Patents

Literature

31results about How to "Increase friction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

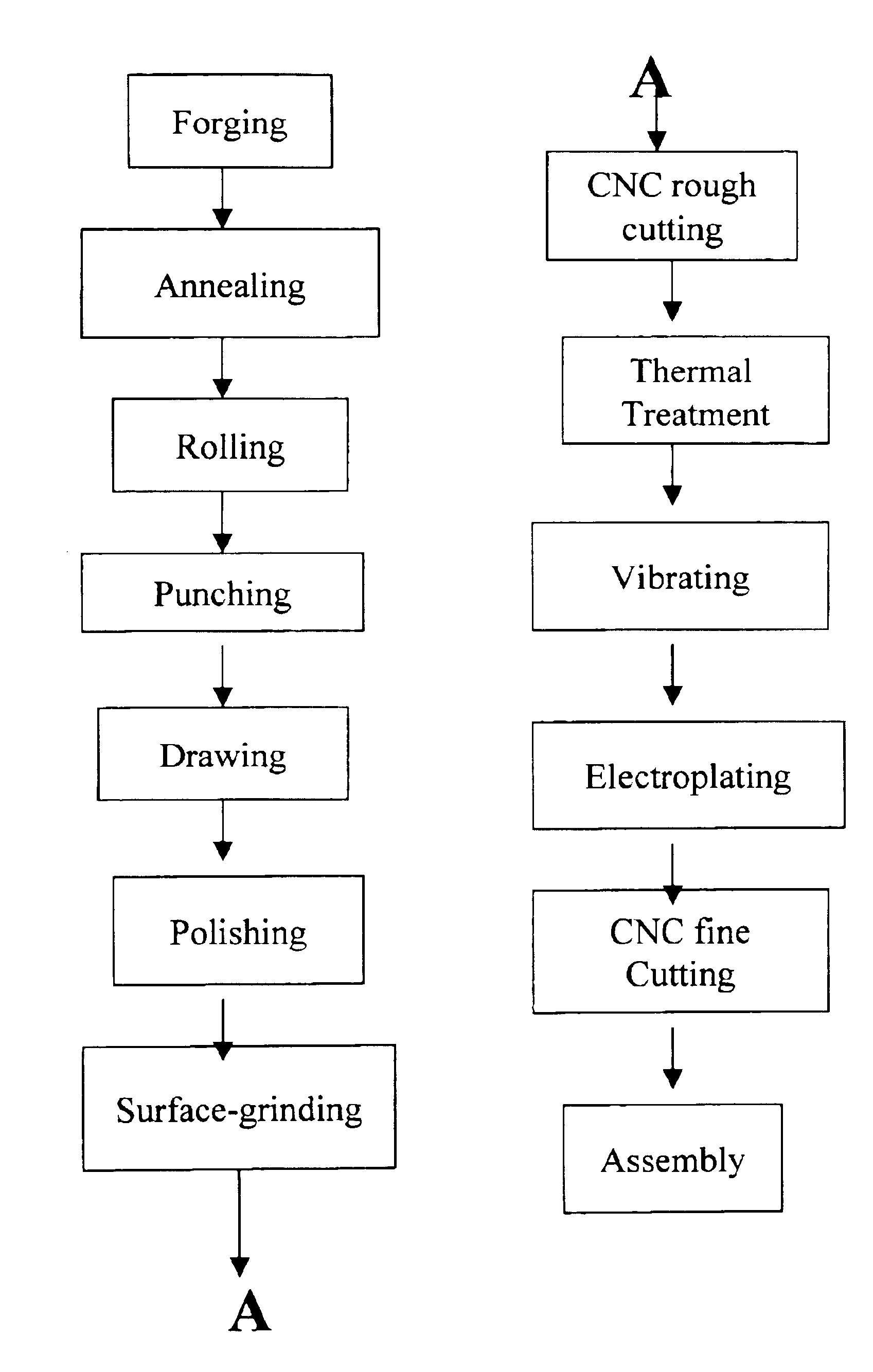

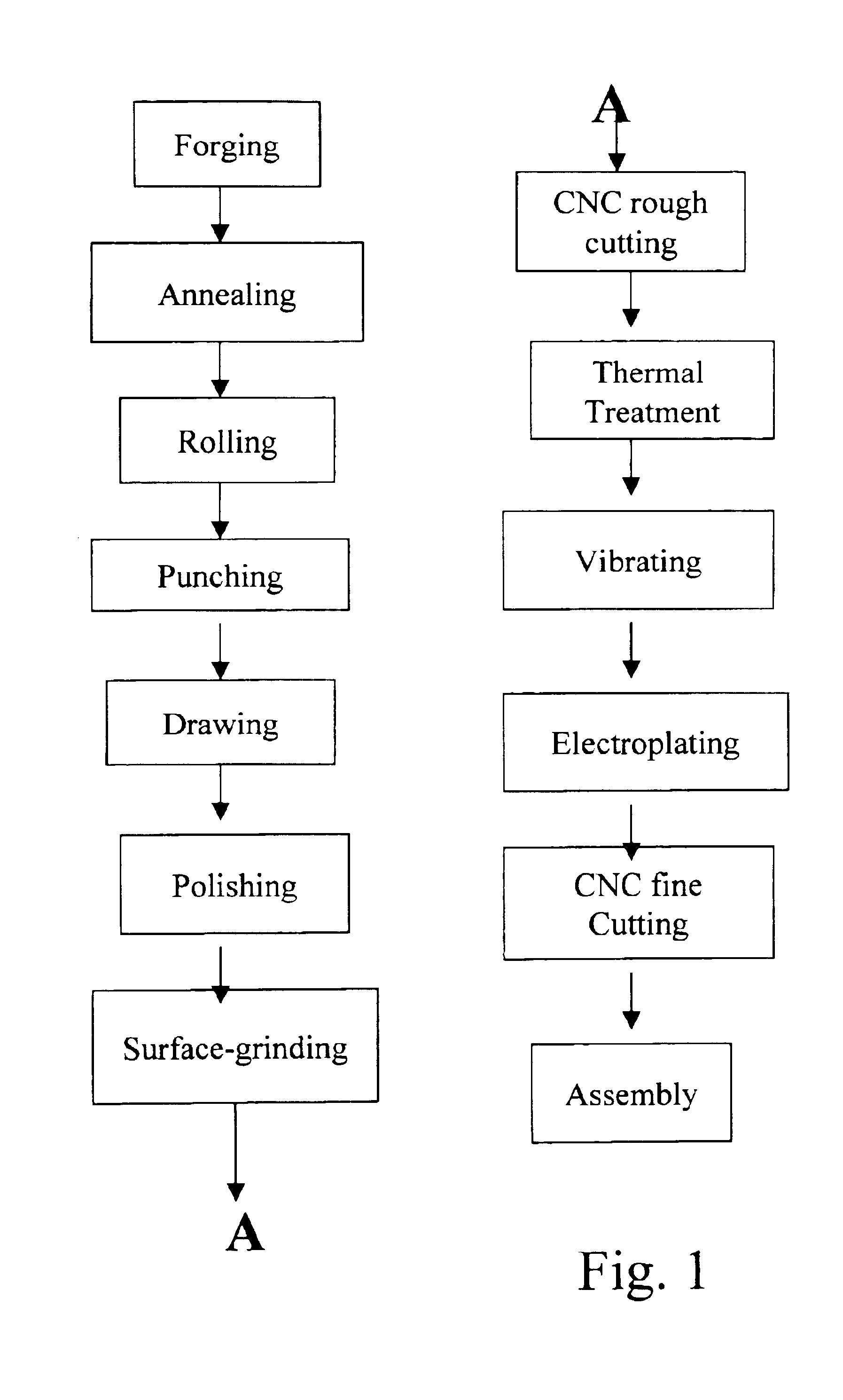

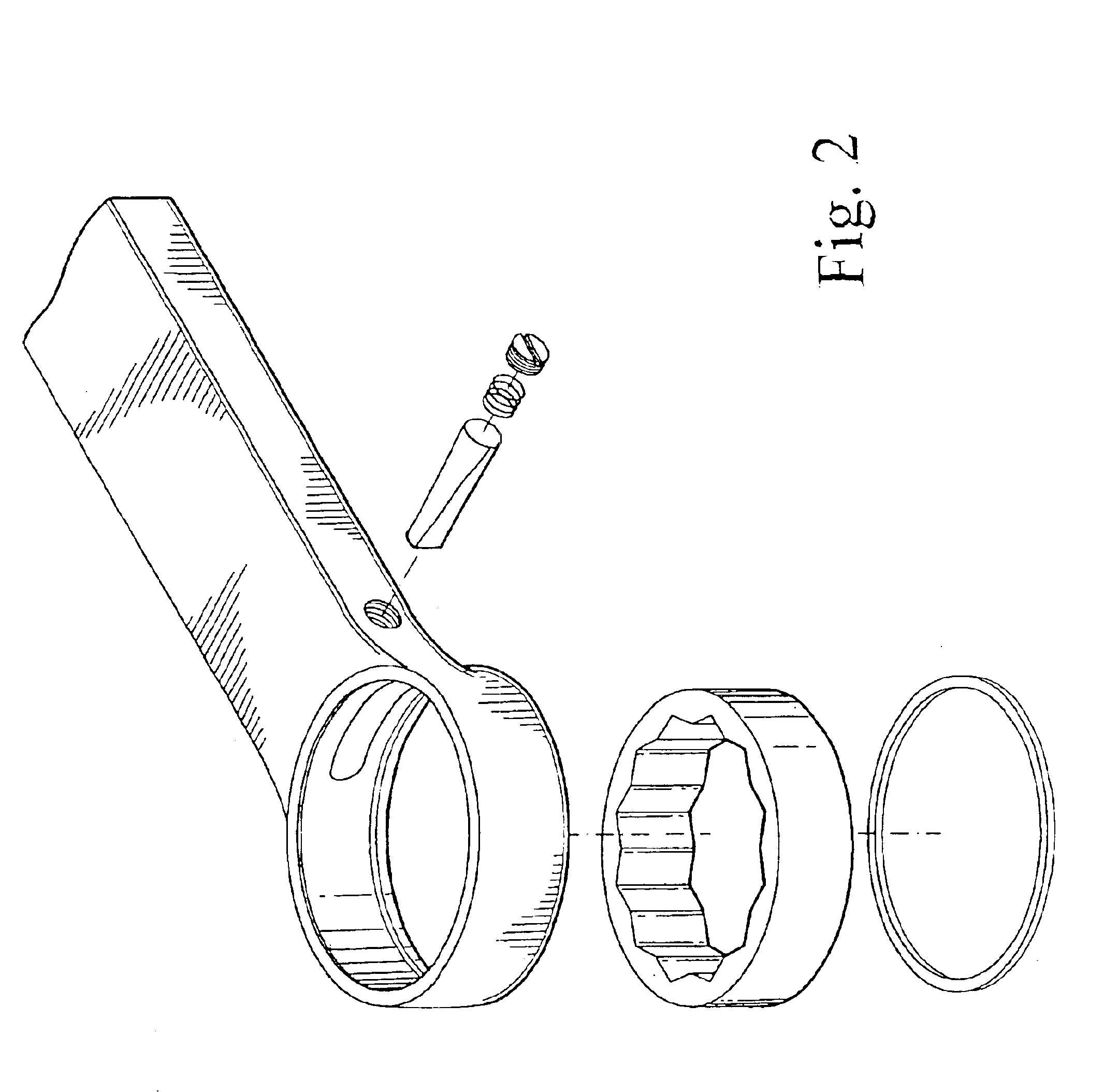

Wrench manufacturing process

A wrench manufacturing process for manufacturing a rotational-tube wrench comprises the steps of forging, annealing, rolling, punching, drawing, polishing, surface grinding, CNC rough cutting, thermal treatment, vibrating, electroplating, CNC fine cutting and assembling. The additional steps of thermal treatment and CNC or MC fine cutting not only enhance the structural toughness of the wrench but also guarantee high degree of roundness for the receptacle space thereof. The CNC or MC fine cutting also provides the inner wall of the receptacle space with fine tool marks so that the confinement strength of a rotational tube without ratchets therein can be significantly enlarged.

