Steam rotary drying system for ammonium salt and method for preparing ammonium salt

A technology of rotary drying and rotary drying machine, which is applied in the direction of drying solid materials, dry cargo handling, dry gas arrangement, etc., which can solve the problems of low heat utilization rate, high power consumption, high dust removal pressure, etc., to prolong the residence time, good The effect of sealing performance and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

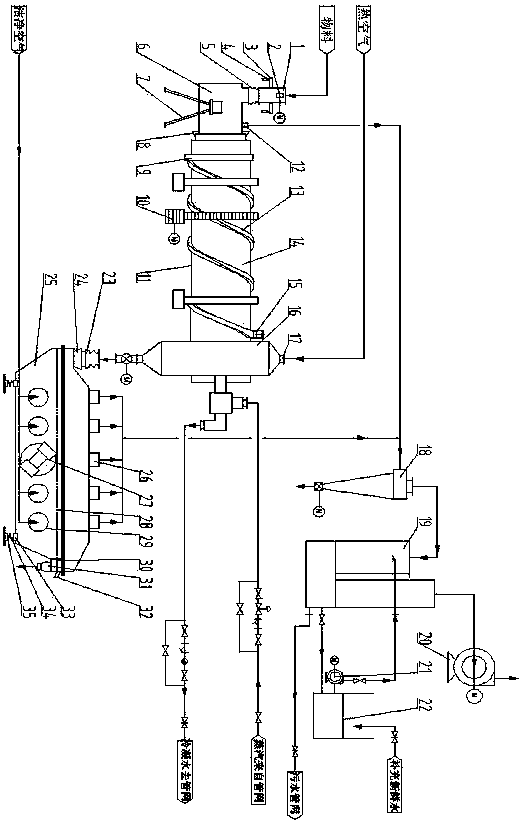

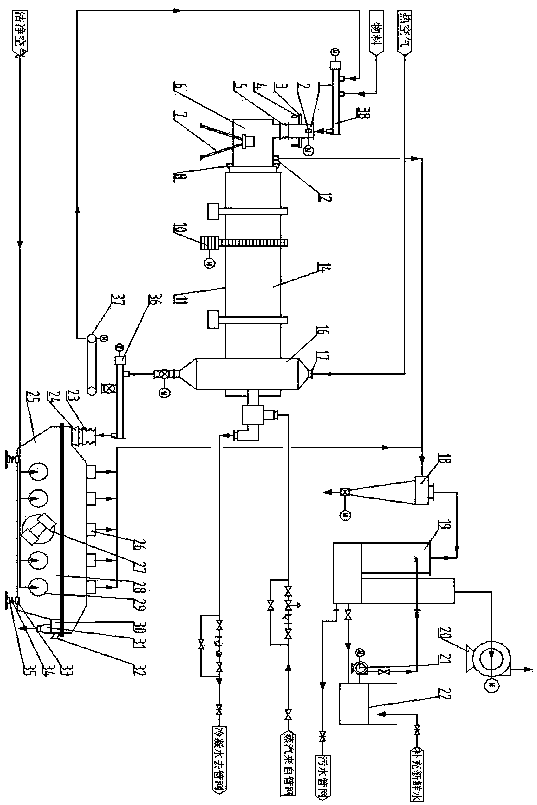

[0074] Embodiment one provided by the present invention: see appended figure 1 , a steam rotary drying system for ammonium salts, comprising a vibrating feeder 1, a soft connection 5 for feeding, a rotary steam dryer 14, a soft connection 23 for discharging, a vibrating conveying cooling and screening machine 25 and an exhaust dust removal device. The vibrating feeder 1, the feeding soft connection 5, the steam rotary dryer 14 and the tail gas dedusting device are connected in sequence, and the steam rotary dryer 14, the discharging soft connection 23 and the vibration conveying cooling and screening machine 25 are connected in sequence.

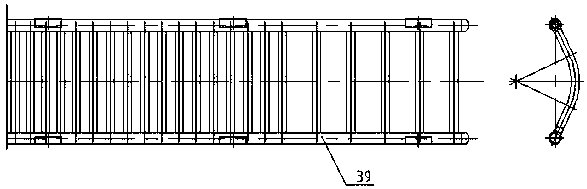

[0075] The steam rotary dryer 14 includes a feed cover 6, a rotary drum 11, a discharge cover 16, a transmission device 10 and some heat exchange tubes in the rotary drum, with figure 1 The left end of the steam rotary dryer 14 shown in the figure is the feed end, and the right end is the discharge end. The feed cover 6 is arranged at the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com