Engine intake pipe water injection system

A technology of water spray system and air intake pipe, which is applied to engine components, machines/engines, charging systems, etc., can solve the problems of complex structure, unsolvable problems of water emulsion fuel phase separation, poor economy, etc., and achieves high control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

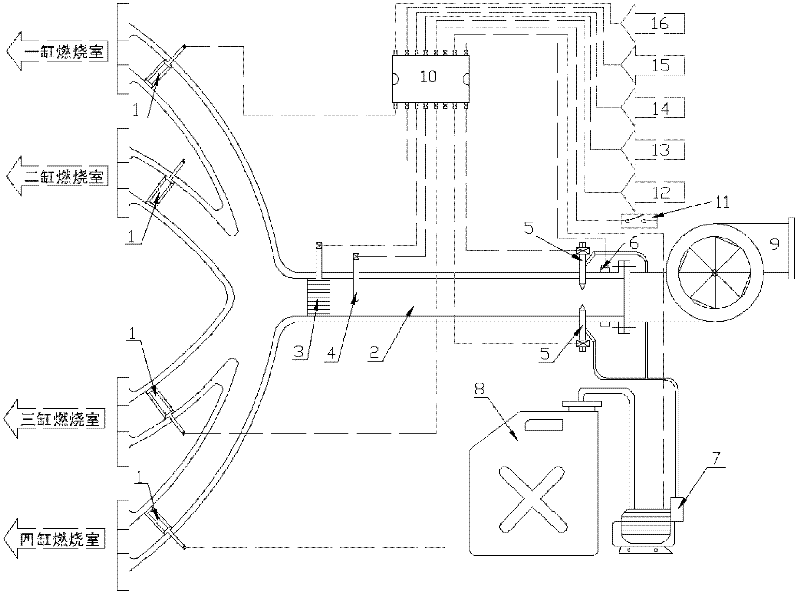

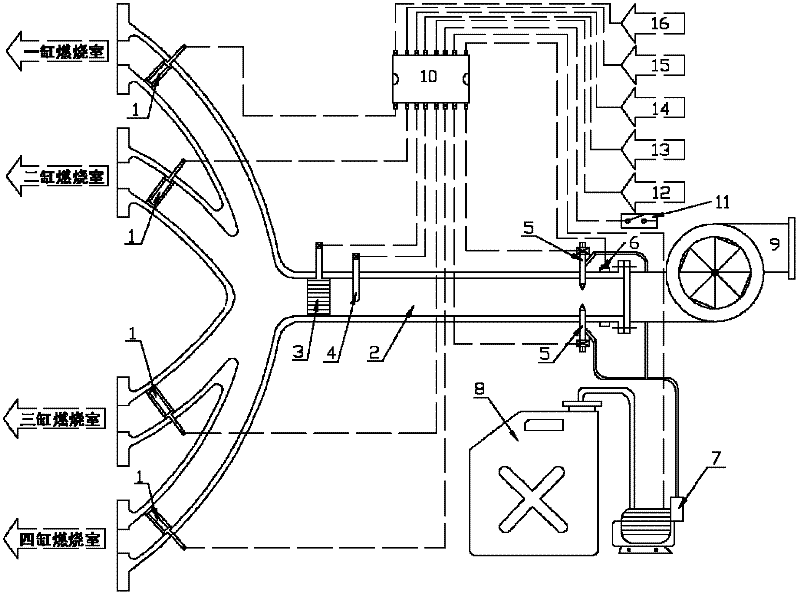

[0014] The system connection of the present invention is as follows: each intake manifold leading to the combustion chamber is provided with a convex evaporation zone 1, and the intake manifold 2 is sequentially provided with a grid type droplet evaporator 3, an intake air temperature sensor 4, an electromagnetic A high-pressure water atomizing nozzle 5 and an air intake flow sensor 6; the electromagnetic high-pressure water atomizing nozzle 5 is connected in series with a high-pressure water pump 7 and a water storage tank 8; The main control chip 10 in the water spray electronic control subsystem of the intake pipe is respectively connected to: the electromagnetic high-pressure water atomization nozzle 5, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com