Vertical type cotton seed polishing machine

A polishing machine, cotton seed technology, applied in the direction of seed and rhizome treatment, application, agriculture, etc., can solve the problems of cotton seed burnout, cotton seed damage, accumulation, etc., and achieve easy replacement, increased friction effect, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0034] The technical problem to be solved by the embodiments of the present invention is to overcome the problems that cotton seeds are easy to accumulate when the existing vertical grinder is working, high temperature damages cotton seeds due to friction, high cotton seed breakage rate, and unclean removal of velvet.

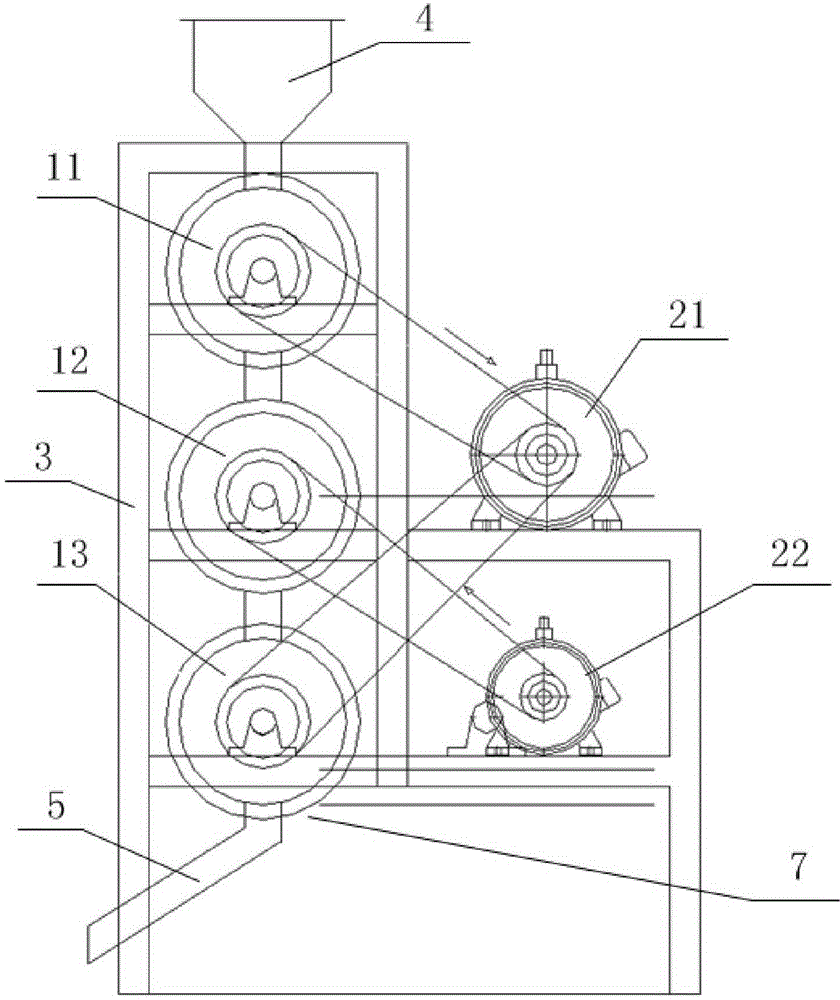

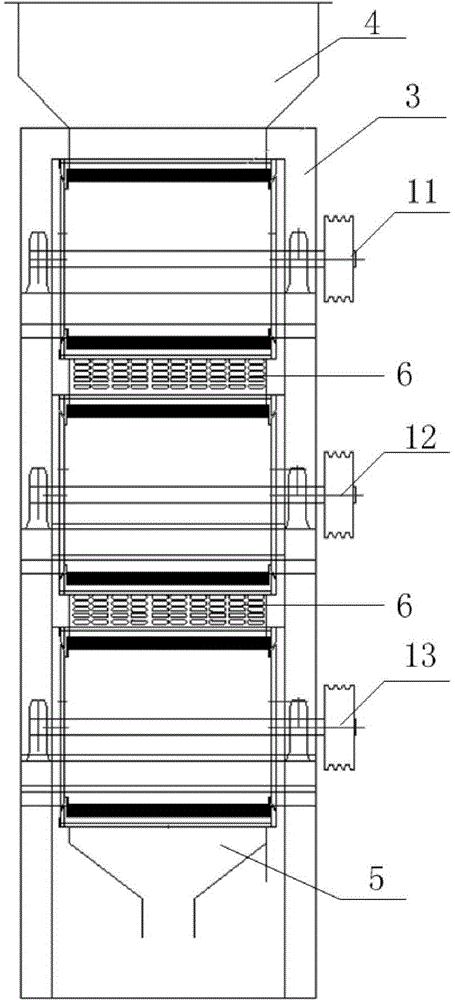

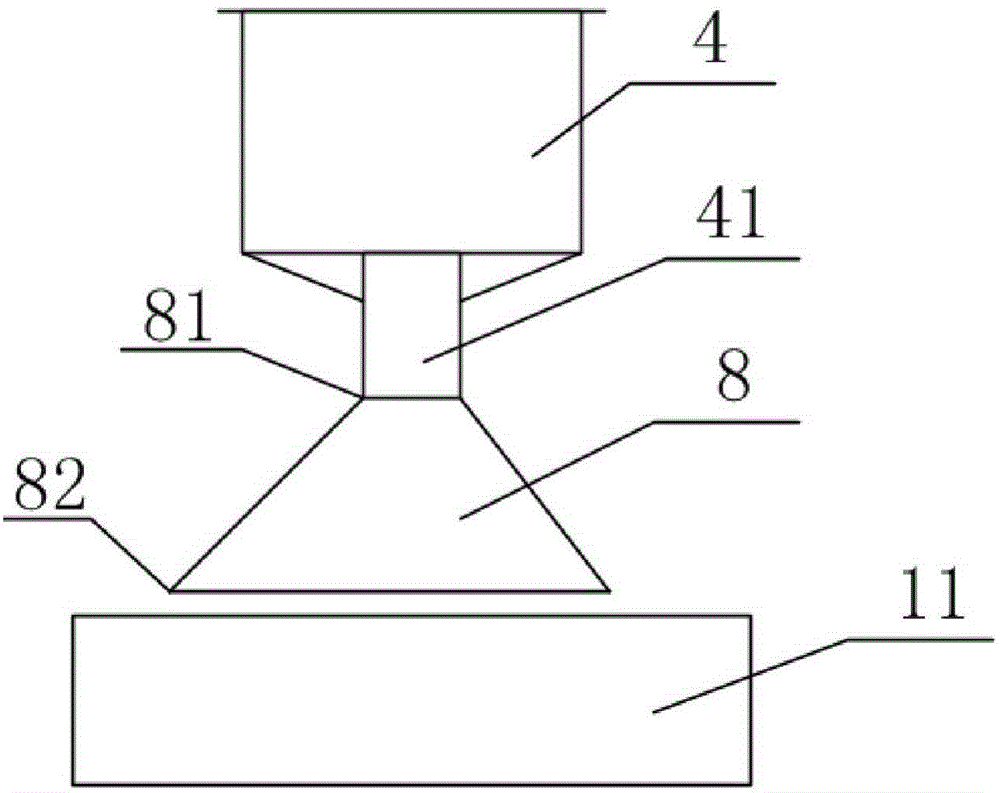

[0035] Such as figure 1 As shown, it is an overall schematic diagram of a vertical cotton seed polisher according to an embodiment of the present invention. It includes a grinder housing 3, the upper part of the housing has a feed hopper 4, the lower part has a discharge port 7 and an impurity discharge pipe 5, and it also includes:

[0036] The first brush roll 11, the second brush roll 12 and the third brush roll 13, the first brush roll, the second brush roll and the third brush roll are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com