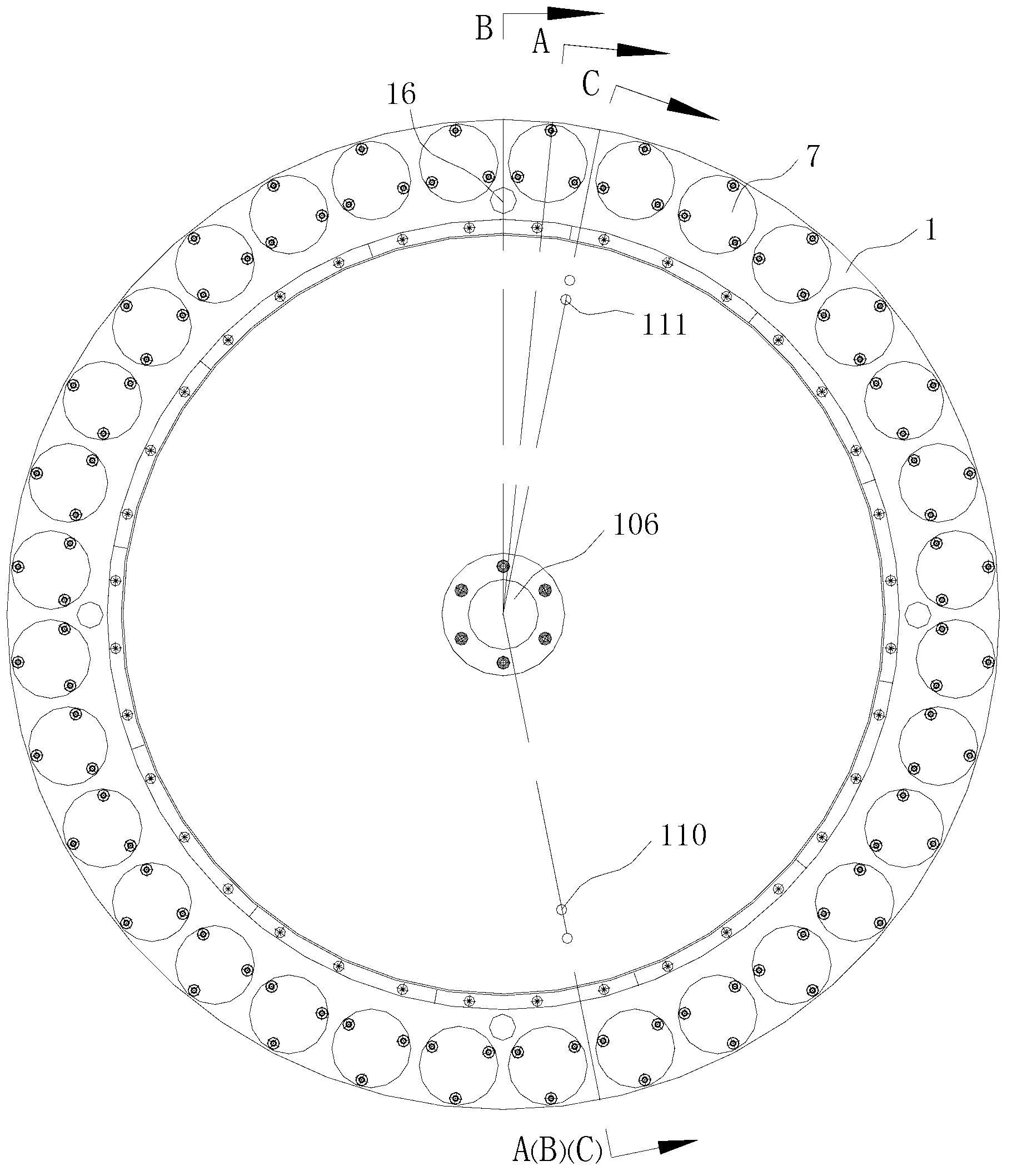

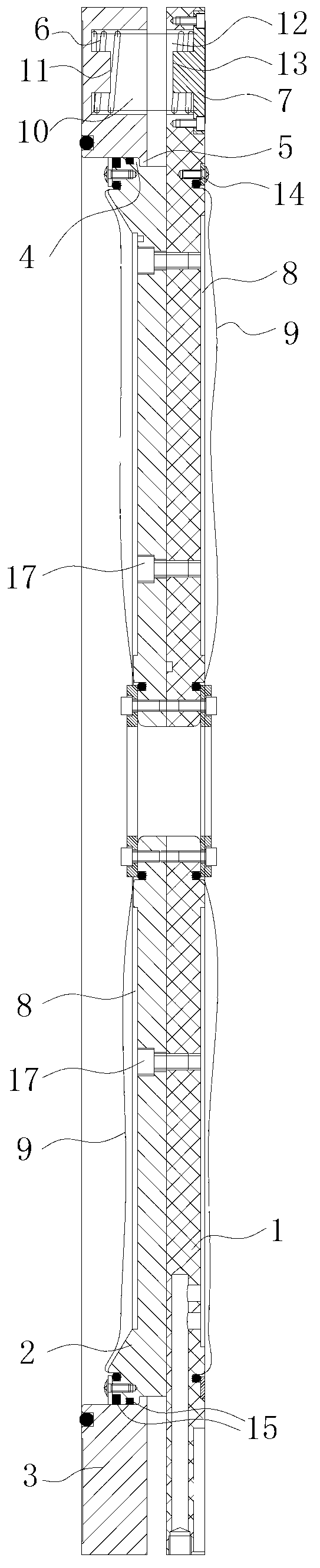

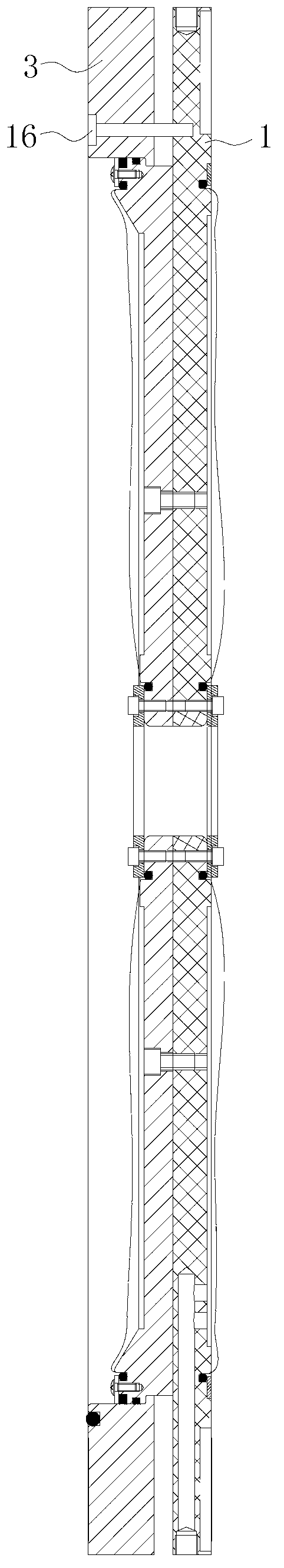

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0040] A filter press, including several filter plate groups connected in sequence, each filter plate group includes a main board, a sub The plate and the sub-frame are located on the same side of the main board; the other side of the main board is set in contact with the sub-frame of the adjacent filter plate group, and there is a volume-variable space between the adjacent filter plate groups to accommodate the material to be filtered. In the filter press space, each filter plate group has a material channel, and the material channel is connected with the filter press space, and the material enters the filter press space through the material channel. In each filter plate group, the opposite side of the sub-plate and the main plate A filter screen is set, and the outside of the filter screen is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com