Owner:HSIEN CHIN CHING

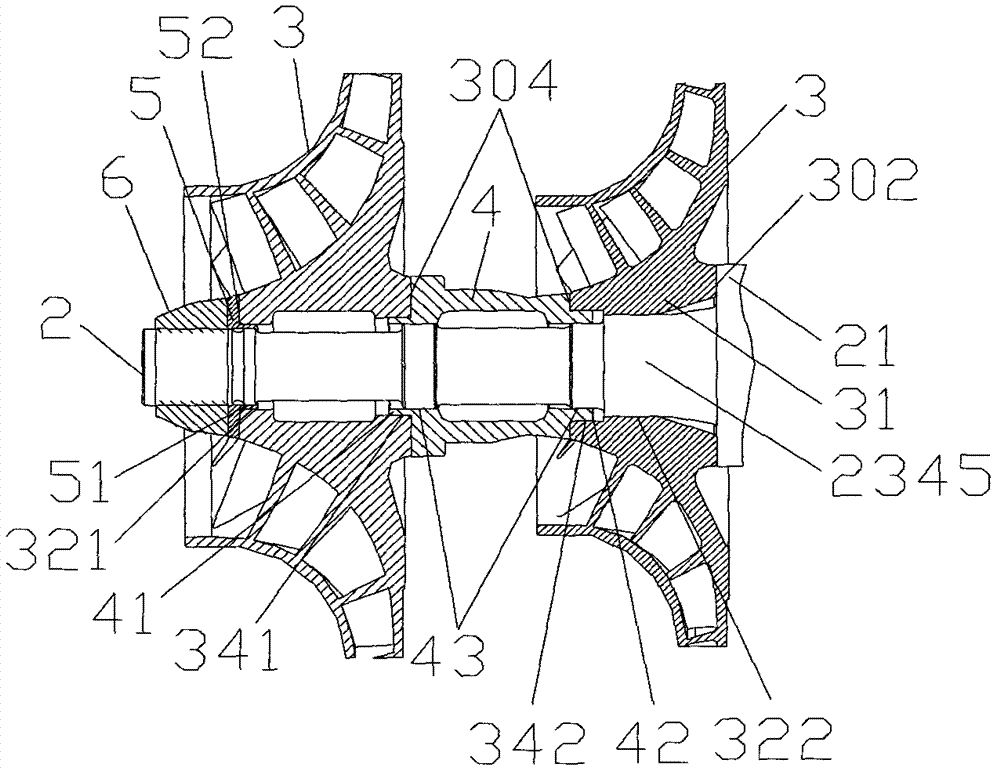

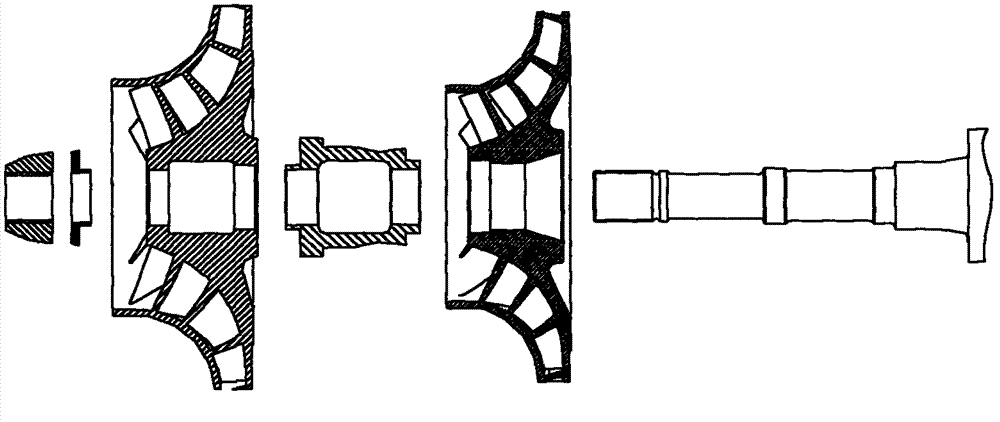

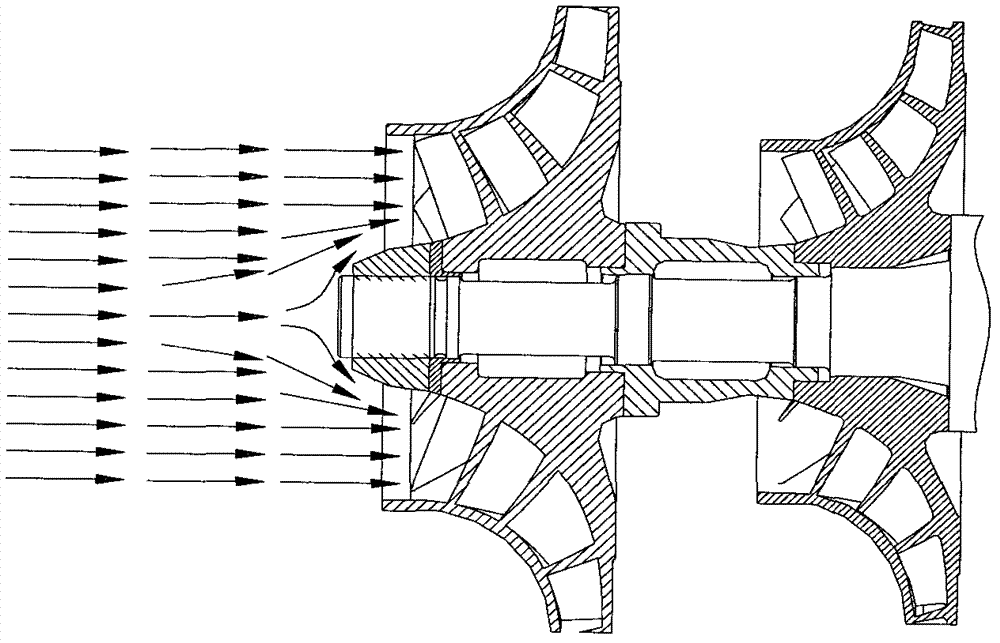

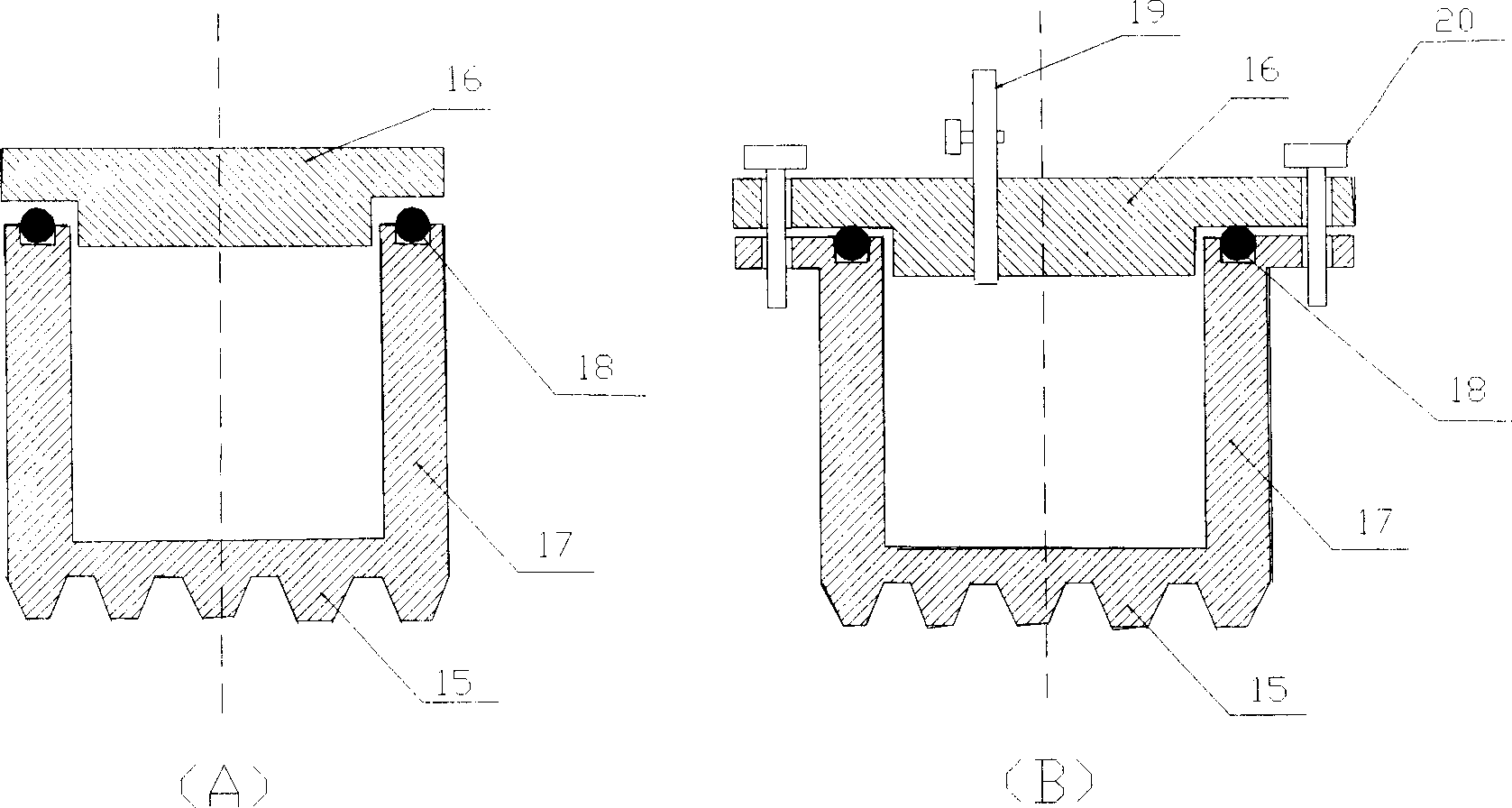

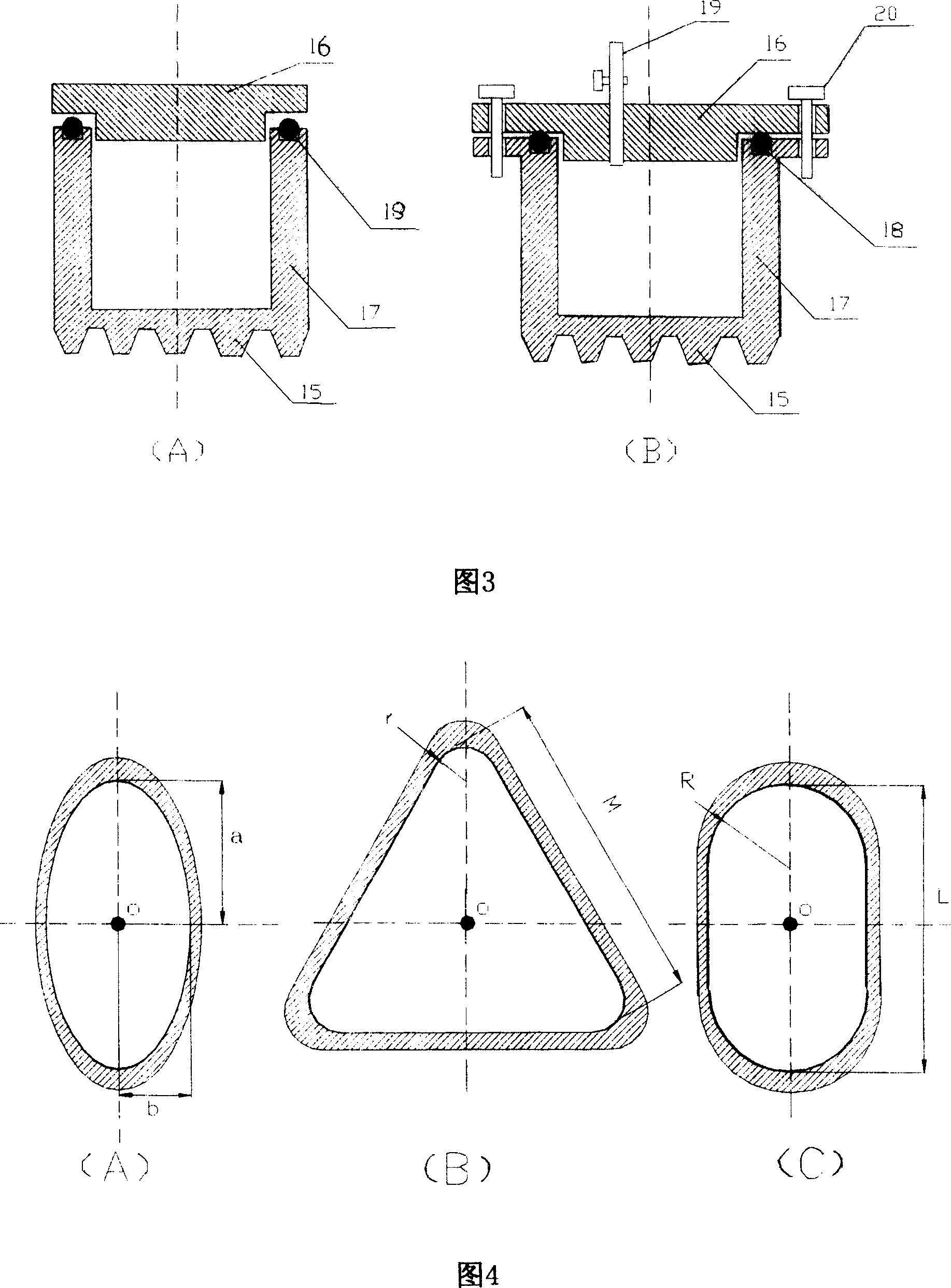

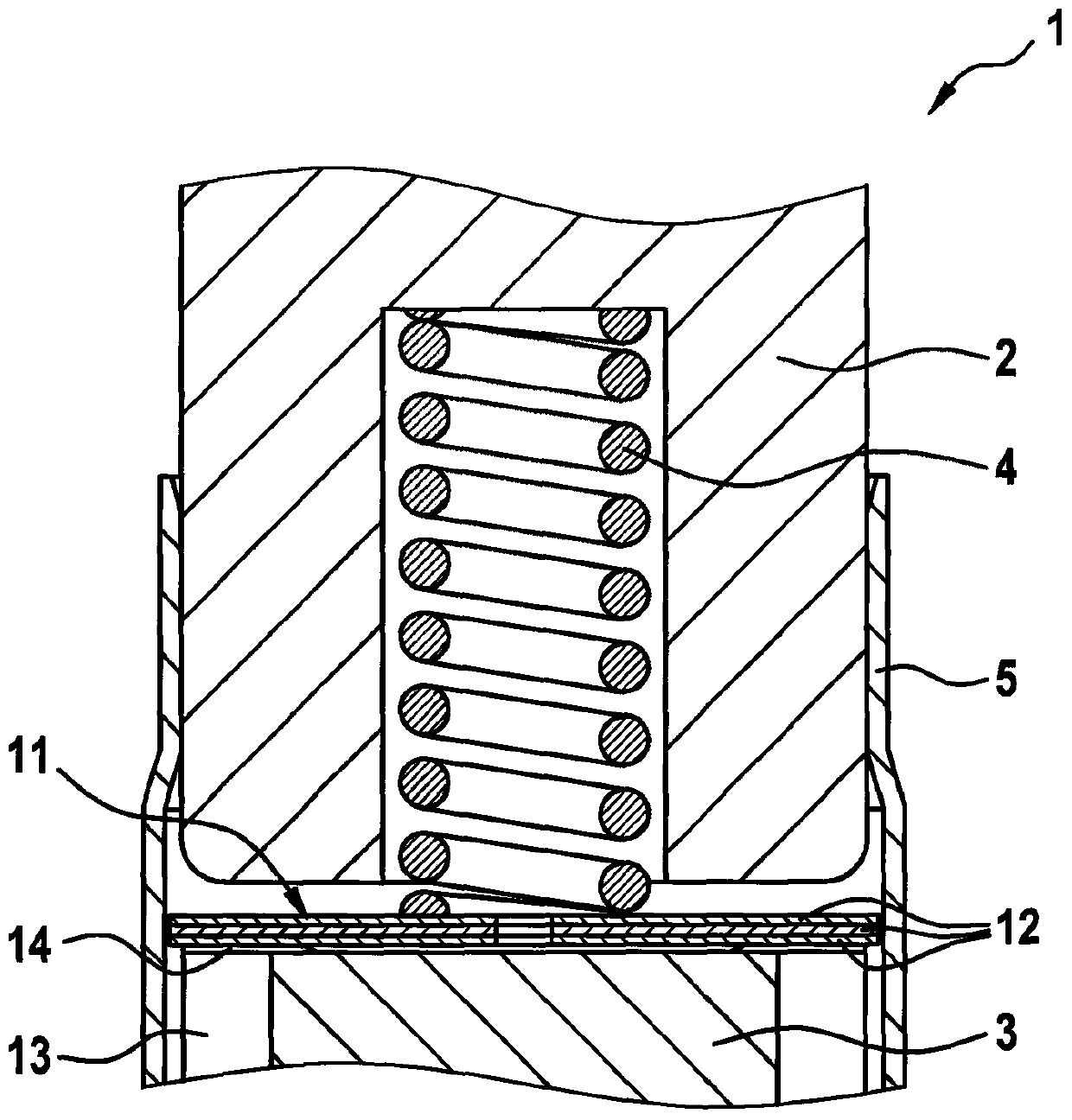

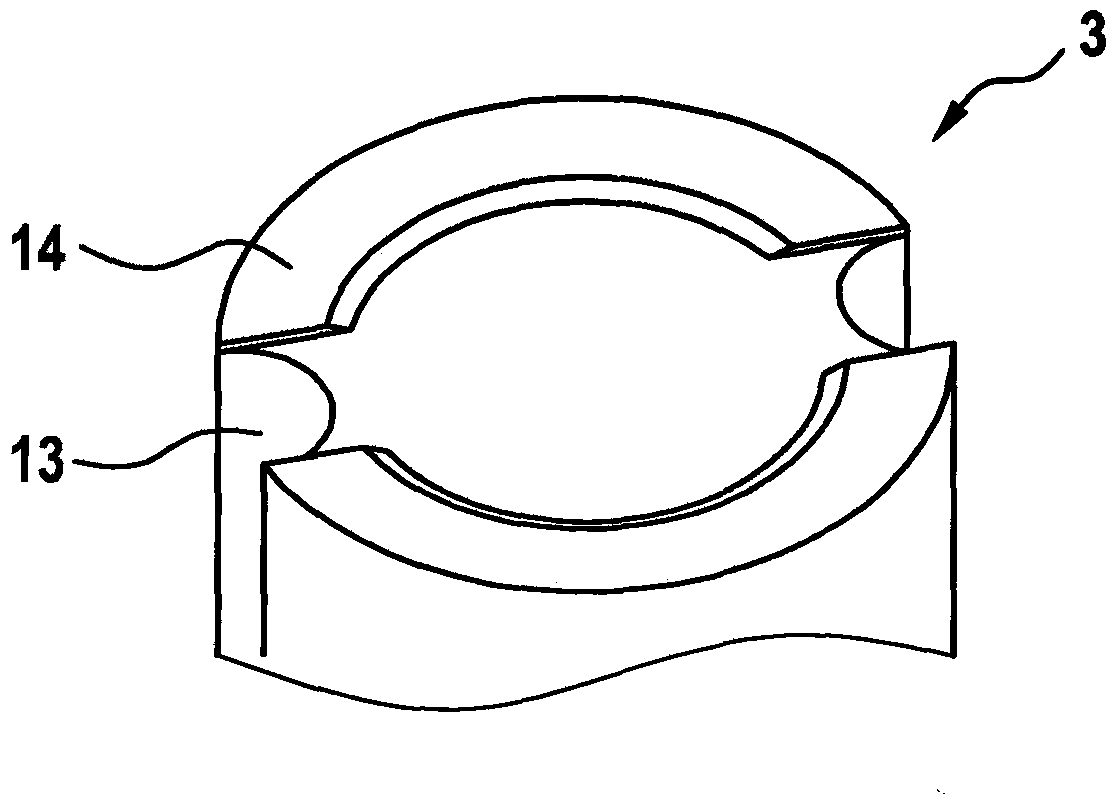

High-speed hydrodynamic machine and composition method and assembly method of rotor of high-speed hydrodynamic machine

InactiveCN103362860AReduced carrying capacityEasy to disassemblePump componentsPumpsImpellerDrive motor

The invention relates to a high-speed hydrodynamic machine of which the rotating speed is above 6000rpm, particularly between 7000rpm and 20000rpm. The high-speed hydrodynamic machine comprises a driving motor and a rotor, wherein the rotor comprises a driving motor rotating shaft and rotating impellers acting on fluid; and the rotating impeller are directly mounted on the driving motor rotating shaft, connected in a keyless manner, positioned together with the driving motor rotating shaft in an interference manner through hot-pressing in a radial direction, and compressed and pushes against a radial flange of the rotating shaft by a locking structure in an axial direction. In addition, the invention further relates to a composition method and an assembly method of the rotor of the high-speed hydrodynamic machine with the rotating speed above 6000rpm. According to the machine, since the rotating impellers are directly mounted on the driving motor rotating shaft, the transmission efficiency is improved greatly, the rotor is simpler to dismount simultaneously, and the impellers and the rotating shaft are good in coaxiality and sealability, and low in vibration.

