Fault detection method for electric cooker

A fault detection and rice cooker technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as user burns, caliper components cannot be locked in place, etc., and achieve the effect of reducing safety hazards in use, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

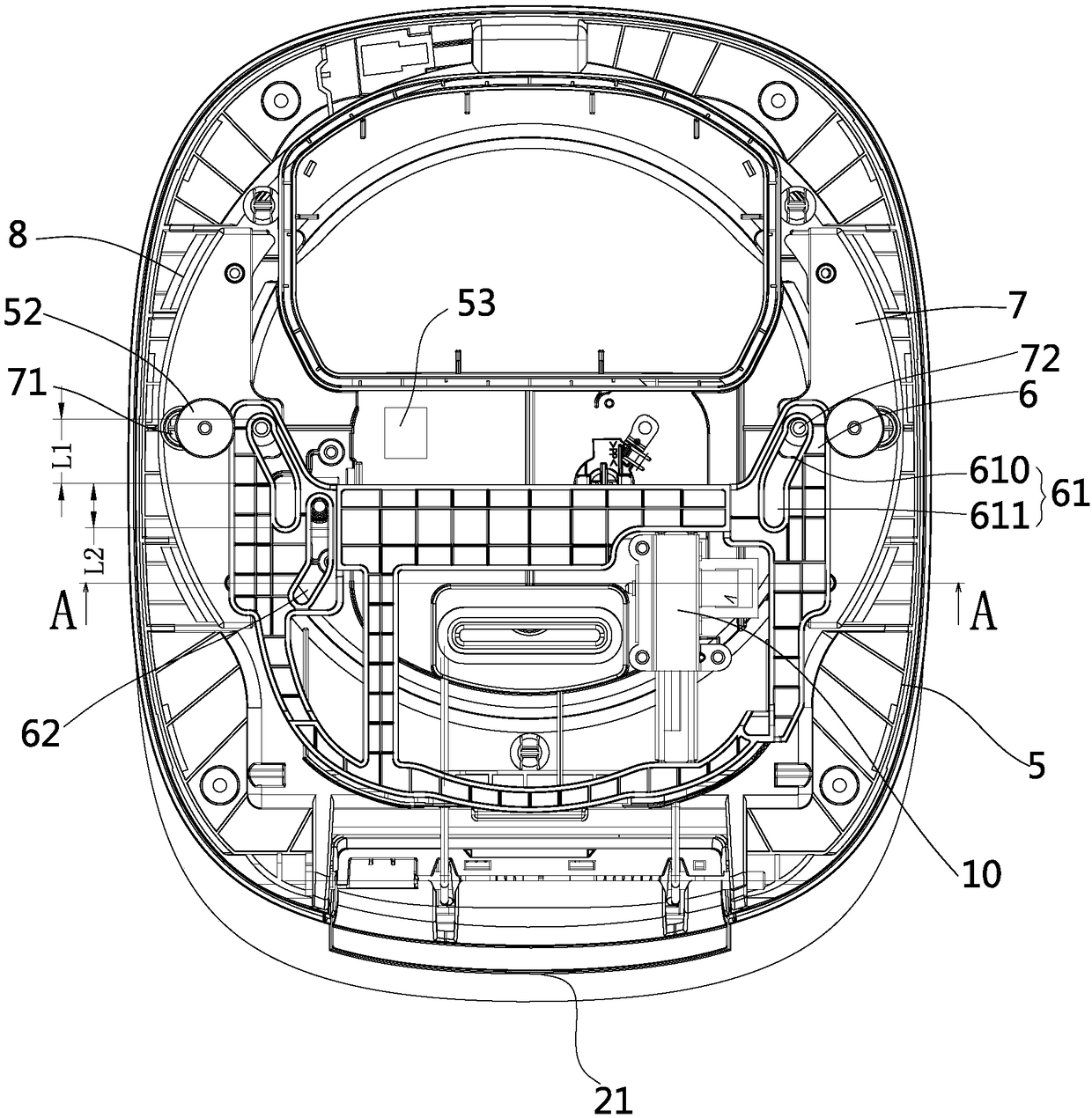

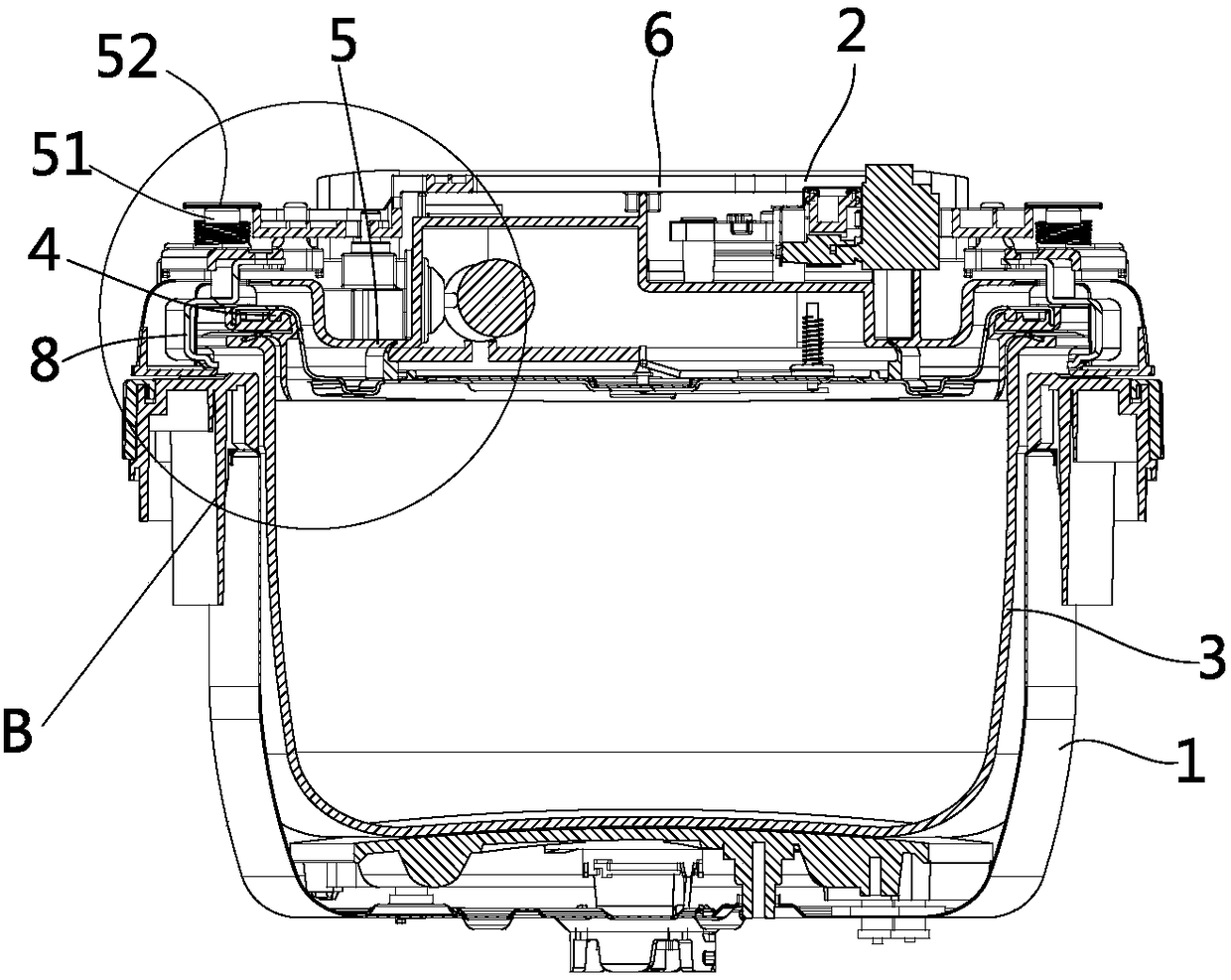

[0028] Such as Figure 1 to Figure 5 As shown, the electric rice cooker in this embodiment includes a pot body 1, a pot cover 2 and a main controller. One end of the pot cover 2 is hinged on the pot body 1. The pot body 1 is provided with an inner pot 3, and the pot cover 2 includes an outer lid. And the inner cover 4, the inner cover 4 and the inner pot 3 form a cooking cavity, the outer cover includes the upper cover and the inner lining 5, the inner lining 5 is installed between the inner cover 4 and the upper cover, and the inner cover 4 can be installed floating up and down. On the lining 5, there is a floating gap between the inner cover 4 and the inner lining 5.

