Garbage incinerator

A waste incinerator and furnace body technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of wasting resources, wasting resources, occupying land, etc., to prevent the generation of harmful gases, improve the combustion rate, and occupy land small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

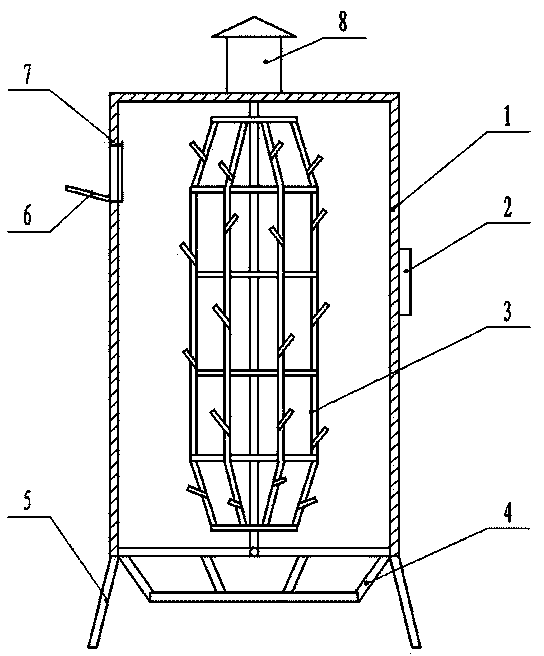

[0024] A garbage incinerator comprises a furnace body 1, a combustion chamber, a feed slot 6, a movable baffle 7, a furnace bar 4, a chimney 8 and a furnace foot 5. The inner wall of the body of furnace 1 is provided with refractory bricks, the body of furnace 1 is hollow to form a combustion chamber, and the top of the body of furnace 1 is provided with a chimney 8 whose diameter is 1 / 5 of the diameter of the body of furnace 1 . The upper part of the furnace body 1 is provided with a feeding notch 6 and a movable baffle 7, and the movable baffle (7) is a tile shape consistent with the arc shape of the furnace body 1 where it is located. ring, and is movably connected with the furnace body 1 above the feeding slot 6. The bottom of the furnace body 1 is provided with a furnace bar 4, and the bottom end of the furnace body 1 is opened to form an ash outlet; the bottom end of the furnace body 1 is provided with three furnace feet 5; The support 3, the support 3 is in the shape o...

Embodiment 2

[0027] A garbage incinerator comprises a furnace body 1, a combustion chamber, a feed slot 6, a movable baffle 7, a furnace bar 4, a chimney 8 and a furnace foot 5. The inner wall of the body of furnace 1 is provided with refractory bricks. The body of furnace 1 is hollow to form a combustion chamber. The top of the body of furnace 1 is provided with a chimney 8 whose diameter is 1 / 4 of that of the body of furnace 1 . The upper part of the furnace body 1 is provided with a feeding notch 6 and a movable baffle 7, and the movable baffle (7) is a tile shape consistent with the arc shape of the furnace body 1 where it is located. Hanging ring, and is movably connected with the furnace body 1 above the feeding slot 6. The middle section of the body of furnace 1 is provided with a charging door 2, and the charging door 2 is arranged on the other side corresponding to the feeding notch 6, so that it is convenient to throw in garbage at the same time. The bottom of the furnace body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com