Owner:GREE ELECTRIC APPLIANCES INC

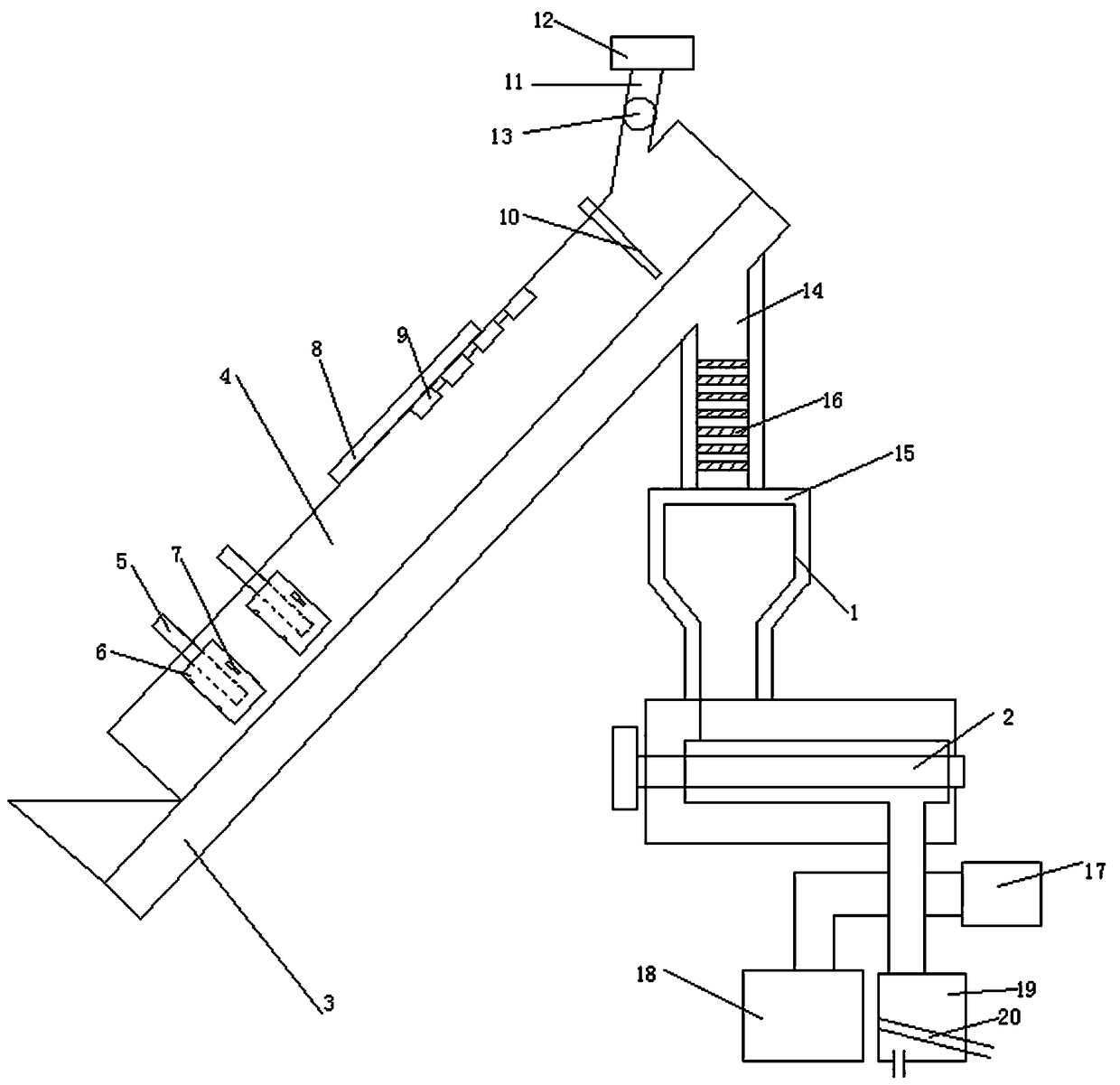

Casting sorting device

The invention discloses a casting sorting device. The casting sorting device comprises a machine frame, a conveying mechanism, a sand cleaning mechanism and a sorting mechanism. The conveying mechanism is located above one side of the sand cleaning mechanism, and the sorting mechanism is located below the other side of the sand cleaning mechanism. The conveying mechanism comprises a conveying belt. The sand cleaning mechanism comprises a frame which is connected to the machine frame in a sliding mode. The frame is obliquely arranged on the machine frame and is further connected with a plurality of connecting rods. The connecting rods are provided with a plurality of balls. The bottom side of the frame is connected with sleeves, and each sleeve is internally connected with a screw rod in a threaded mode. The screw rods are connected to the machine frame in a rotating mode. The sorting mechanism comprises a rotating disk. The rotating disk is provided with a channel opening. A plurality of sliding grooves used for communicating with the channel opening are formed in the outer side of the rotating disk. The bottom of the rotating disk is connected with a rotating rod. The rotating rod is arranged on the machine frame in a sliding mode. The rotating rod is provided with a spiral groove. A fixing rod abuts against the inside of the spiral groove. Springs are arranged between the bottom of the rotating disk and the machine frame. Compared with the prior art, sand cleaning and sorting can be conducted on castings of different weights at the same time, and working efficiency is high.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

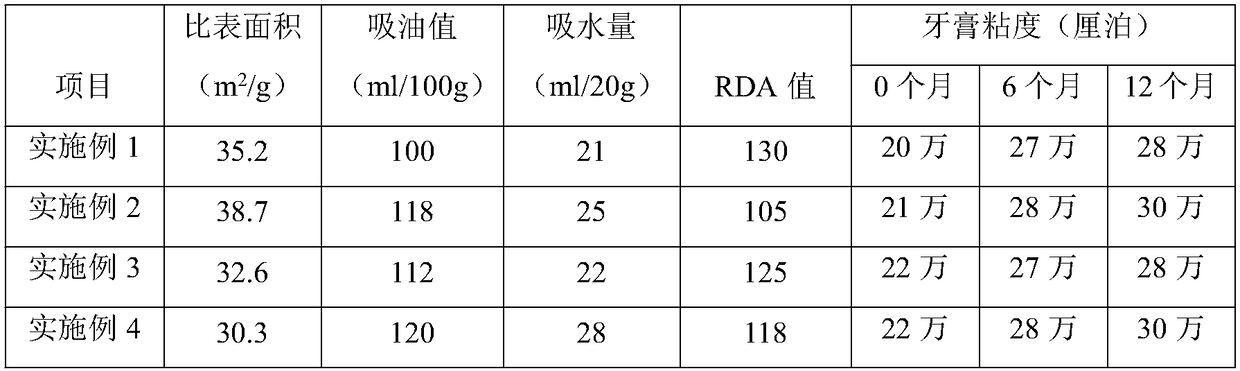

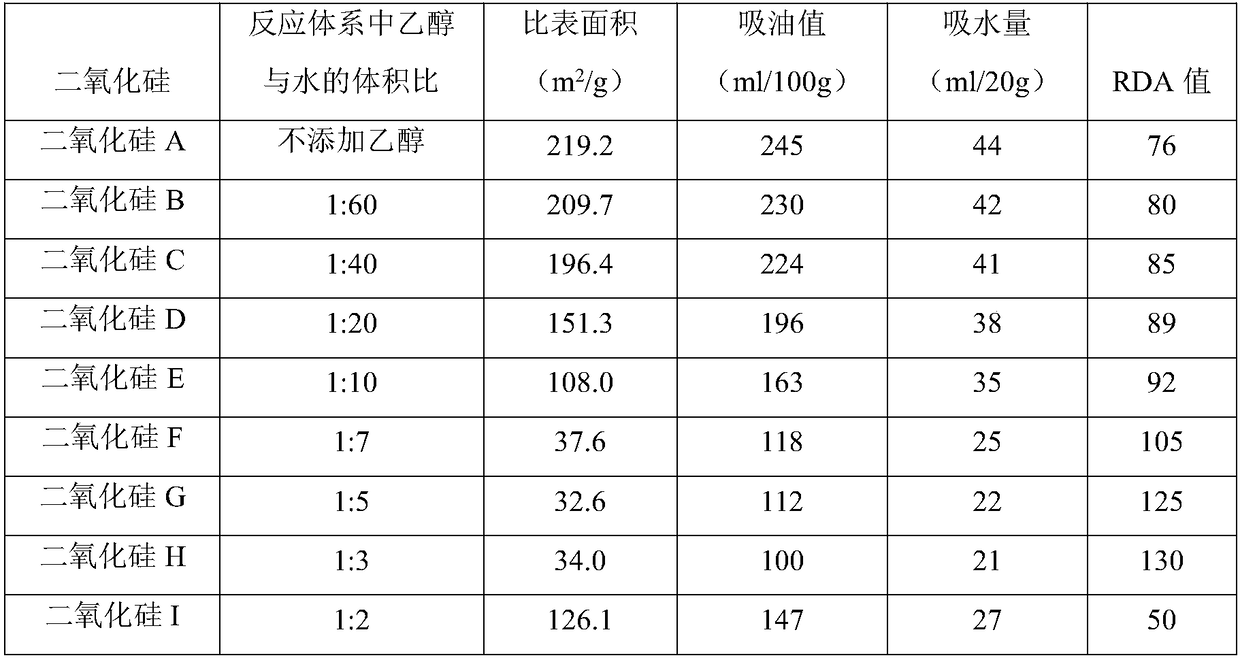

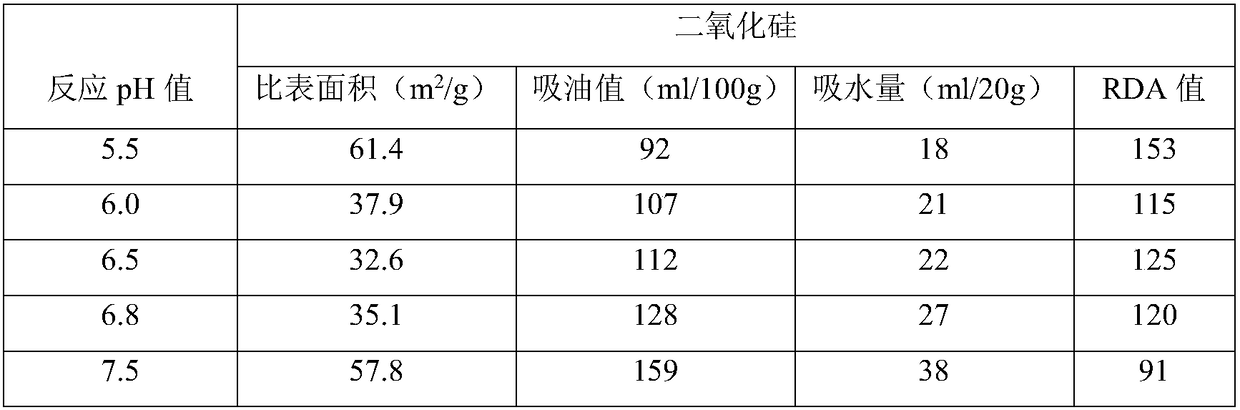

Preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide

InactiveCN108190900ASmall specific surface areaSimple methodSilicon compoundsChemistryAqueous solution

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of low-specific-surface-area high-oil-absorption-value friction type silicon dioxide.The preparation method comprises the steps that S1, 8-12 m<3> of ethanol aqueous solution is injected and heated to 60-70 DEG C, and stirring starts; S2, water glass and sulfuric acid are added dropwise to carry out a parallel flow reaction, the pH value in the reaction process is controlled to be 6.0-6.8, meanwhile, absolute ethyl alcohol is added every 5-10 minutes in the reaction process to keep the volume ratio of ethyl alcohol to water in a reaction system to be 1:(3-7), after the water glass is dropwise added, dropwise addition of sulfuric acid is stopped, and stirring continues; S3, stirring and heating are stopped, aging is conducted for one hour, and pressure filtration, washing, drying and crushing are conducted on the on formed silicon dioxide to prepare silicon dioxide. The silicon dioxide has the advantages of a low in specific surface area, a high oil absorption value, a high water absorption amount, the friction property and the like; toothpaste has good friction and cleaning performance after the silicon dioxide is used, and meanwhile, the problem of expansion of the viscosity of the toothpaste is well solved.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

