Wind-heating two-phase flow device and method

A phase flow and wind power technology, which is applied in the field of two-phase flow devices induced by wind power, can solve the problems of high equipment cost, wear of the rotating shaft, and attenuation of solid material properties, and achieve high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

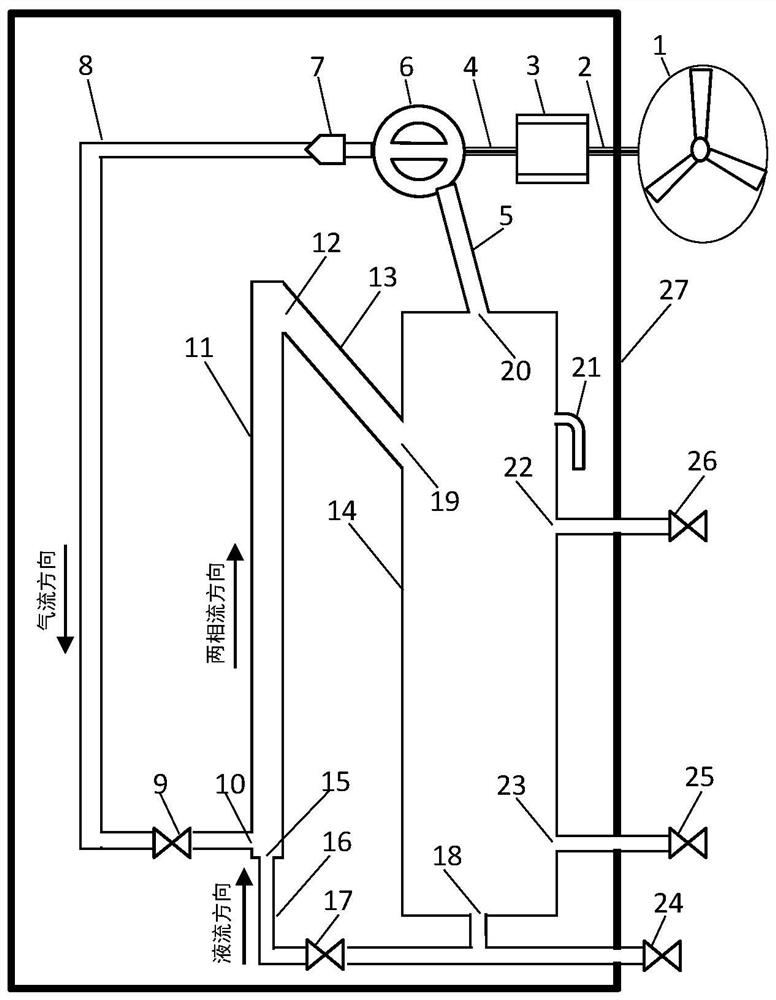

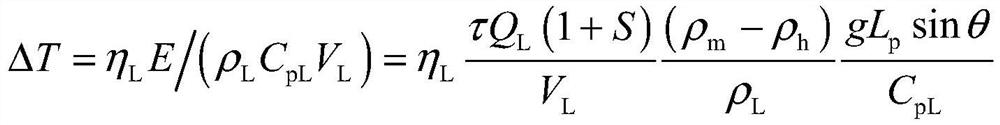

[0073] In this embodiment, the two-phase flow heat pipe 11 is a vertical pipe (sinθ=1) with a length of 2 m and an inner diameter of 0.04 m. The liquid is water, density ρ L =998kg·m -3 , constant pressure specific heat C pL =4200J·kg -1 ·℃ -1 ;The gas is air, density ρ G =1.3kg·m -3 , constant pressure specific heat C pG =1005J·kg -1 ·℃ -1 ; Make the liquid delivery valve 25 and the liquid-repelling valve 24 remain closed, open the replenishment valve 26, and inject 10 liters (0.01m 3 ), and then open the liquid regulating valve 17 to form a liquid column with a height of 0.9m in the two-phase flow heat pipe 11. By adjusting the gas flow rate and liquid flow rate, a slug flow with a gas-liquid ratio of S=100 is formed to generate a high-intensity flow friction effect, convert the mechanical energy of wind force into heat energy, and calculate the liquid heat absorption rate η L = 0.97.

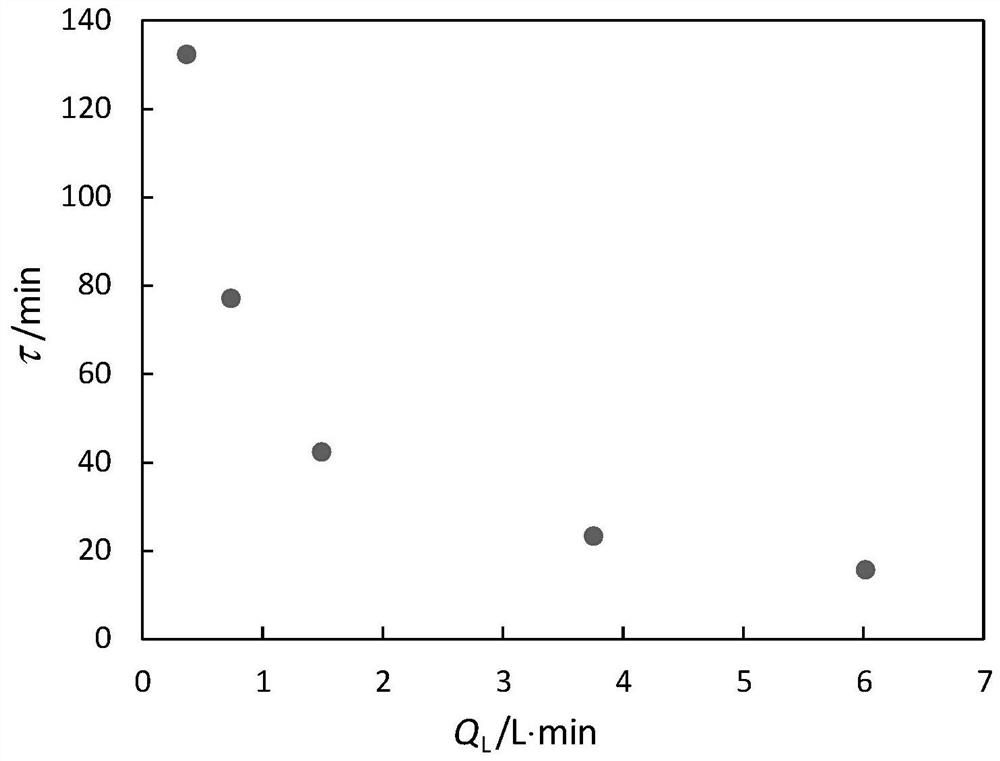

[0074] figure 2 The required time τ and water flow Q are given when heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com