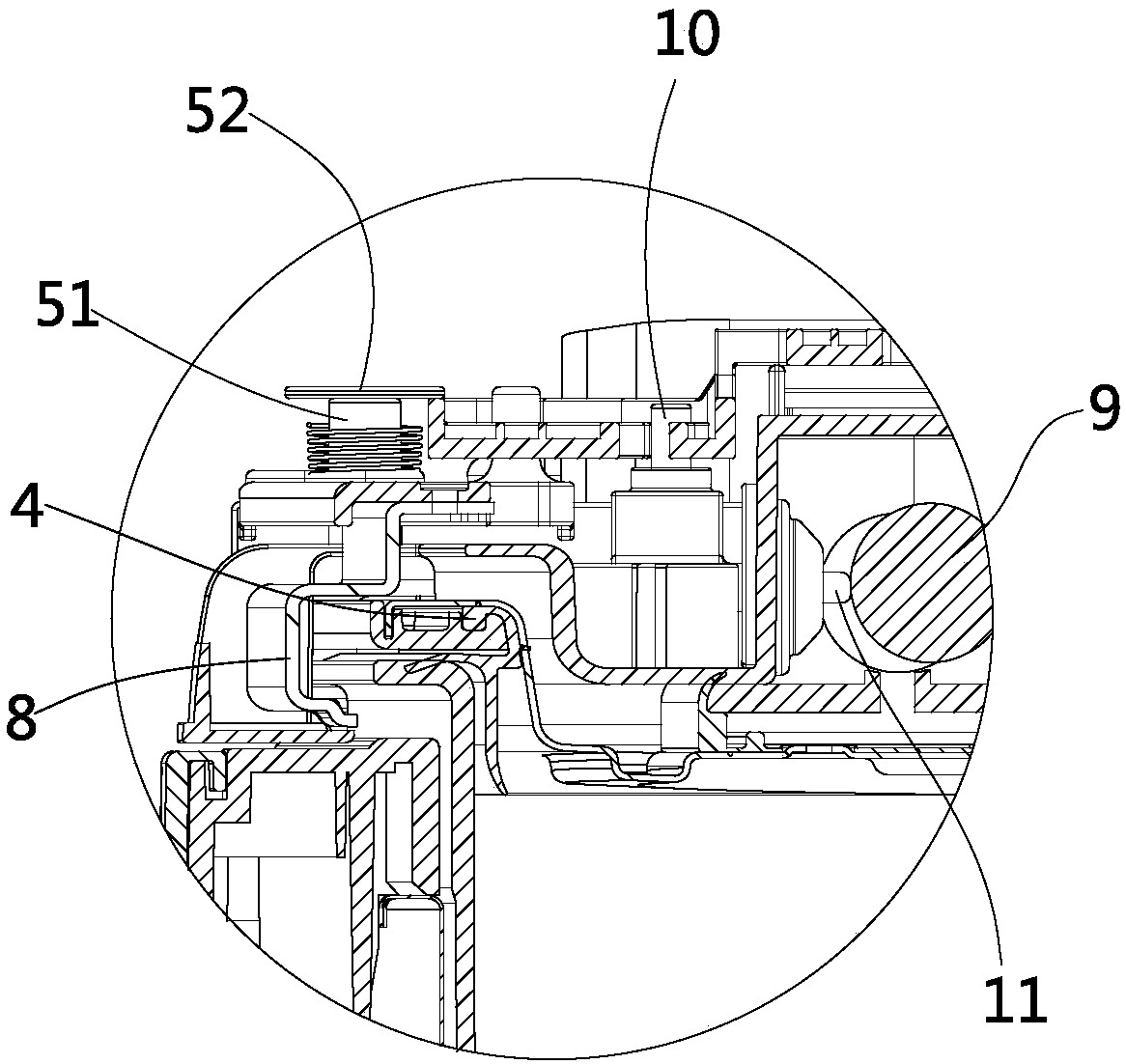

[0029] The inner liner 5 of this embodiment is equipped with a caliper assembly and a driving part. The driving part includes a sliding plate 6 and a driver. The driver is a motor 10. The caliper assembly includes a caliper bracket 7 and a caliper 8. The lower end of the caliper 8 is provided with a cover facing ...

Embodiment 2

[0042] Compared with the first embodiment, the micro switch in this embodiment is arranged on the inner lining 5, and the distance between the micro switch and the caliper 8 is the maximum radial inward movement of the caliper when the rice cooker is in an open state. When closing the cover, after the caliper assembly moves radially inward to the maximum distance, the caliper 8 is locked in place and triggers the micro switch. At this time, the main controller receives the first detection signal sent by the micro switch and judges that the caliper assembly is locked In place; if the radial inward movement of the caliper 8 is less than the maximum distance, the micro switch is in an untriggered state, and the main controller receives the second detection signal sent by the micro switch at this time, and determines that the caliper assembly is not locked in place, And the motor 10 fails, and the rice cooker is controlled to stop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com