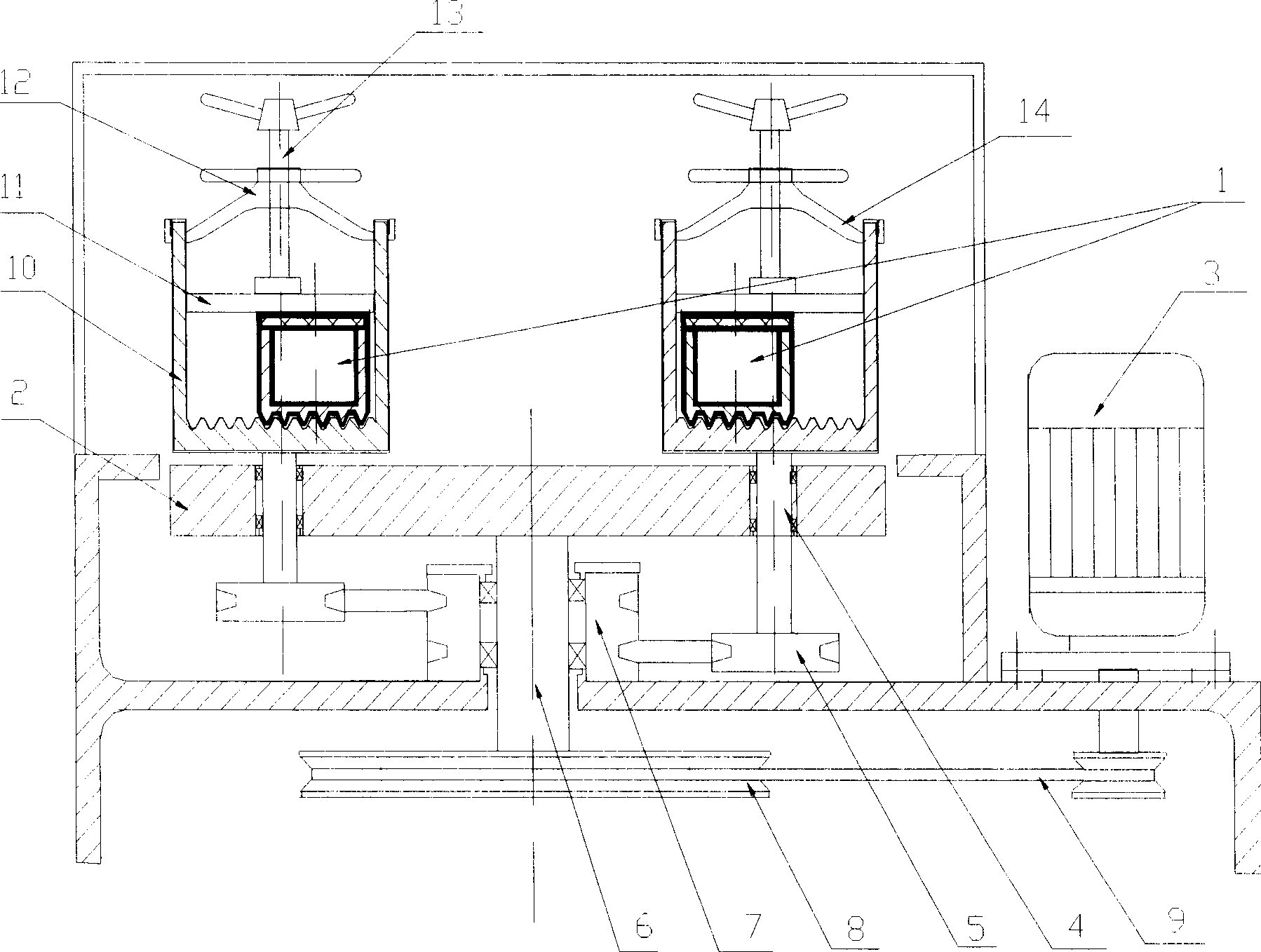

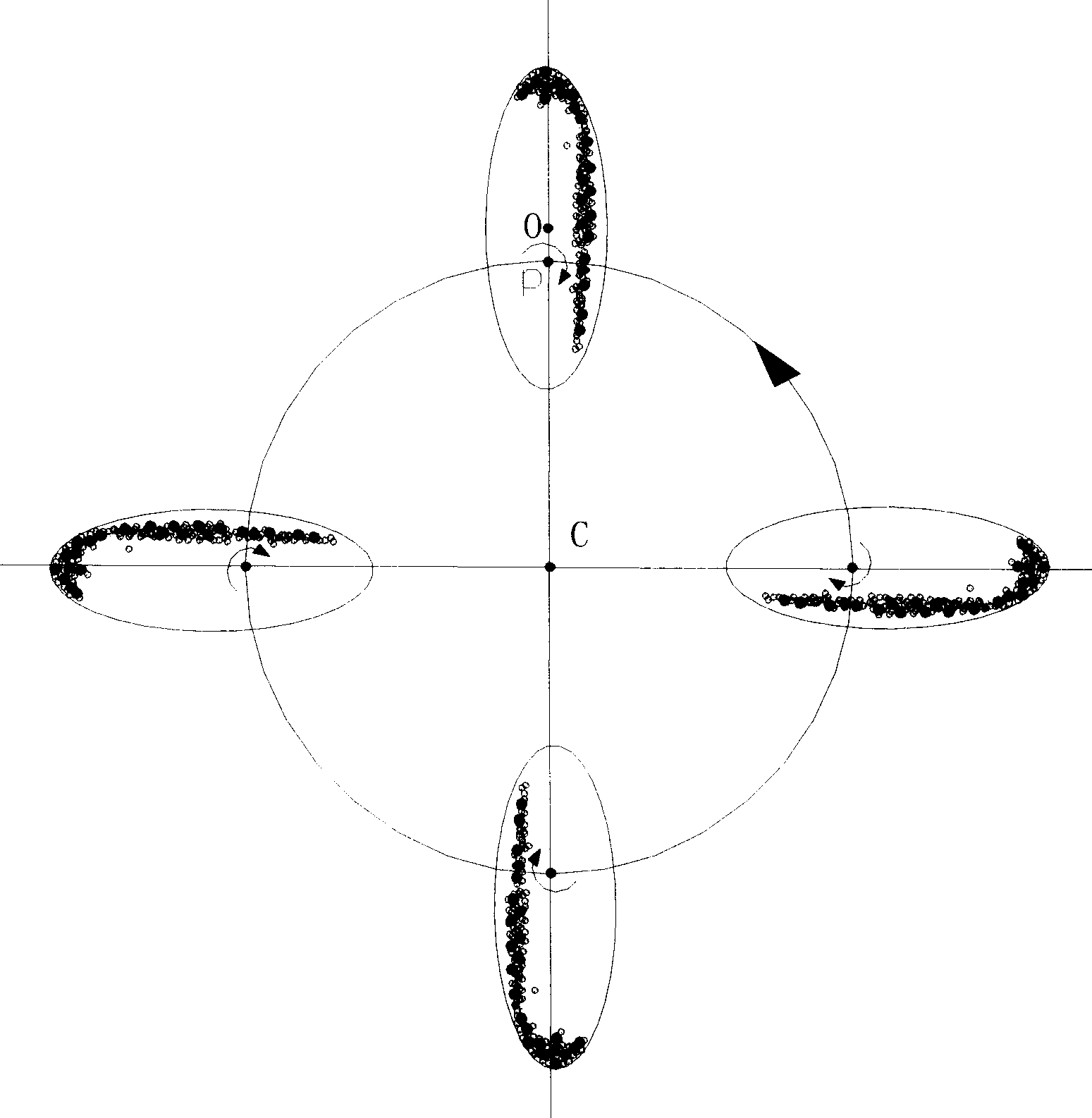

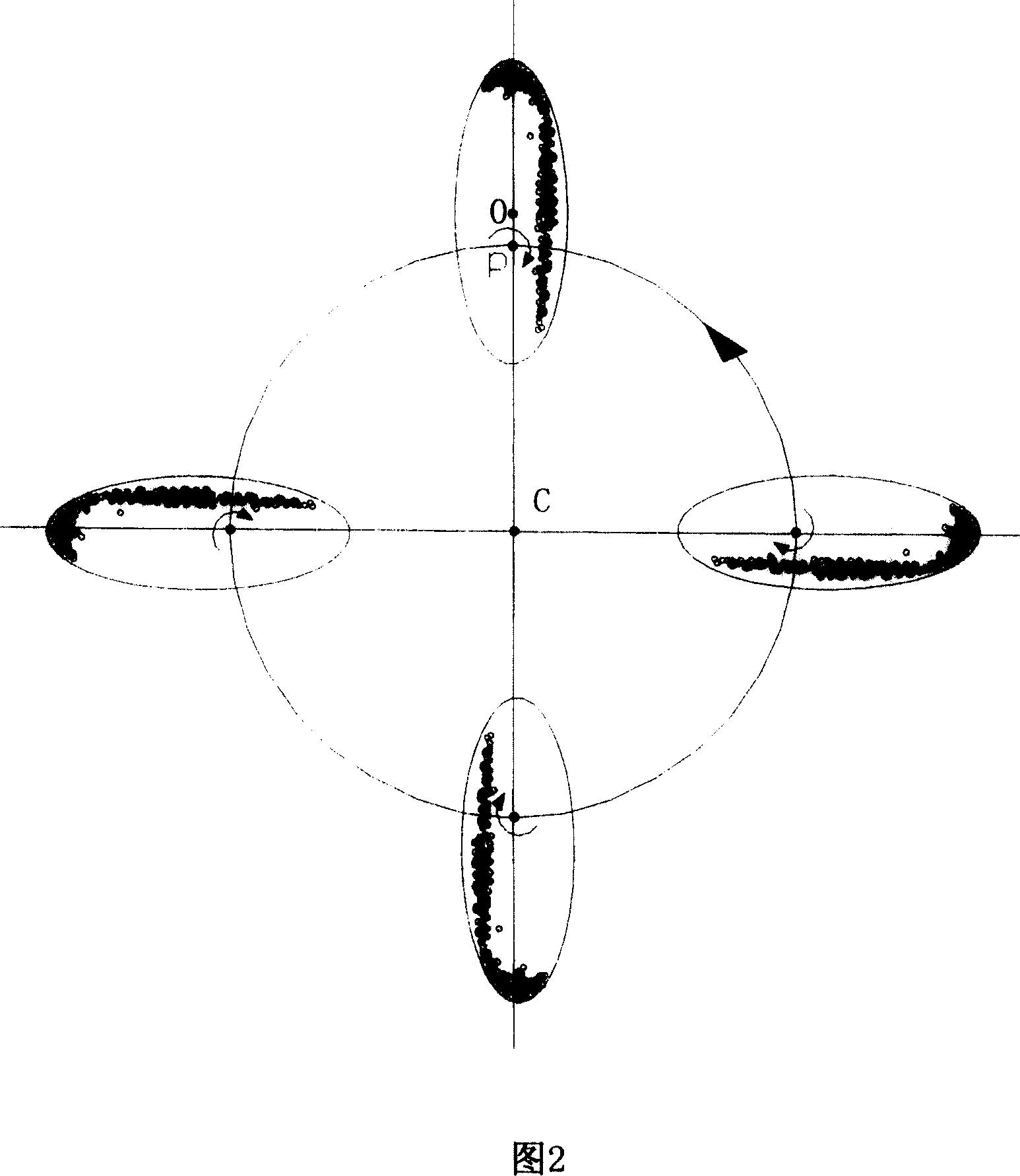

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

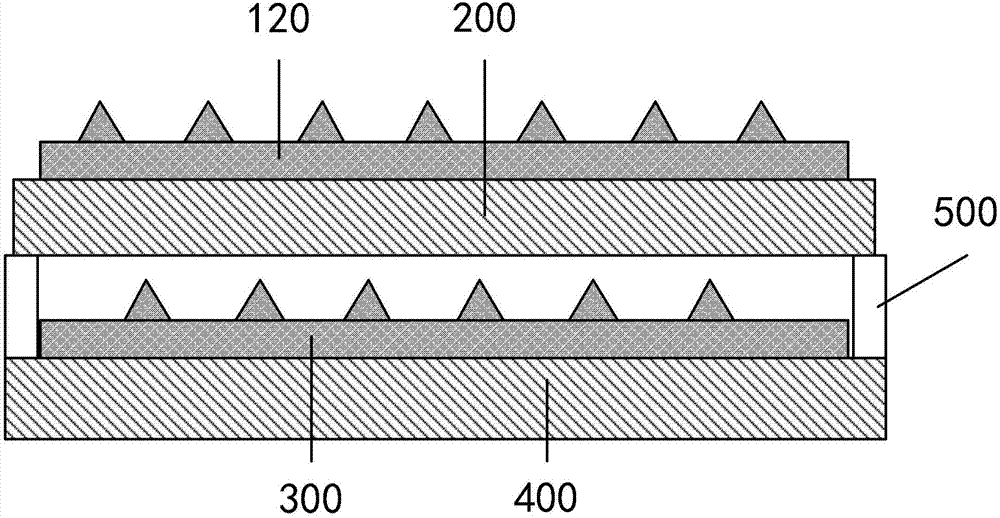

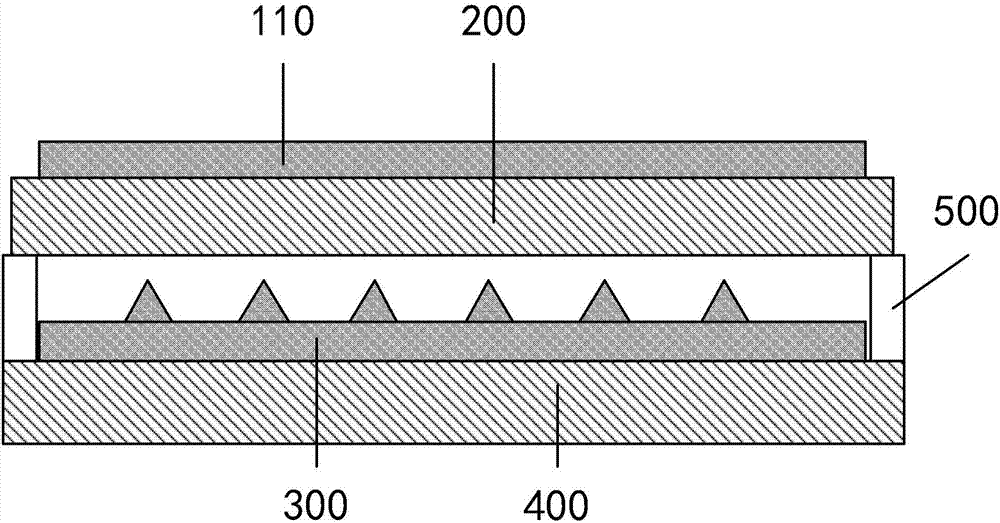

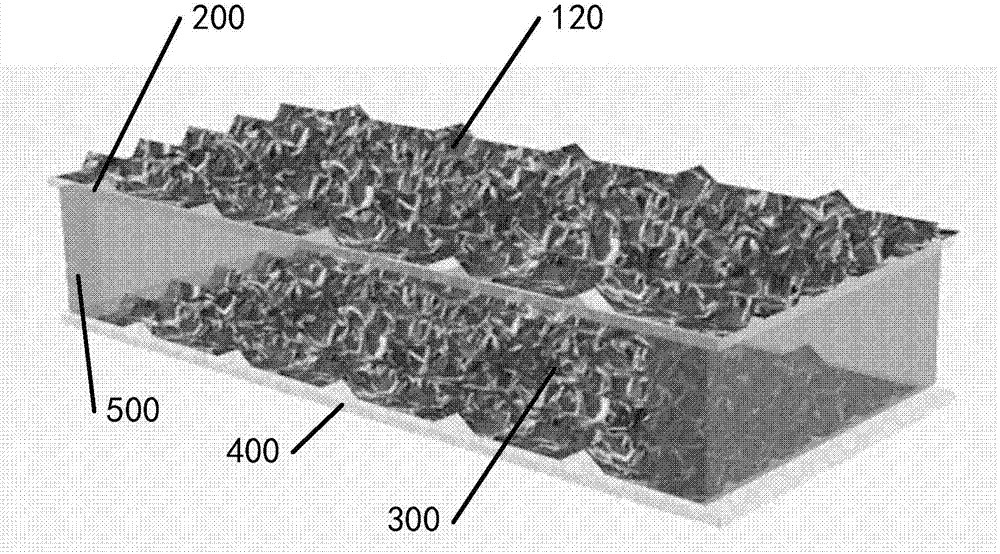

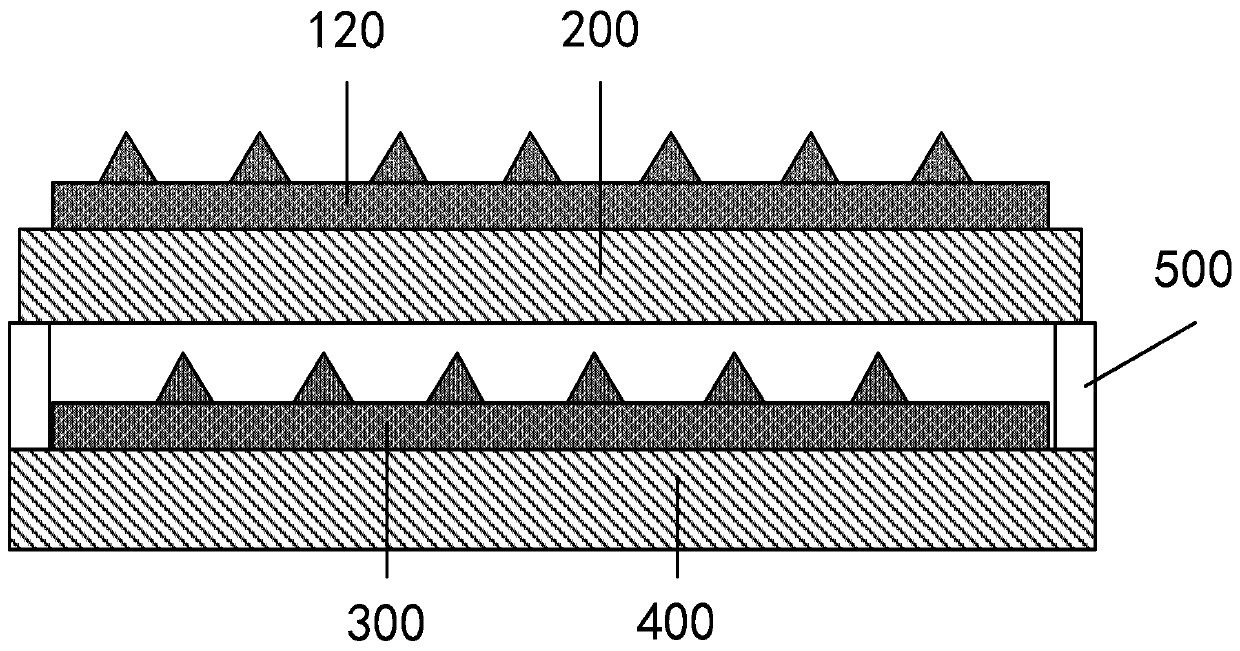

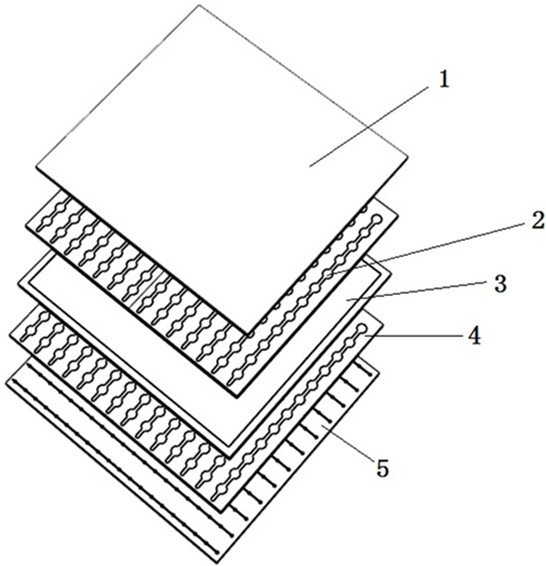

Friction generator based on folded conductive film, preparation method thereof, and integrated structure

ActiveCN106877732AIncrease the output voltageHigh output voltage and output powerFriction generatorsDuctilityFilm material

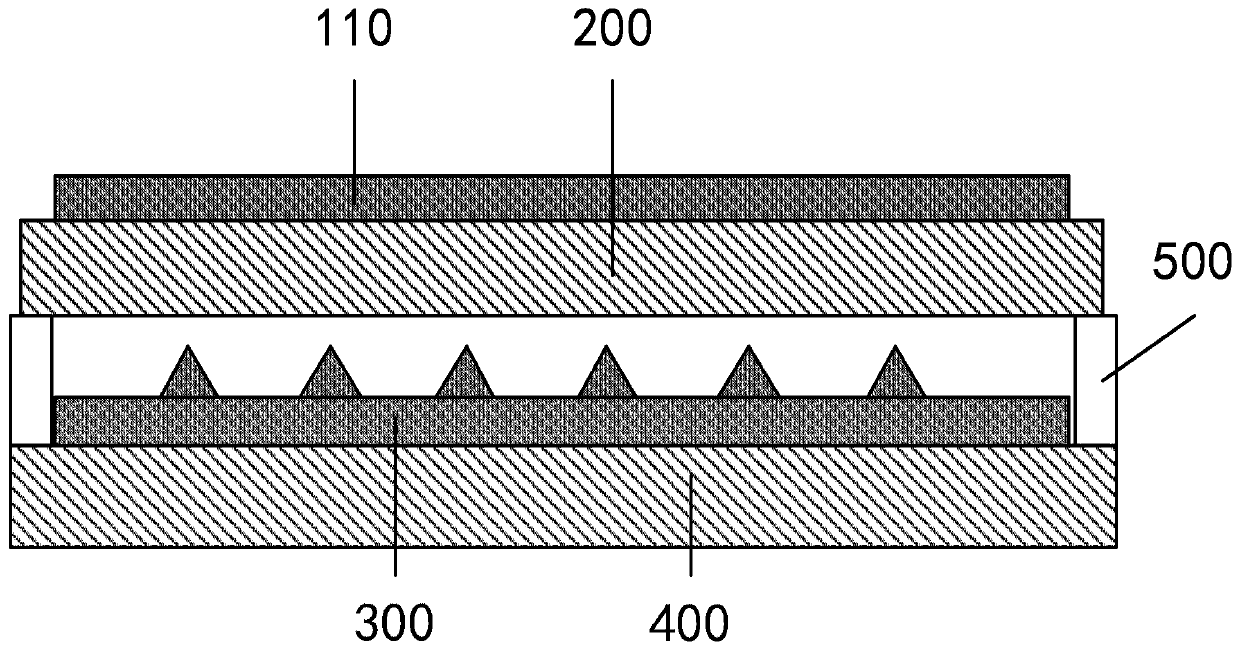

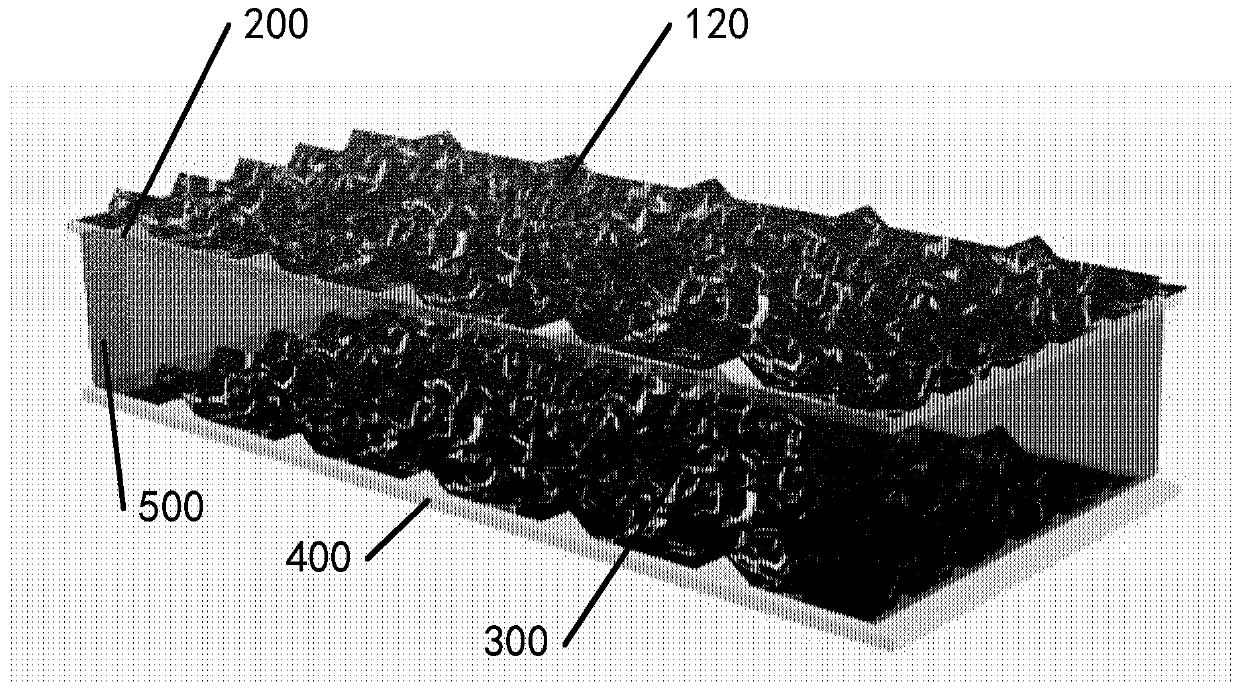

The present invention provides a friction generator based on a folded conductive film. The friction generator comprises an upper friction layer which comprises an upper insulating layer (200) made of a flexible material and an upper electrode (100) on the upper insulating layer, a lower friction layer which comprises a substrate (400) made of a flexible material and a lower electrode (300) which is on the substrate and is made of a folded conductive film material. According to the folded design, a friction area and a friction effect are improved, thus a device with a same area has larger output voltage, in a same space structure, the output voltage and output power of the friction generator are effectively improved, the integration and promotion of multiple friction generators are facilitated, the scalability of a device is also improved through folded electrodes in upper and lower positions, thus a power generation mode is broadened, power can be generated through pressure, power can be generated through drawing and bending, the versatility of the device is enhanced, and the application of the friction generator in the aspects of complex environment and the man-machine interface is facilitated.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Concave-convex bar mother chrysanthemum green tea toothpaste and preparation (method) thereof

InactiveCN101249053AQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsLow speedAdditive ingredient

The invention discloses attapulgite / wild chrysanthemum / green tea toothpaste and a production method thereof. The technical proposal is that: the production method comprises the following steps: steaming for enzyme deactivation, preparing ingredients, low-speed stirring, pulverization and pulping, milling, high-speed stirring, vacuum degassing and packaging. Through the steps, finished products of attapulgite / wild chrysanthemum / green tea toothpaste are obtained. The attapulgite / wild chrysanthemum / green tea toothpaste contains pasty attapulgite clay, fresh green tea, fresh honeysuckle flower, fresh peppermint, fresh lalang grass rhizome, sodium dodecylsulfate, potassium sorbate and deionized water. Plant fibers produced by pulverization and milling can not only increase the viscosity of the toothpaste but also improve the abrasion effect and stability of the toothpaste. The attapulgite / wild chrysanthemum / green tea toothpaste has soft and fine texture and oral cleaning and refreshing functions, and can adsorb and eliminate odors in oral cavity. The inventive method is suitable for the production of attapulgite / wild chrysanthemum / green tea toothpaste, herbal toothpaste and other medicinal toothpaste.

Owner:许盛英

Attapulgite mother chrysanthemum green tea toothpaste and preparation method thereof

InactiveCN100584309CQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsAdditive ingredientToothpaste

The invention discloses attapulgite / wild chrysanthemum / green tea toothpaste and a production method thereof. The technical proposal is that: the production method comprises the following steps: steaming for enzyme deactivation, preparing ingredients, low-speed stirring, pulverization and pulping, milling, high-speed stirring, vacuum degassing and packaging. Through the steps, finished products of attapulgite / wild chrysanthemum / green tea toothpaste are obtained. The attapulgite / wild chrysanthemum / green tea toothpaste contains pasty attapulgite clay, fresh green tea, fresh honeysuckle flower, fresh peppermint, fresh lalang grass rhizome, sodium dodecylsulfate, potassium sorbate and deionized water. Plant fibers produced by pulverization and milling can not only increase the viscosity of the toothpaste but also improve the abrasion effect and stability of the toothpaste. The attapulgite / wild chrysanthemum / green tea toothpaste has soft and fine texture and oral cleaning and refreshing functions, and can adsorb and eliminate odors in oral cavity. The inventive method is suitable for the production of attapulgite / wild chrysanthemum / green tea toothpaste, herbal toothpaste and other medicinal toothpaste.

Owner:许盛英

Hydrophobic high-wear-resistance paper pulp material preparation method and product thereof

InactiveCN109577074AEnhance friction performanceEasy to prepareCoatings with pigmentsWater-repelling agents additionSurface modificationFluorocarbon

The invention relates to a hydrophobic high-wear-resistance paper pulp material and a preparation method thereof. According to the method, a fluorocarbon compound is used as a hydrophobic agent and added into a paper pulp forming formula to achieve a high hydrophobic effect; by an atomic layer deposition technique, surface modification of a paper pulp material with an inorganic nano oxide is realized, surface roughness of the paper pulp material is improved, and surface wear resistance of the paper pulp material is realized. Compared with the prior art, the hydrophobic wear-resistant paper pulp material has advantages that abrasion performance of paper pulp is substantially enhanced, and an excellent water-resistant effect is achieved. In addition, the preparation method is simple, and performances of an obtained product are evidently superior to those of existing products on the market.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

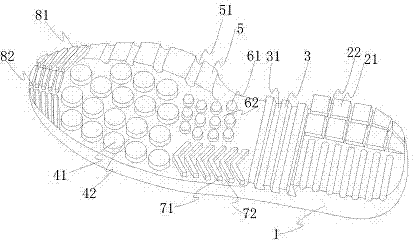

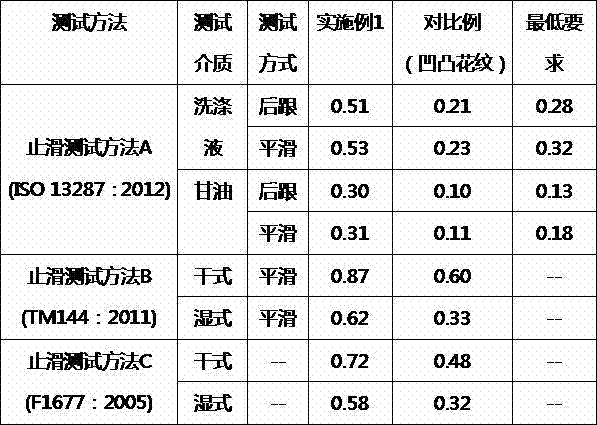

Anti-slide shoe sole and shoe with shoe sole

The invention relates to a sole and provides an anti-slide shoe sole and a shoe with the shoe sole. The anti-slide shoe sole has the anti-slide performance in both processes of standing contact and force-applied walking, and people also can stably walk even if a slippery ground. The anti-slide sole comprises an outsole, wherein the outsole corresponding to a heel, an arch, metatarsal bones, and a toe of the sole is respectively composed of a heel zone, an arch zone, a metatarsal bones zone and a toe zone; a square bulge zone is arranged on the heel zone of the outsole, and the square bulge zone is formed by several square bulges, a draining grove for draining fluid is arranged between adjacent square bulges; a cylindrical bulge zone is arranged on the metatarsal bones zone, and composed of several cylindrical bulges; a draining gap for draining fluid forms between adjacent cylindrical bulges; a strip-shaped bulge zone is arranged on the toe zone of the outsole and formed by a plurality of strip-shaped bulges, and a draining groove for draining fluid is formed between adjacent strip-shaped bulges.

Owner:MAOTAI FUJIAN SOLES CO LTD

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

Concave-convex stick honeysuckle flower green tea toothpaste and preparing method

InactiveCN101244024AImproved adsorption and moisturizing propertiesQuality improvementCosmetic preparationsToilet preparationsBorneolChemistry

The invention discloses an attapulgite honeysuckle green tea toothpaste and a production method of the toothpaste. The production method comprises the following steps: steaming, mixture making, agitating at a low speed, cutting and mealing, grinding, agitating at a high speed, vacuum degassing and canning to from attapulgite honeysuckle green tea toothpaste finished products. The attapulgite honeysuckle green tea toothpaste comprises paste attapulgite clay, fresh tea, fresh honeysuckle, sodium dodecyl sulfate, potassium sorbate, borneol and deionized water. The attapulgite honeysuckle green tea toothpaste has the advantages of softness, finess, lustration, uniformity and the toothpaste can adsorb and eliminate various offensive odors; meanwhile, the plant fiber after cutting and grinding can increase the consistency of the paste body of the toothpaste and the friction effect and the stability of the toothpaste. The toothpaste production method is suitable for producing attapulgite honeysuckle green tea toothpaste, Chinese herbal medicine toothpaste and other medicine toothpaste.

Owner:贾剑

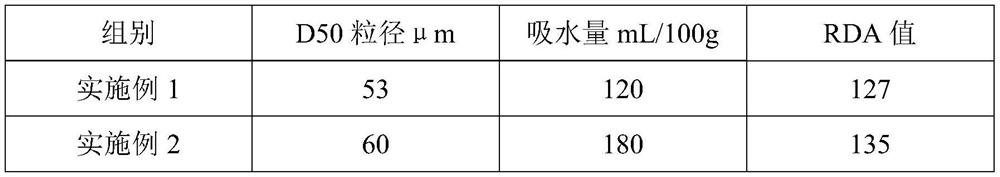

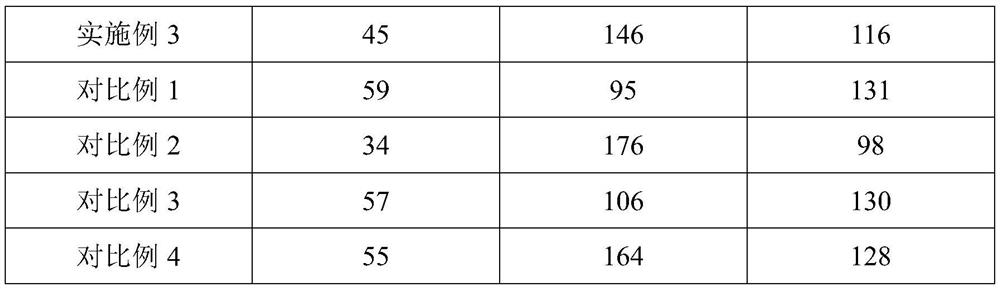

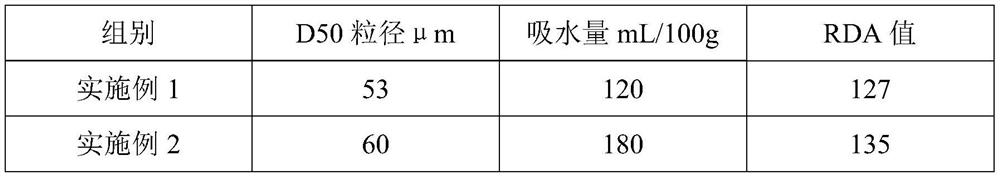

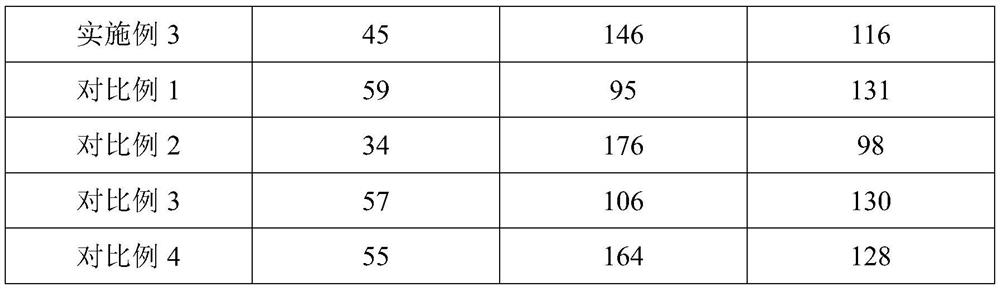

High-loading-capacity and high-cleanliness friction type silicon dioxide for tooth powder and preparation method of silicon dioxide

ActiveCN113350205AIncrease friction effectEasy to cleanCosmetic preparationsSilicaPhysical chemistryDodecyl sulfate

The invention belongs to the technical field of silicon dioxide, and particularly relates to high-loading-capacity and high-cleanliness friction type silicon dioxide for tooth powder and a preparation method of the silicon dioxide. Sodium silicate with a certain concentration and a modulus of 1.5-3.5 reacts with sulfuric acid with a certain concentration under the action of sodium dodecyl sulfate to prepare the high-loading-capacity and high-cleanliness friction type silicon dioxide for the tooth powder. The high-loading-capacity and high-cleaning friction type silicon dioxide for the tooth powder is high-grinding-type and high-adsorption precipitated silicon dioxide, is large in particle size, is not easy to disperse, has the water absorption capacity of 120-180mL / 100g, can prevent moisture when being applied to the tooth powder, and prevents the tooth powder from absorbing moisture and caking in the tooth powder storage process. In addition, the high-loading-capacity and high-cleaning-capacity friction type silicon dioxide for the tooth powder has high loading capacity, and the performance of the tooth powder can be improved.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

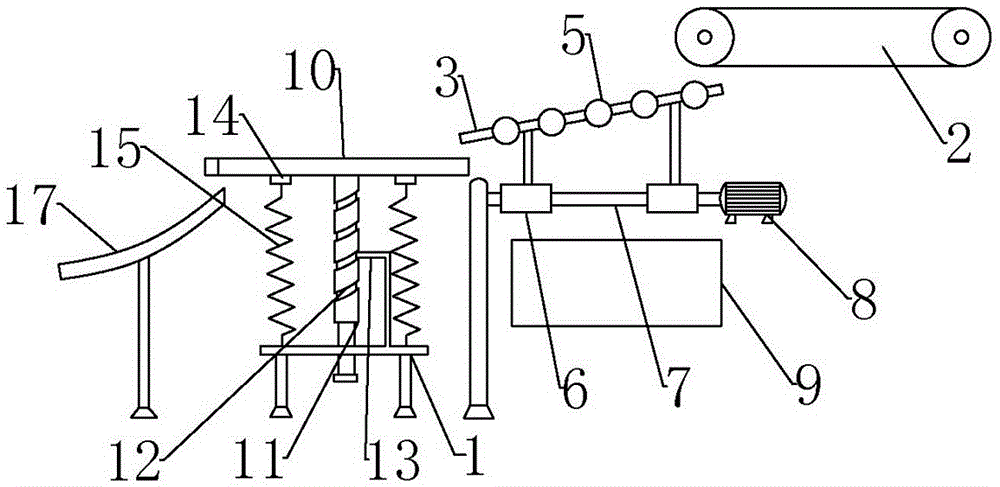

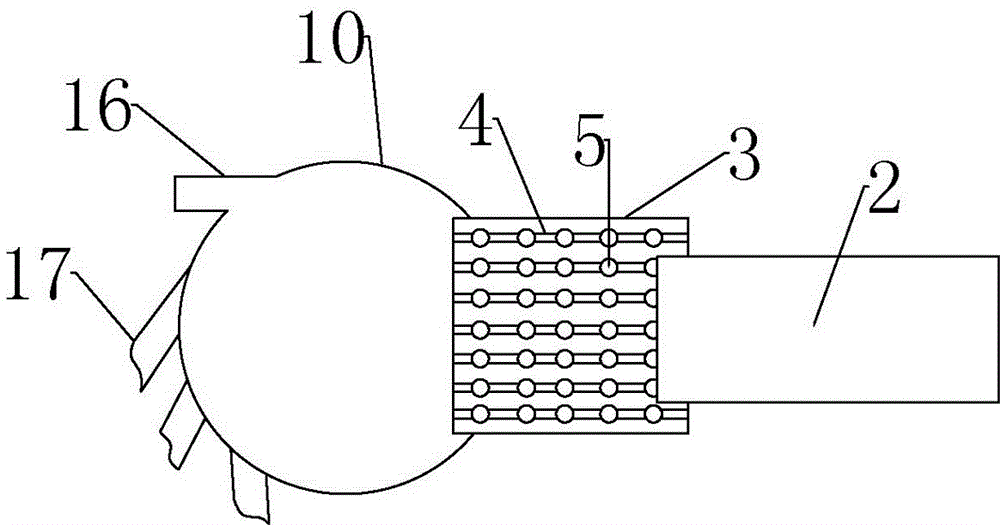

Rice husking machine convenient to separate rice from bran

InactiveCN108722531AIncrease friction effectIncrease temperatureGrain millingBroken riceElectric heating

The invention relates to a rice husking machine convenient to separate rice from bran. The rice husking machine comprises a hopper, wherein a lifting conveyor belt is arranged on one side of the hopper; a whitening chamber is arranged under the hopper; a cover body is arranged above the lifting conveyor belt; a solar heat collecting plate is arranged on the upper surface of the cover body; an electric heating panel is further arranged in the cover body in a series connection way; a discharge pipeline is arranged at the lower end of the lifting conveyor belt; a discharge pipe is arranged at thelower end of the whitening chamber; a fan is arranged on one side of the discharge pipe; a bran storage bag for collecting rice husk is arranged at a position, on the corresponding surface of the fan, of the other side of the discharge pipe; a filter tank is further arranged under the discharge pipe; and a sieve is arranged in the filter tank. According to the rice husking machine convenient to separate the rice from the bran provided by the invention, the outer surface of unpolished rice is dried, so that a rubbing effect is improved; and after materials are whitened through the whitening chamber, bran and broken rice are collected by the bran storage bag through the fan, the winnowed rice is filtered through the filter tank, the rice meeting the specifications is filtered, and the broken rice is filtered through the sieve.

Owner:常州市武进双湖粮油机械股份有限公司

Corncob Chinese herbal medicine tooth powder

InactiveCN108309863ASmall friction hardnessNo grittinessCosmetic preparationsHydroxy compound active ingredientsLiquoricesTooth brushing

The invention relates to corncob Chinese herbal medicine tooth powder. The corncob Chinese herbal medicine tooth powder is prepared from the following raw materials: active corncob powder, herba agrimoniae, radix melastomae, folium callicarpae formosanae, Chinese iris seed, liquorice root, borneol, aminomethylbenzoic acid, sodium dodecyl sulfate and water. The active corncob powder obtained by activating corncob powder and other raw materials are added into a ball grinding mill and are subjected to wet-method grinding; then a mixture is dried and ground to obtain the corncob Chinese herbal medicine tooth powder. The corncob Chinese herbal medicine tooth powder provided by the invention has the advantages of good stability, no caking, cool and fresh mouthfeel, softness, fineness and smoothness; the abrasion of enamel on surfaces of teeth can be effectively reduced in a tooth brushing process; the corncob Chinese herbal medicine tooth powder is suitable for removing halitosis and preventing oral diseases.

Owner:SHAANXI SCI TECH UNIV

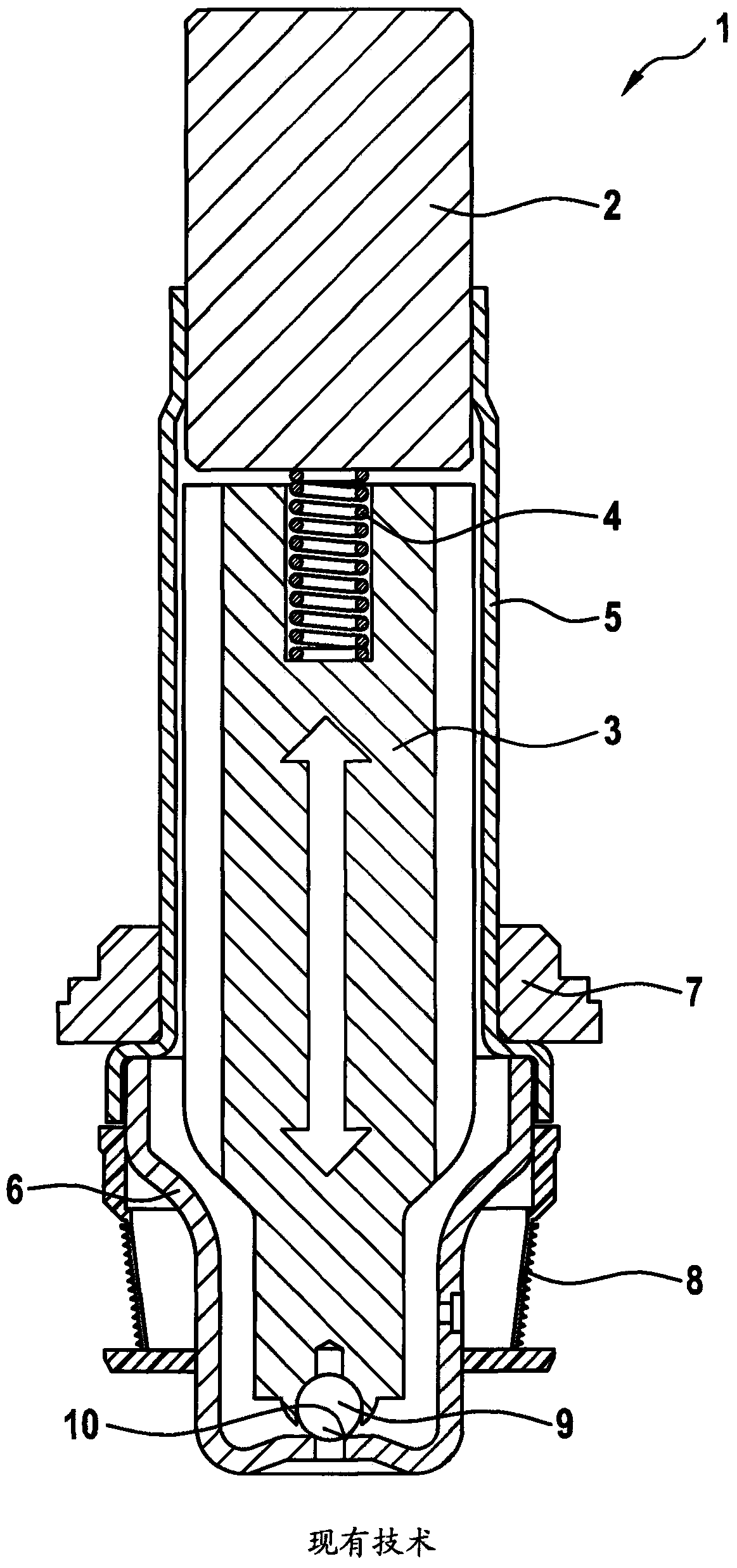

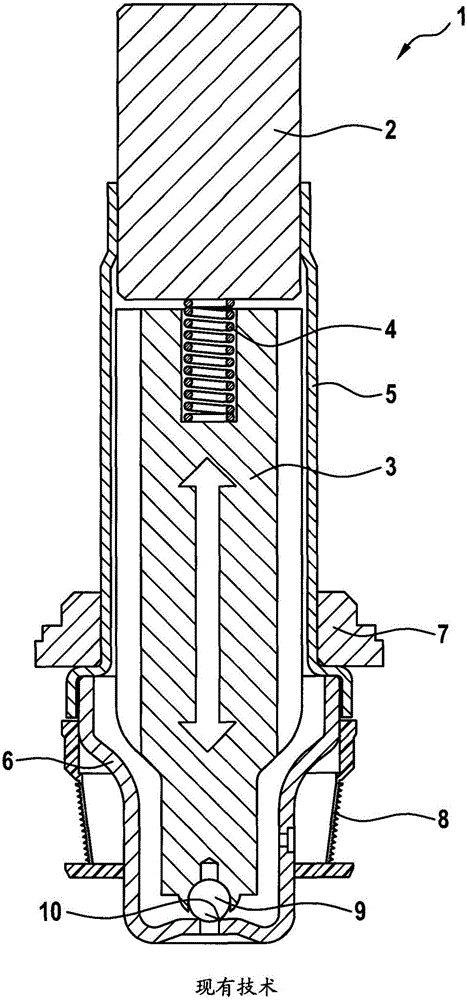

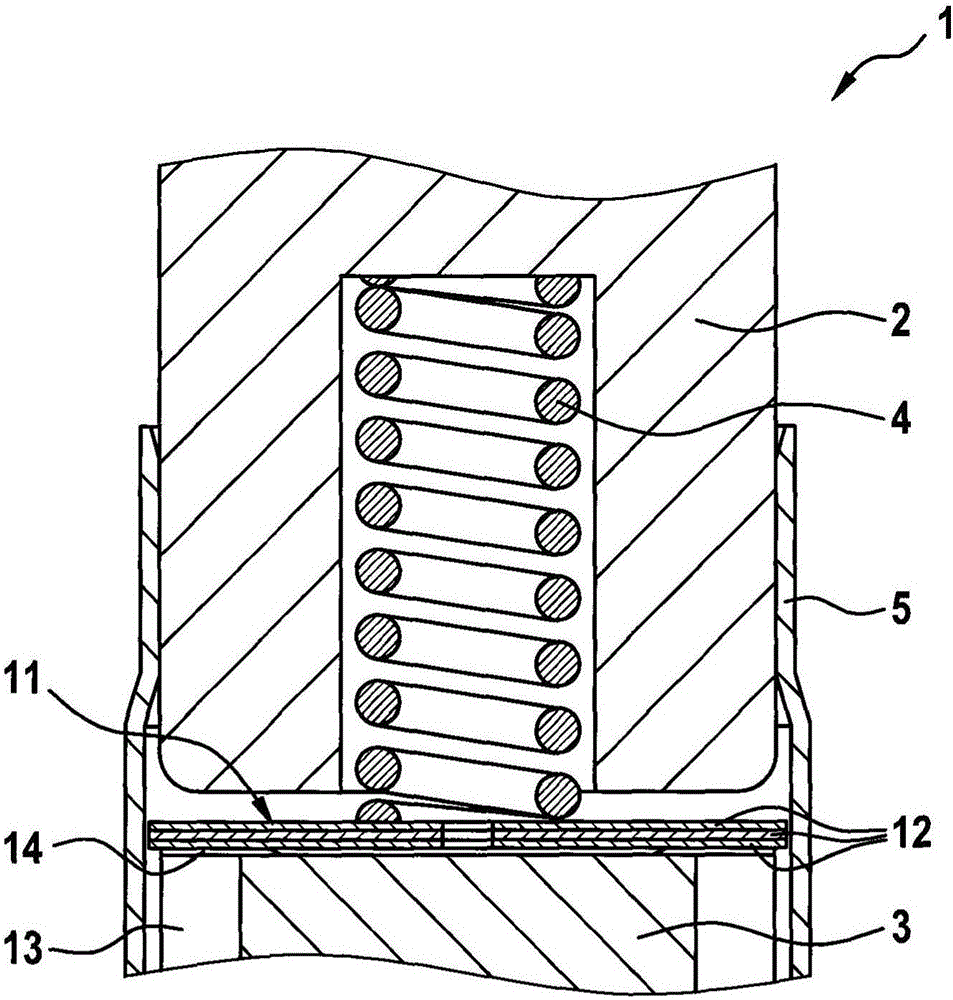

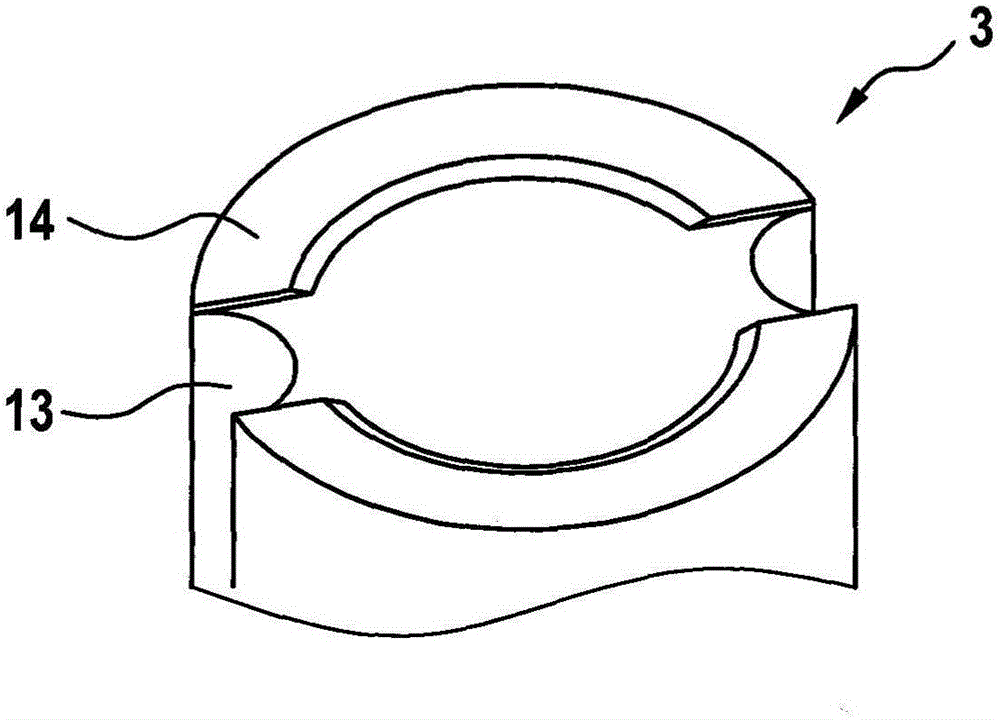

Solenoid valve closed when de-energized

ActiveCN106369205BCurved bigBuffer armature shiftOperating means/releasing devices for valvesMagnetsSolenoid valveVALVE PORT

PROBLEM TO BE SOLVED: To prevent a valve opening click sound occurring in a case where an armature collides with a polar core in electrification.SOLUTION: In a valve closing type solenoid valve 1 with no current, a polar core 2 is fixed and arranged, an armature 3 includes a valve sleeve 5 arranged so as to be displaceable in an axial direction, and in order to eliminate a valve closing element cooperating with the armature 3 into a valve seat, a compression spring 4 acts between the polar core 2 and the armature 3. The valve 1 is characterized in that between the polar core 2 and the armature 3, is formed means 11 of hydraulically buffering displacement of the armature 3.SELECTED DRAWING: Figure 2

Owner:ROBERT BOSCH GMBH

Semi-metal friction piece machining method

InactiveCN108582810AImprove the friction effectImprove toughness and hardnessPhosphoric acidPressure casting

The invention discloses a semi-metal friction piece machining method. According to the semi-metal friction piece machining method, by means of the manner that titanium phosphate and inorganic whiskersare added in the preparation process of friction pieces, the friction effect and tenacity of the friction pieces are improved, preheating by hot steam sintering is performed again after the frictionpieces are molded by squeezing in machining on the friction pieces, pressure casting molding is performed on the preheated friction pieces after preheating, the tenacity and hardness of the friction pieces in preparation and machining are improved, so that the wearproof effect of the friction pieces in use is improved, and the anti-wear performance of the friction pieces is improved.

Owner:来安县隆华摩擦材料有限公司

High-friction textile raw material and preparation method thereof

PendingCN113845722AIncrease friction effectEasy to prepareChemical vapor deposition coatingSurface modificationWoven fabric

The invention provides a high-friction textile raw material and a preparation method thereof, wherein a high polymer material is doped with an inorganic nano material, so that the friction force of plastic is increased. The method comprises the following steps: (1) grinding a nano material and a high polymer material together by using a vibration mill; and (2) modifying an inorganic nano oxide on the surface of the high polymer material by using an atomic layer deposition technology, so that the surface of the high polymer material is rougher. The preparation method is simple, and the performance of the obtained product is obviously higher than that of existing market products.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

High-cleaning-power and high-viscosity friction type silicon dioxide and preparation method thereof

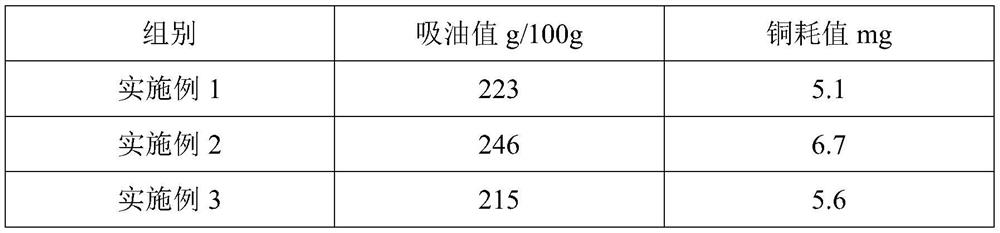

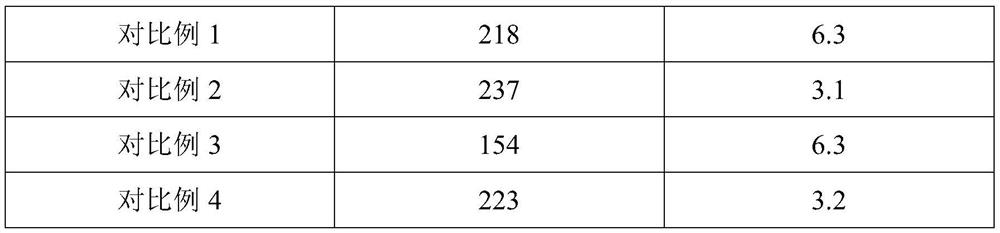

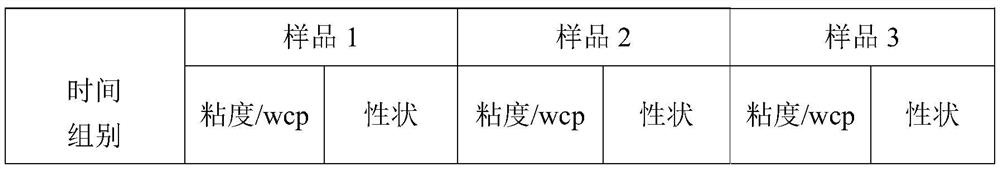

The invention belongs to the technical field of silicon dioxide, and particularly relates to high-cleaning-power and high-viscosity friction type silicon dioxide and a preparation method thereof. The high-cleaning-power and high-viscosity friction type silicon dioxide provided by the invention is prepared by taking a water glass solution with modulus of 2.5-3.5 and a sulfuric acid solution as reaction raw materials, adding octanol into a mother solution and adding fatty acid methyl ester ethoxylate at an aging stage for treatment. The high-cleaning-power and high-viscosity friction type silicon dioxide has a copper consumption value of 5.1-6.7 and an oil absorption value of 215-246g / 100g, and when the friction type silicon dioxide is applied to a toothpaste formula, the viscosity of a toothpaste body is 15-24wcp, so that under the same cleaning power, the toothpaste body has proper viscosity and fluidity, the low-temperature performance of the toothpaste body is improved, and the production cost of the toothpaste is reduced.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

Attapulgite honeysuckle flower green tea toothpaste and preparing method

InactiveCN100539995CQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsLow speedFriction effect

The invention discloses an attapulgite honeysuckle green tea toothpaste and a production method thereof. The main point of the technical scheme is that the production method of the attapulgite honeysuckle green tea toothpaste comprises steam cleaning, batching, low-speed stirring, crushing and beating, grinding, high-speed stirring, and vacuum degassing , canned as the finished product of attapulgite honeysuckle green tea toothpaste. Attapulgite Honeysuckle Green Tea Toothpaste consists of paste attapulgite clay, fresh tea leaves, fresh honeysuckle, sodium lauryl sulfate, potassium sorbate, borneol, and deionized water. Attapulgite honeysuckle green tea toothpaste has the characteristics of soft and delicate, clean and even, cool and refreshing, and can absorb and remove various odors in the oral cavity. The crushed and ground plant fiber can not only increase the consistency of the toothpaste paste, but also improve the friction effect and stability of the toothpaste. The invention is suitable for producing attapulgite honeysuckle green tea toothpaste, Chinese herbal medicine toothpaste and other medicine toothpaste.

Owner:贾剑

Electrically closed solenoid valve

ActiveCN106369205AReduce collisionCurved bigOperating means/releasing devices for valvesMagnetsSolenoid valveEngineering

The invention relates to an electrically closed solenoid valve. The solenoid valve is provided with a valve sleeve in which a pole core is fixedly arranged and an armature is arranged axially displaceably, wherein a pressure spring acts between the pole core and the armature in order to force a closing element cooperating with the armature into a valve seat. According to the invention, the valve is characterized in that a means for hydraulically damping the displacement of the armature is formed between the pole core and the armature.

Owner:ROBERT BOSCH GMBH

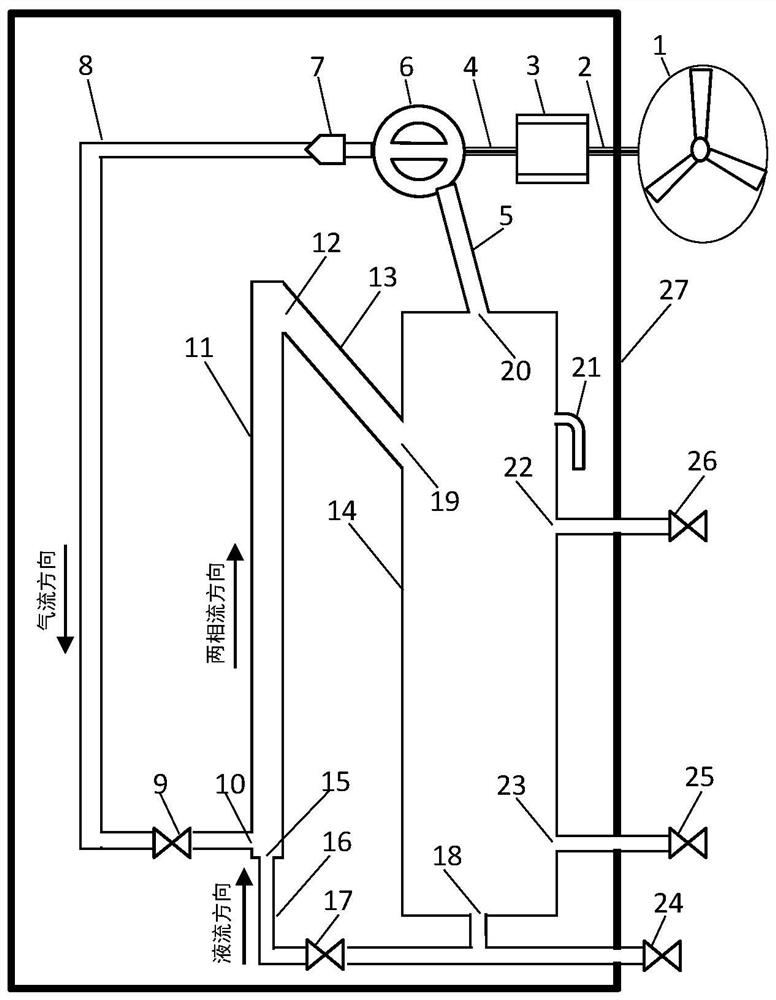

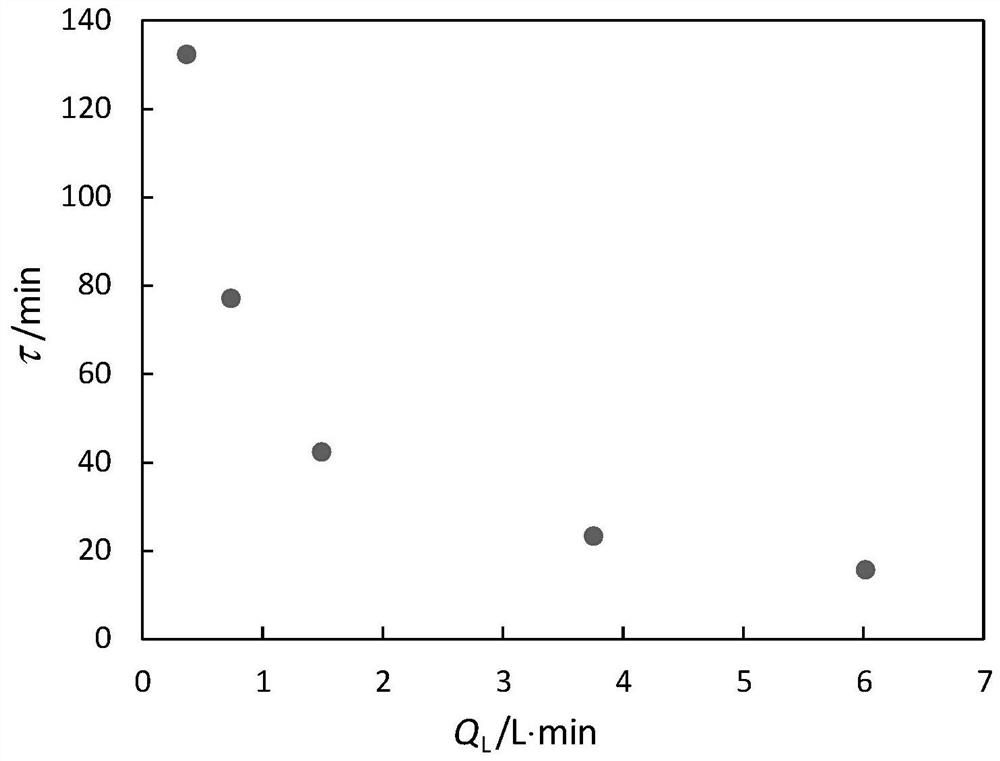

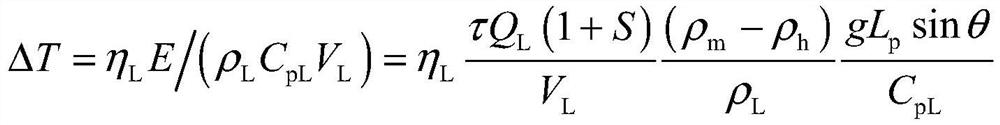

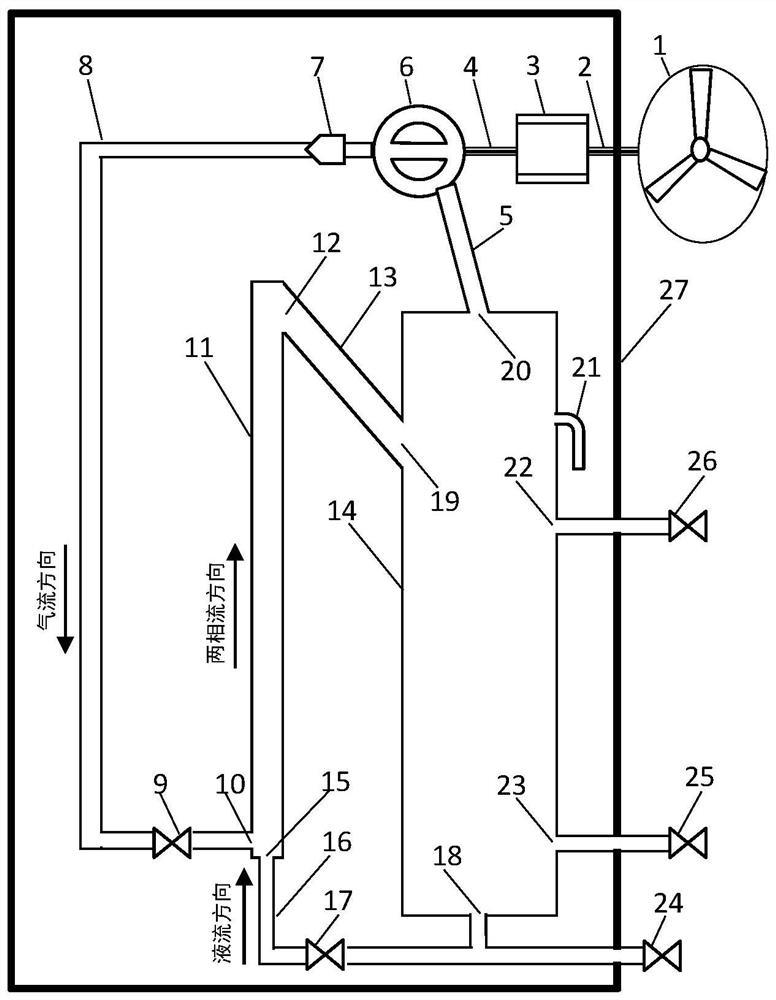

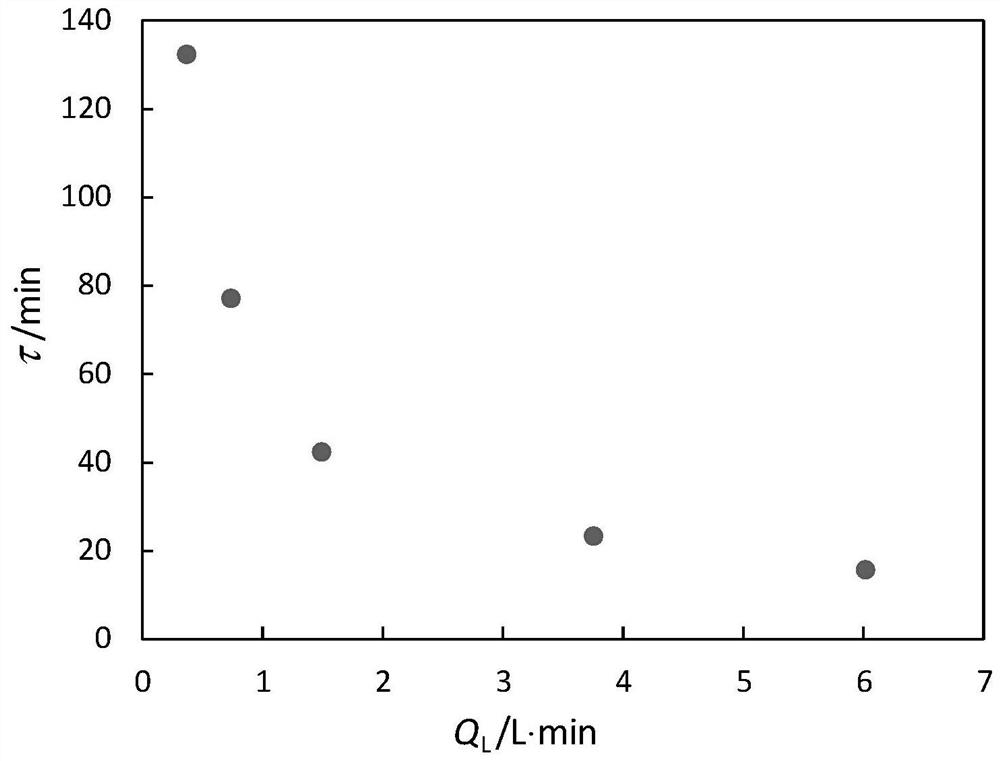

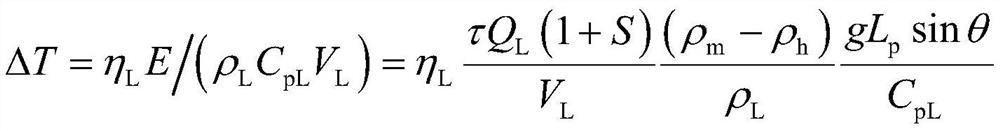

Wind-heating two-phase flow device and method

ActiveCN111852783AIncrease friction effectAchieve the purpose of heatingWind energy with garvitational potential energyEnergy storageImpellerEngineering

The invention discloses a wind-heating two-phase flow device and method. The device employs the high-intensity flow friction effect of a vertical pipe (or inclined pipe) gas-liquid two-phase slug flowunder the condition of a large gas-liquid ratio, converts the mechanical energy of wind power into heat energy, and achieves wind heating; and main body components of the device comprise a wind powerimpeller, a transmission, a movable scroll compressor disc, a fixed scroll compressor disc, a two-phase flow heating pipe and a gas-liquid separator, and auxiliary components comprise a connecting pipe and a valve. The wind power impeller and the transmission are connected with the movable scroll compressor disc and the static scroll compressor disc through shafts, replace a motor of a scroll compressor to drive the movable and static scroll compressor discs, and pressurize gas through wind power. The pressurized gas enters the two-phase flow heating pipe to form gas-liquid two-phase slug flow with a large gas-liquid ratio together with liquid in the two-phase flow heating pipe, wind energy is converted into heat energy through the high-strength friction effect, and a wind heating way isexpanded.

Owner:XI AN JIAOTONG UNIV

A wind-heated two-phase flow device

ActiveCN111852783BIncrease friction effectAchieve the purpose of heatingWind energy with garvitational potential energyEnergy storageVertical tubeImpeller

The invention discloses a wind-heated two-phase flow device. The invention utilizes the high-intensity flow friction effect of the gas-liquid two-phase slug flow in a vertical pipe (or an inclined pipe) under the condition of atmospheric liquid ratio to convert the mechanical energy of wind force Wind heating is realized as heat energy; the main components of the device include wind impellers, transmissions, scroll compressor dynamic and static discs, two-phase flow heating pipes, gas-liquid separators, and auxiliary components include connecting pipes and valves. The wind impeller and the transmission are connected to the dynamic and static discs of the scroll compressor via the shaft, and the wind impeller and the transmission replace the motor of the scroll compressor to drive the dynamic and static discs of the scroll compressor, and the gas is pressurized by wind force. The pressurized gas enters the two-phase flow heat pipe and the liquid in it forms a gas-liquid two-phase slug flow with an atmospheric-liquid ratio, and relies on the high-intensity friction effect to convert wind energy into heat energy, expanding the way of wind heating.

Owner:XI AN JIAOTONG UNIV

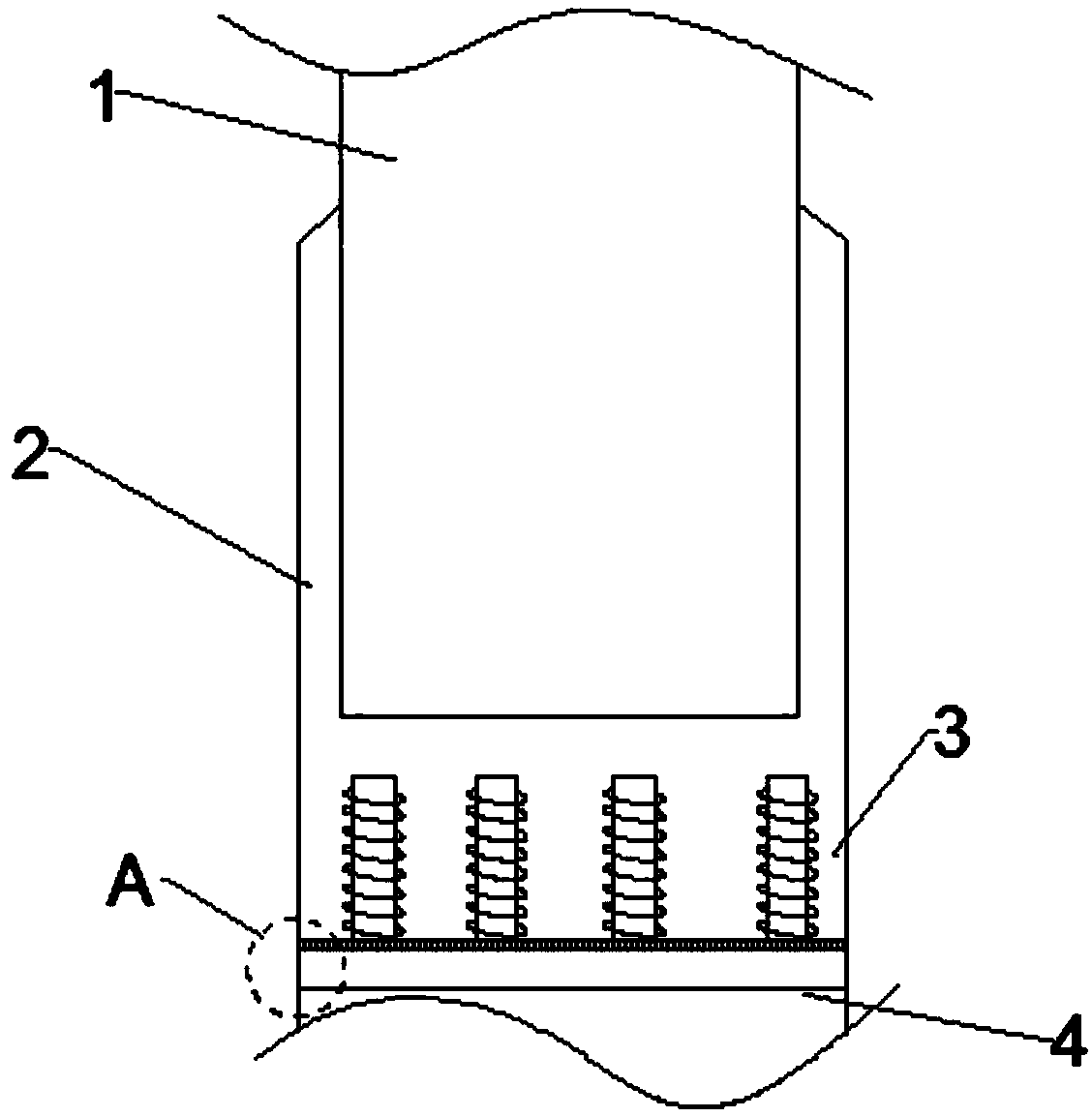

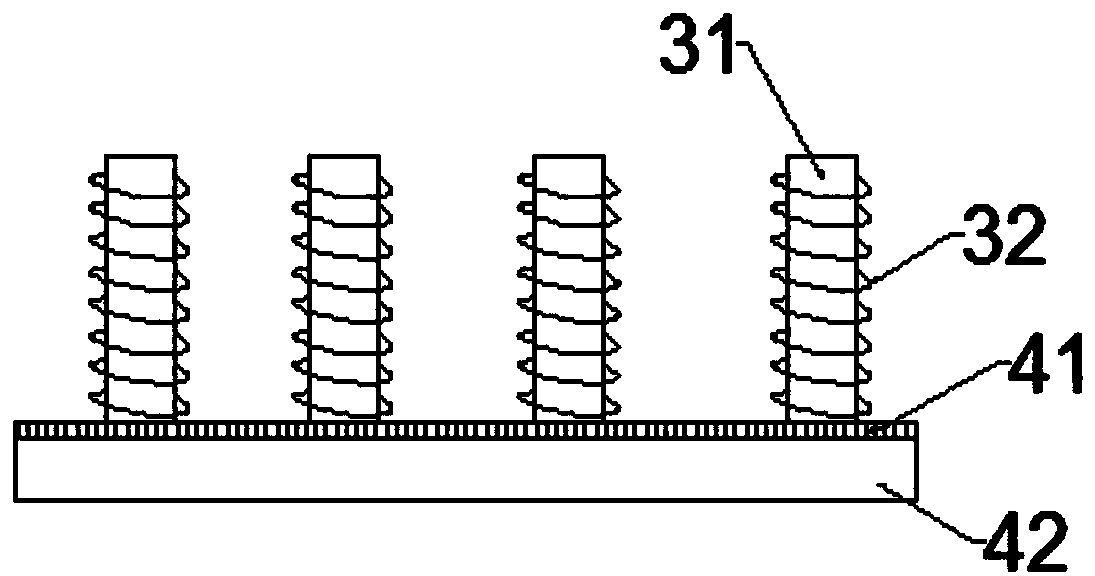

An elevator self-control buffer device

The invention provides an elevator self-control buffer device installed between the bottom of a lift car of an elevator and the bottom of an elevator outer case. The innovation points of the elevator self-control buffer device lie in that the buffer device comprises a jacking pressing device and a support device; the support device is fixedly installed below the jacking pressing device and is connected with the inner wall of the side face of the outer case, and a buffer support effect is achieved; when being subjected to weightlessness pressure, the jacking pressing device makes contact with the bottom of the lift car; the jacking pressing device comprises a jacking pressing column and a winding spring; the winding spring is spirally wound on the jacking pressing column, and a gap is reserved between the winding spring and the jacking pressing column in the width direction; and the height of the winding spring is smaller than that of the jacking pressing column. The elevator self-control buffer device can sense whether the elevator falls, then the elevator self-control buffer device is started through self control, the precision is high, the intelligent level is high, the survival rate of passengers during falling of the lift car is further increased, and the personal safety during accidental falling of the elevator is enhanced greatly.

Owner:朱爱民

Triboelectric generator based on wrinkled conductive film, preparation method and integrated structure

ActiveCN106877732BIncrease the output voltageIncrease output powerFriction generatorsHuman–machine interfaceFriction effect

The present invention provides a friction generator based on a folded conductive film. The friction generator comprises an upper friction layer which comprises an upper insulating layer (200) made of a flexible material and an upper electrode (100) on the upper insulating layer, a lower friction layer which comprises a substrate (400) made of a flexible material and a lower electrode (300) which is on the substrate and is made of a folded conductive film material. According to the folded design, a friction area and a friction effect are improved, thus a device with a same area has larger output voltage, in a same space structure, the output voltage and output power of the friction generator are effectively improved, the integration and promotion of multiple friction generators are facilitated, the scalability of a device is also improved through folded electrodes in upper and lower positions, thus a power generation mode is broadened, power can be generated through pressure, power can be generated through drawing and bending, the versatility of the device is enhanced, and the application of the friction generator in the aspects of complex environment and the man-machine interface is facilitated.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Silica for high load capacity and high cleaning friction type dentifrice and preparation method thereof

ActiveCN113350205BIncrease friction effectEasy to cleanCosmetic preparationsSilicaSulfonateSilicon dioxide

The invention belongs to the technical field of silicon dioxide, and in particular relates to silicon dioxide for high-loading, high-cleaning and friction-type tooth powder and a preparation method thereof. The invention adopts the water glass with a modulus of 1.5-3.5 to react with the sulfuric acid of a certain concentration under the action of sodium dodecylsulfonate to prepare the silicon dioxide for tooth powder with high load capacity and high cleaning and friction type. The high-loading, high-cleaning, friction-type dentifrice silica provided by the present invention is a high-grinding, high-adsorption precipitated silica with a large particle size, which is not easy to disperse and has a water absorption of 120-180mL / 100g, and is applied to dentifrices. It can prevent moisture and prevent the tooth powder from absorbing moisture and agglomerating during the storage of the tooth powder. In addition, the silicon dioxide for high-loading and high-cleaning abrasive tooth powder provided by the present invention has a high loading capacity and can improve the performance of the tooth powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

Robot electronic skin based on capacitance and friction power generation principle and preparation method thereof

PendingCN113970391AHigh sensitivityIncrease friction effectForce measurementFriction generatorsCapacitanceTactile perception

The invention discloses a robot electronic skin based on a capacitance and friction power generation principle. The robot electronic skin is mainly formed by tightly assembling a flexible abrasive paper modified layer, an upper substrate layer, an upper electrode layer, a lower substrate layer and a lower electrode layer in sequence from top to bottom. The invention provides a manufacturing method of the robot electronic skin based on the capacitance and friction power generation principle. The robot electronic skin can cover the surface of a robot to serve as a flexible device which endows the electronic skin with the tactile perception capability, so that the robot can also perceive the tactile sense, and the robot electronic skin has wide application prospects.

Owner:陕西中建建乐智能机器人股份有限公司

Halloysite Chinese herbal medicine tooth powder

InactiveCN108514540ASmall friction hardnessNo grittinessCosmetic preparationsToilet preparationsBrush toothBletilla striata

The invention relates to a halloysite Chinese herbal medicine tooth powder including the following raw materials: active halloysite powder, cuttle-bone, bletilla striata, pollen pini, lotus roots, licorice roots, borneol, lauryl sodium sulfate and water. By activating the halloysite powder, the active halloysite powder, as well as other raw materials, is subjected to wet-milling in a ball millingmachine, then the materials are dried and pulverized to prepare the halloysite Chinese herbal medicine tooth powder. The tooth powder has good stability and is free of caking, has a refreshing, soft and fine mouth feel, can effectively reduce abrasion on enamel on tooth surface during brushing teeth, and is suitable for removing bad breath and preventing oral diseases.

Owner:SHAANXI SCI TECH UNIV

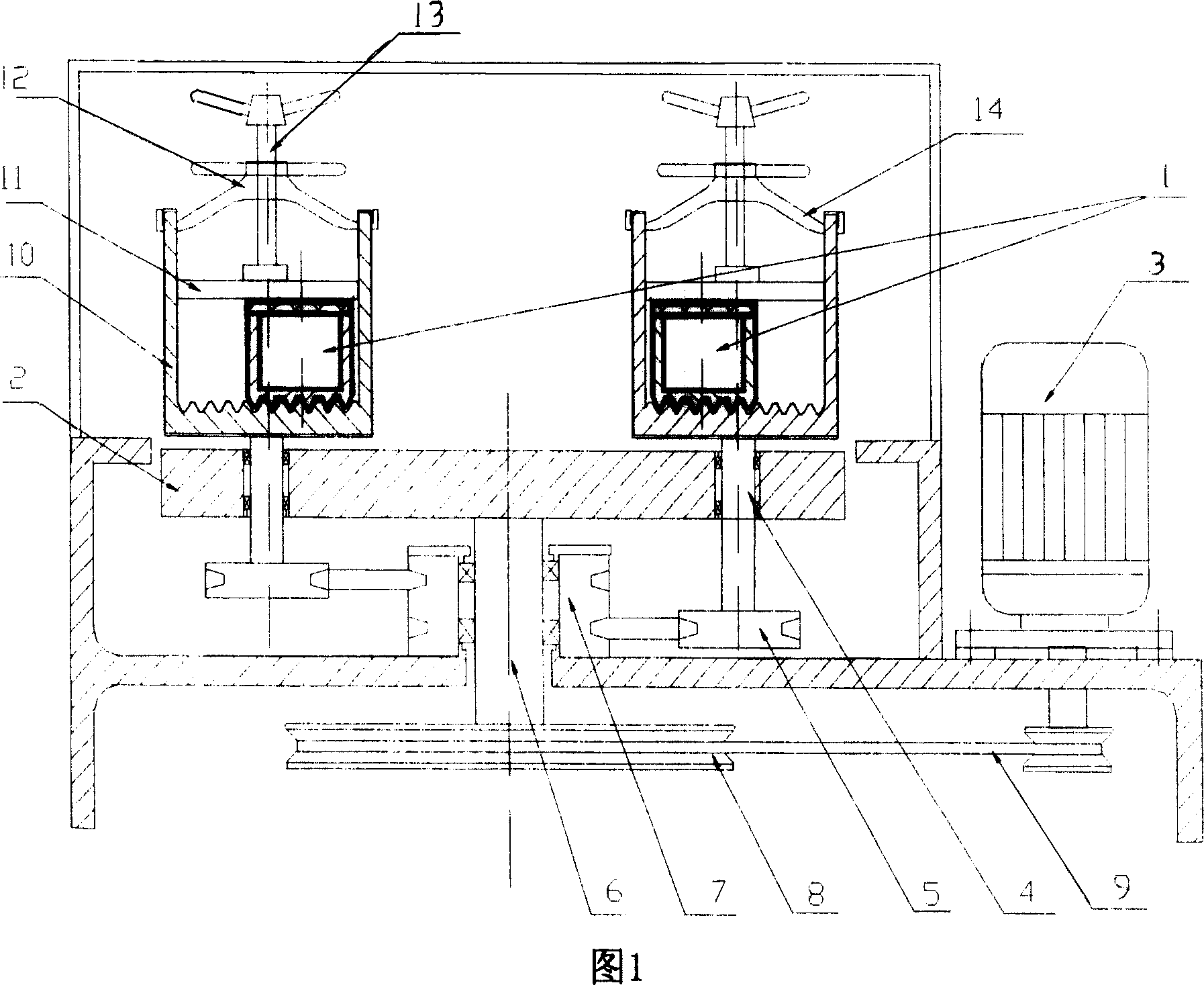

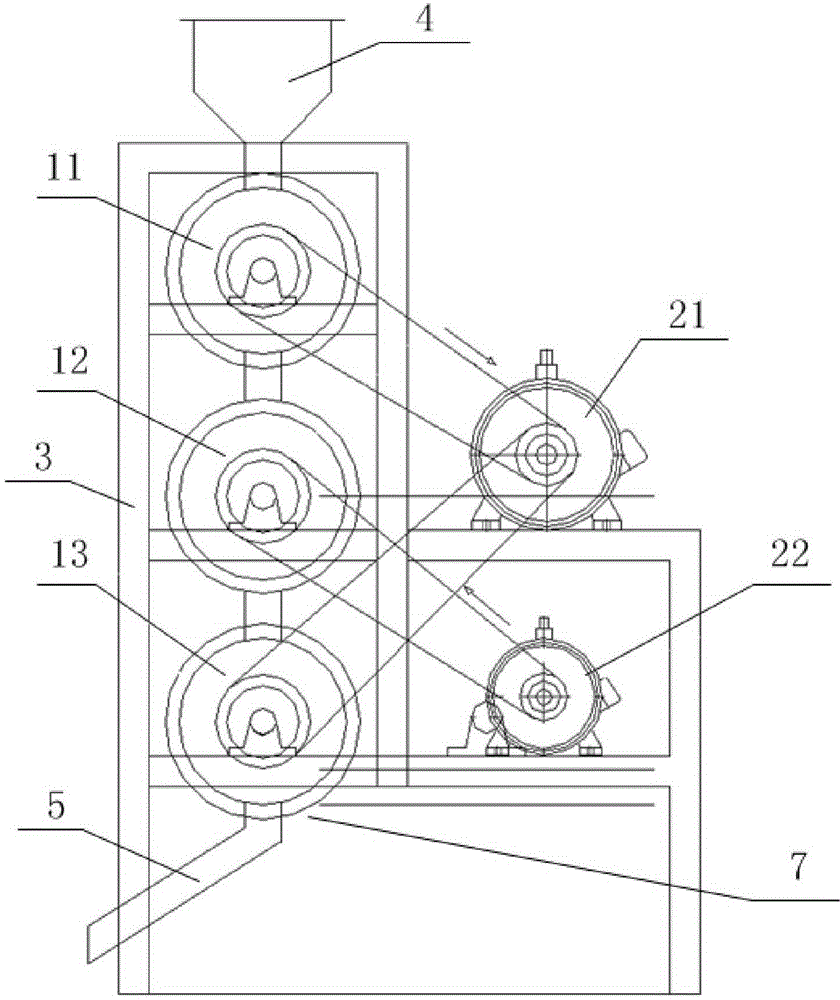

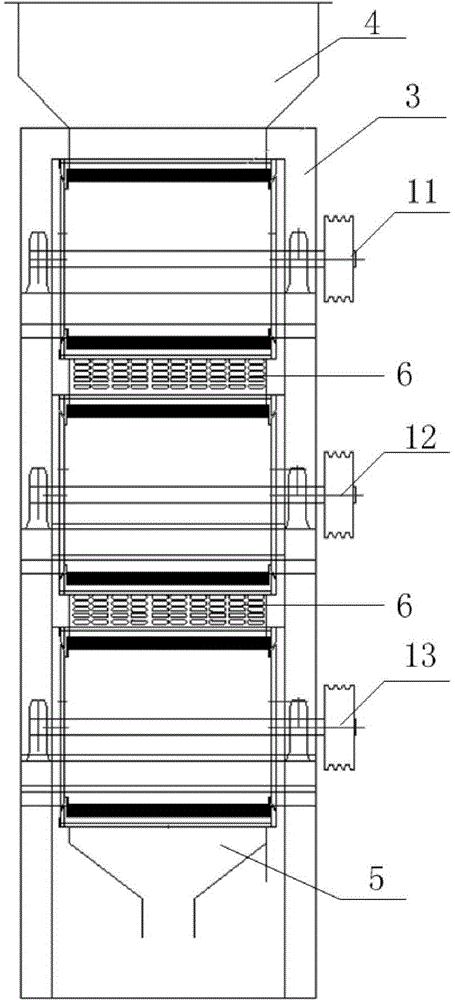

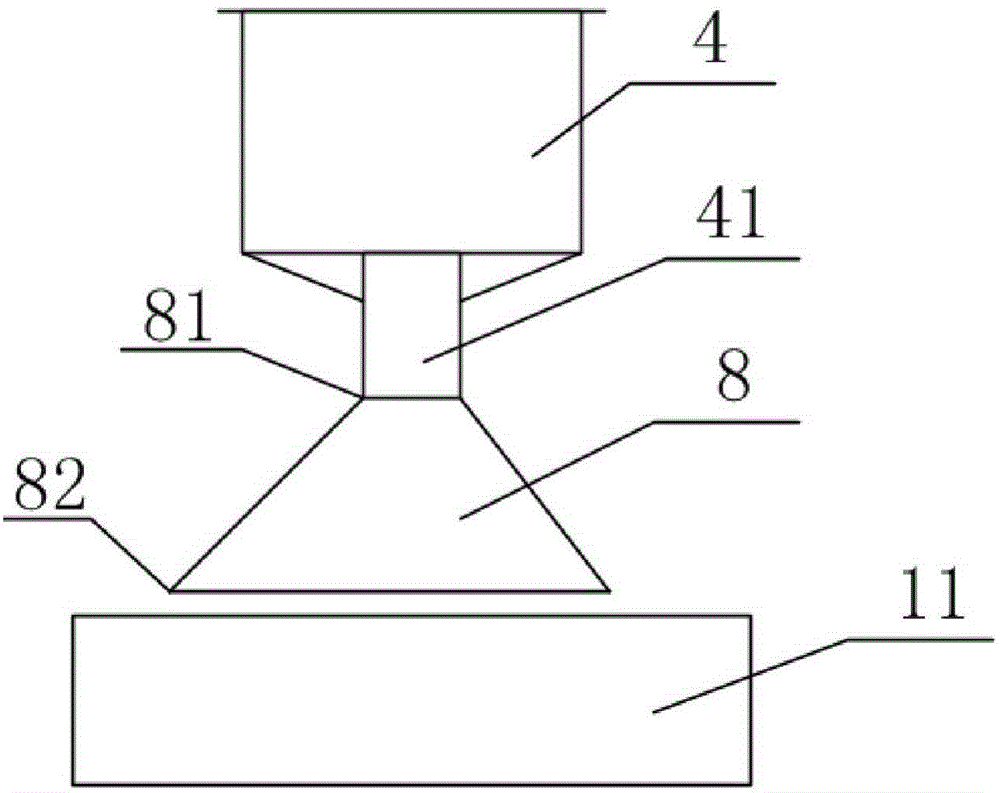

Vertical type cotton seed polishing machine

ActiveCN103975667AIncrease friction effectEasy to operateSeed and root treatmentDrive motorHigh heat

The invention discloses a vertical type cotton seed polishing machine which comprises a polishing machine shell, wherein a material feeding hopper is arranged on the upper part of the shell, and the lower part of the shell is provided with a material outlet and an impurity discharging pipe; the vertical type cotton seed polishing machine further comprises a first brush roller, a second brush roller and a third brush roller; the first brush roller, the second brush roller and the third brush roller are arranged from top to bottom, and roller shafts are horizontally mounted in the polishing machine shell; the vertical type cotton seed polishing machine further comprises a driving motor and a screen drum; the driving motor is used for driving the first brush roller, the second brush roller and the third brush roller to rotate; the screen drum encircles the brush rollers and is provided with an upper opening and a lower opening; an impurity removal cavity is formed between the screen drum and the polishing machine shell; the impurity discharging pipe is communicated with the impurity removal cavity; the material outlet is formed in the lower opening of the screen drum. The brush rollers of the vertical type cotton seed polishing machine disclosed by the invention are transversely arranged; the problems that cotton seeds are easily stacked, the high temperature can be generated due to friction, the crushing rate is high, residual flocks cannot be completely cleaned and the like are solved.

Owner:SHIHEZI DEV ZONE TIANZUO SEED MACHINERY

Attapulgite jasmine flower green tea toothpaste and preparation method thereof

InactiveCN100584310CQuality improvementImprove adsorption capacityCosmetic preparationsToilet preparationsLow speedAdditive ingredient

The invention discloses attapulgite / jasmine flower / green tea toothpaste and a production method thereof. The technical proposal is that: the production method comprises the following steps: steaming for enzyme deactivation, preparing ingredients, low-speed stirring, pulverization and pulping, milling, high-speed stirring, vacuum degassing and packaging. Through the steps, finished products of attapulgite / jasmine flower / green tea toothpaste are obtained. The attapulgite / jasmine flower / green tea toothpaste contains pasty attapulgite clay, fresh green tea, fresh jasmine flower, fresh magnolia flower, sodium dodecylsulfate, potassium sorbate, borneol and deionized water. The invention utilizes pasty attapulgite clay as a major ingredient, has no addition of abrasives, adhesives and humectant, and can improve toothpaste quality while reducing production cost. Pulverized and milled Plant fibers can not only increase the viscosity of the toothpaste but also improve the abrasion effect and stability of the toothpaste. The inventive mothed is suitable for the production of attapulgite / jasmine flower / green tea toothpaste, herbal toothpaste and other medicinal toothpaste.

Owner:许盛英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com